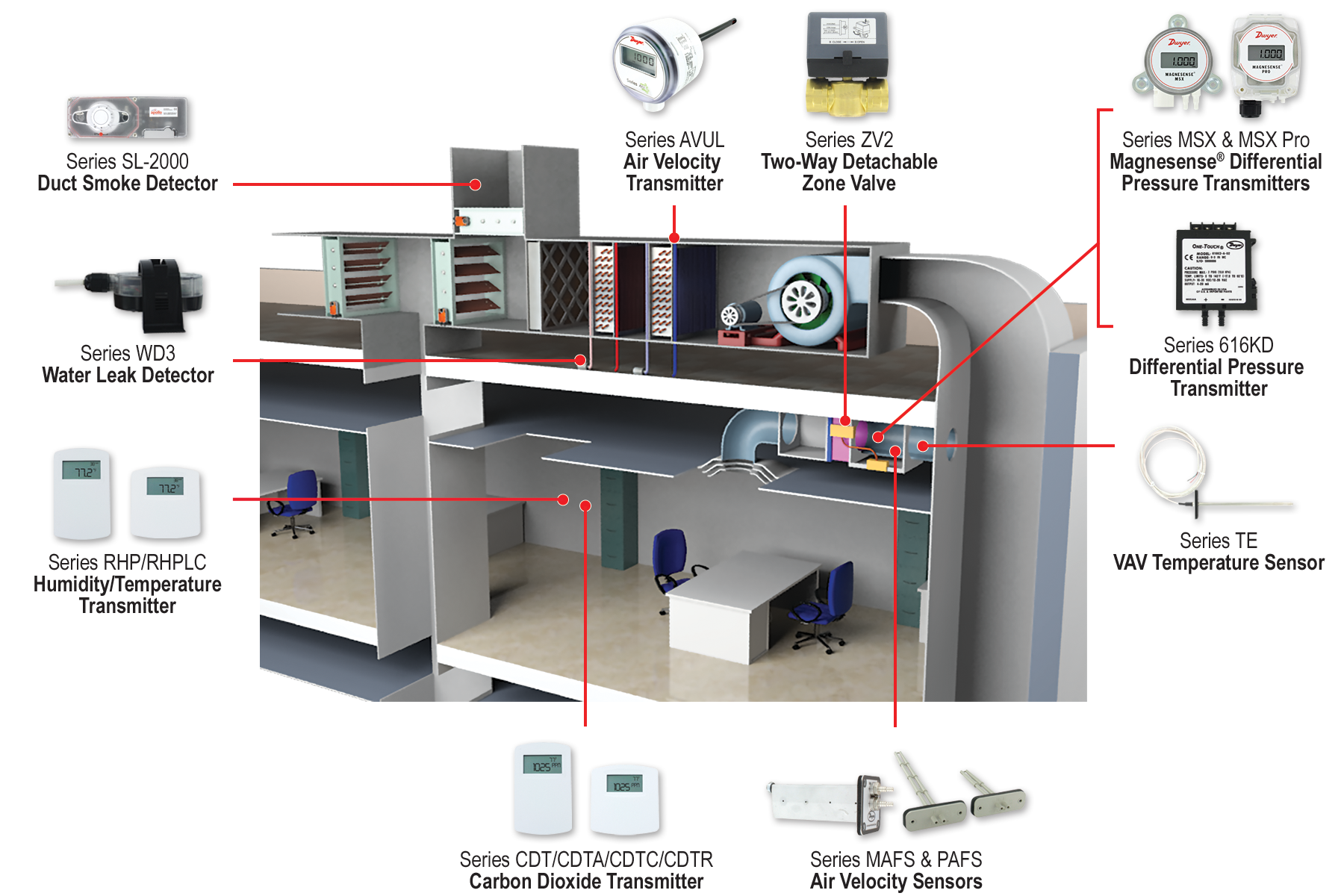

Picture this: you walk into an office building on a hot summer day. As the door closes behind you, you immediately feel the temperature change. It’s cool and refreshing, thanks to the terminal units working diligently behind the scenes. Terminal units, while often unseen and unheard, play a crucial role in maintaining a comfortable environment in various buildings, from offices to schools and hospitals. Let’s explore these components, the challenges they address, and how Dwyer’s range of products helps conquer these challenges.

Picture this: you walk into an office building on a hot summer day. As the door closes behind you, you immediately feel the temperature change. It’s cool and refreshing, thanks to the terminal units working diligently behind the scenes. Terminal units, while often unseen and unheard, play a crucial role in maintaining a comfortable environment in various buildings, from offices to schools and hospitals. Let’s explore these components, the challenges they address, and how Dwyer’s range of products helps conquer these challenges.

Continue reading “Exploring Terminal Units: Dwyer’s Solutions for Better Indoor Environments and Optimal Performance”

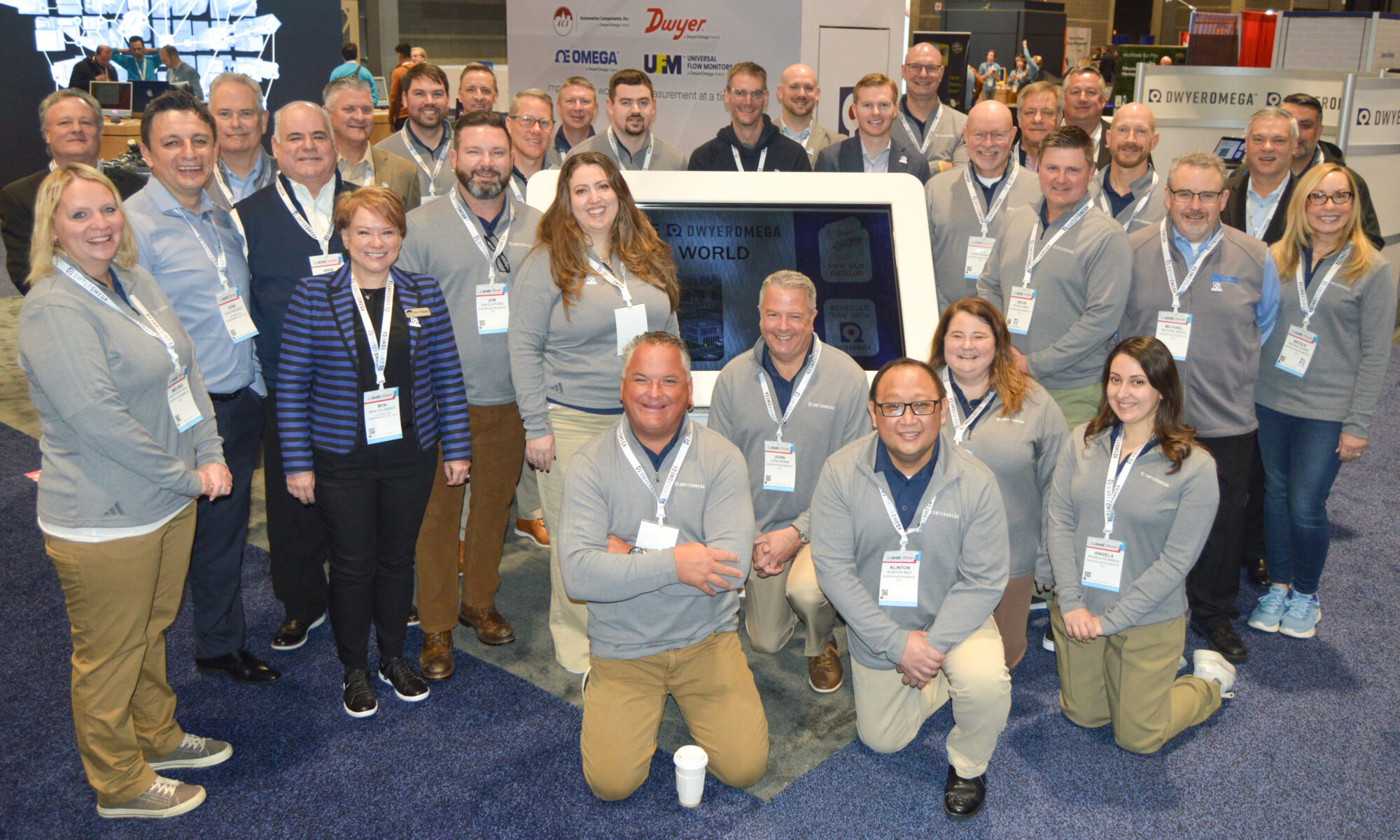

Reflections: AHR Expo, World of Concrete, and What’s Next!

The curtain has fallen on two fantastic tradeshows, AHR Expo and World of Concrete, and we’re still buzzing with excitement! We want to extend a heartfelt thank you to all the amazing customers, partners, and teammates who made these events unforgettable. Continue reading “Reflections: AHR Expo, World of Concrete, and What’s Next!”

How Thermal Flowmeters Work

Thermal flowmeters use the thermal properties of the fluid to measure the flow of a fluid flowing in a pipe or duct. In a typical thermal flowmeter, a measured amount of heat is applied to the heater of the sensor. Some of this heat is lost to the flowing fluid. As flow increases, more heat is lost. The amount of heat lost is sensed using temperature measurement(s) in the sensor. The transmitter uses the heat input and temperature measurements to determine fluid flow. Most thermal flowmeters are used to measure gas flows. Thermal flowmeters represent 2% of global flowmeter sales. Continue reading “How Thermal Flowmeters Work”

Thermal flowmeters use the thermal properties of the fluid to measure the flow of a fluid flowing in a pipe or duct. In a typical thermal flowmeter, a measured amount of heat is applied to the heater of the sensor. Some of this heat is lost to the flowing fluid. As flow increases, more heat is lost. The amount of heat lost is sensed using temperature measurement(s) in the sensor. The transmitter uses the heat input and temperature measurements to determine fluid flow. Most thermal flowmeters are used to measure gas flows. Thermal flowmeters represent 2% of global flowmeter sales. Continue reading “How Thermal Flowmeters Work”

Mitigating Methane in Landfills

In the ongoing narrative of environmental conservation, few adversaries are as concerning as methane gas emissions from landfills. This potent greenhouse gas poses a substantial threat to both our climate and community health, demanding immediate attention and sustainable solutions.

In the ongoing narrative of environmental conservation, few adversaries are as concerning as methane gas emissions from landfills. This potent greenhouse gas poses a substantial threat to both our climate and community health, demanding immediate attention and sustainable solutions.

Landfills contain several different gases and volatile organic compounds (VOCs) caused by the breakdown of waste, with methane and carbon dioxide making up over 90% of them (health.ny.gov). Once waste breaks down and forms landfill gas and particulates, it can potentially spread to nearby buildings or structures through openings like cracks, windows, or ventilation systems and settle in areas of poor ventilation like basements or crawl spaces (health.ny.gov). Continue reading “Mitigating Methane in Landfills”

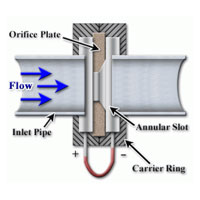

Flow Measurement with Orifice Plates

Dwyer Instruments offers many types of flow measuring products including orifice plates, which are used as a flow sensing element with a differential pressure monitor.

Orifice plates are a primary flow element, detecting the flow of a fluid passing through the plate by sensing the pressure drop across the plate. When a fluid flows through a restriction in a pipe, it creates a pressure difference between upstream and downstream of the restriction. This pressure difference is proportional to flow rate according to Bernoulli’s principal, similar to a Pitot tube. Orifice plates are commonly used as they are simple to use, low cost, work with gases or liquids, and require low maintenance. Adversely, they do have large pressure losses with about 50% of the pressure drop not recoverable. Continue reading “Flow Measurement with Orifice Plates”