The crisp touch of a page, the smoothness of a glossy photograph. Despite using paper for so much throughout our lives, many do not know much about how paper is created besides the vague notion that it comes from trees. In fact, there are several steps for paper to transition from the forest into your hands.

Chemical Pulping

When a bolt (or short section) of wood arrives at a pulp mill, it is first debarked by tumbling in steel drums. It then moves to a wood chipper and is screened for size before continuing onto the fiber separation stage. A single pine tree can produce approximately 80,500 sheets of paper. (HSW)

The chips are kept in a digester, where they are treated with the appropriate chemicals and steam in order to separate out the good fibers from the rest. This pulp is then sent to a pressure tank from which steam and volatile substances are removed. Chemical pulp is used for high quality papers.

Mechanical Pulping

The mechanical pulping process is similar to that of chemical pulping as both begin with chipping the wood. Instead of heading to a digester, the pulp in this process then heads to a refiner. Mechanical pulping can be broken into two categories: ground pulp and thermo-mechanical pulp. Both of these can be used for lower quality papers, such as newsprint.

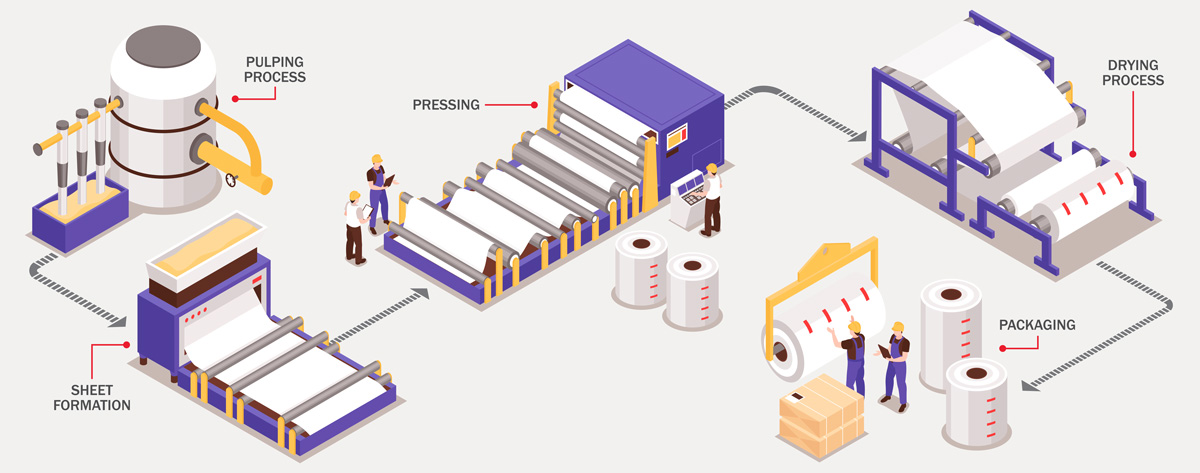

Sheet Formation & Processing

Pulp contains a number of discolorants, and needs to be bleached in order to have the light color preferred for many paper products. The bleaching process varies depending upon the type and condition of pulp. The pulp may then be further refined by adding water to the slurry mixture, cleaning it in a cyclone cleaner, and screening it with centrifugal screens. The wet mixture is fed into a paper-forming machine where it is distributed evenly. It is pressed, dried, and wound onto large rolls for packaging and shipment.

Did you know? The U.S. Pulp and Paper Industry produces 78 million tons of paper per year!

Why Dwyer

Dwyer Instruments, Inc. offers several product solutions for monitoring the flow, level, and pressure in pulp and paper manufacturing applications. Ultrasonic level sensors, like the Model ULSL, can be used to provide non-contact, continuous level measurement of fluids in chemical processing applications. Because it uses a non-contact technology, it doesn’t have moving parts to wear or jam, or get coated in pulp mixtures. Additionally, the ULSL has automatic temperature compensation for accurate and reliable measurements. Its mapping software makes the effective measuring surface only a 3” (76.2 mm) diameter column, with no concern of ladders, pipes, or other tank intrusions.

If you have any questions about selecting products for your application, the Dwyer Applications Engineers are available to assist by phone at (219) 879-8868 x6402, or by email at tech@dwyermail.com.

—

Sources:

https://extension.okstate.edu/fact-sheets/basics-of-paper-manufacturing.html