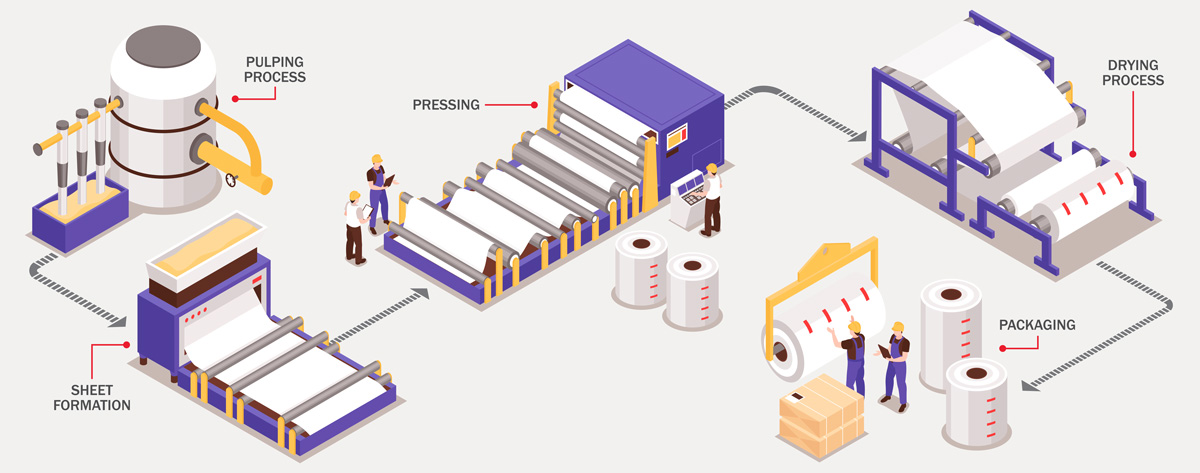

The crisp touch of a page, the smoothness of a glossy photograph. Despite using paper for so much throughout our lives, many do not know much about how paper is created besides the vague notion that it comes from trees. In fact, there are several steps for paper to transition from the forest into your hands.

Storing Food Safely: How Dwyer Can Help Meet HACCP Refrigeration Control Standards

Unless it’s recently stopped running (or run away), you probably haven’t paid much attention to your refrigerator lately. Despite enjoying status among the largest and most frequently used appliances in your home, the refrigerator is a bit of an unsung hero, quietly humming away in your kitchen, keeping lettuce crisp and ice cream velvety smooth. But refrigeration is about so much more than fresh greens and tasty frozen treats; the humble fridge is also the first line of defense against foodborne illness.

Unless it’s recently stopped running (or run away), you probably haven’t paid much attention to your refrigerator lately. Despite enjoying status among the largest and most frequently used appliances in your home, the refrigerator is a bit of an unsung hero, quietly humming away in your kitchen, keeping lettuce crisp and ice cream velvety smooth. But refrigeration is about so much more than fresh greens and tasty frozen treats; the humble fridge is also the first line of defense against foodborne illness.

Historical trivia: The first practical, ice-cooled refrigerator rail car was invented in Chicago for Swift & Co. in 1878, revolutionizing the meat packing industry and changing the way we eat forever. (Wikipedia – Gustavus Franklin Swift)

According to the CDC, there are 31 pathogens known to cause foodborne illness. In the United States, these pathogens, including norovirus, salmonella, and even Staphylococcus aureus (Staph), are responsible for an estimated 9.4 million cases annually. Many of these cases go beyond typical food poisoning symptoms, resulting in 56,000 hospitalizations and 1,300 deaths.

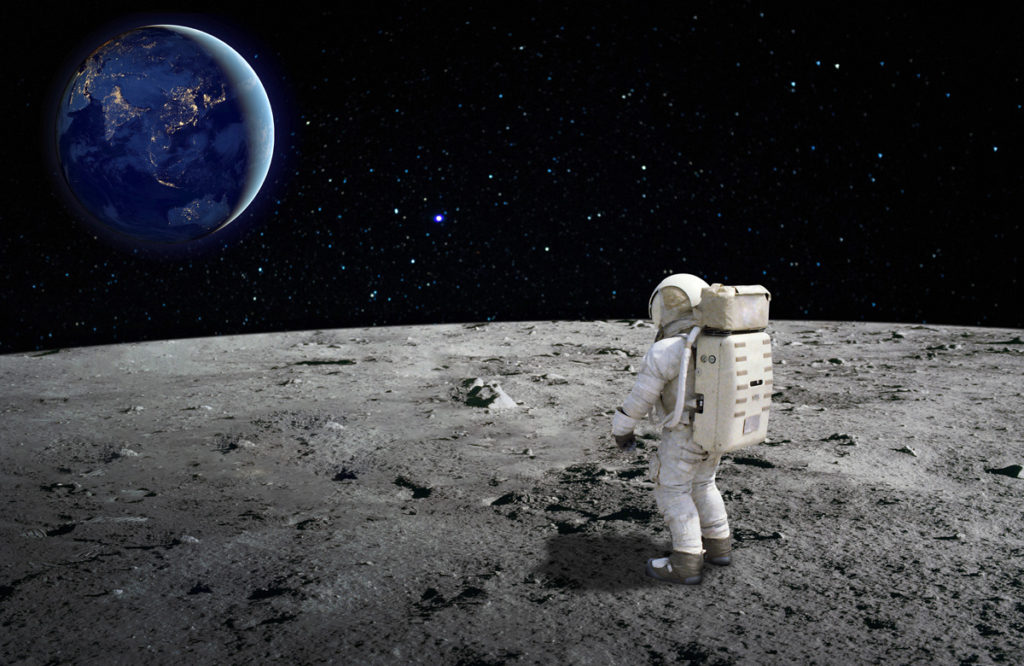

Protecting Lunar Samples from Contamination

For as long as humanity has been looking up at the sky, we’ve wondered what lay beyond the ground beneath our feet. When the astronauts of the Apollo 11 mission took their first steps in 1969, the world saw a future filled with spaceships and rockets. We dreamed of a lack of gravity, fueled by grainy images on a TV and the words of Neil Armstrong: “That’s one small step for a man, one giant leap for mankind.” The Apollo 17 mission in 1972 was the last trip to the moon for several decades.

Lunar science has become a thriving field of study which helps to define our knowledge of the formation of the universe. The lunar rock and soil samples gathered by Apollo astronauts are still studied to this day.

Continue reading “Protecting Lunar Samples from Contamination”

Continue reading “Protecting Lunar Samples from Contamination”

Monitoring Center Pivot Irrigation Systems

You arrive at a large field, small sprouts peeking out of the soil. At the center of the field lies a structure connected to a span of pipe from which sprinklers hang. Trusses brace and support its weight. From the air, this field would appear to be a perfectly circular patch of green.

You arrive at a large field, small sprouts peeking out of the soil. At the center of the field lies a structure connected to a span of pipe from which sprinklers hang. Trusses brace and support its weight. From the air, this field would appear to be a perfectly circular patch of green.

Center pivot irrigation systems are one of many ways to distribute water to crops. As its name suggests, this method involves rotating around a central pivot point. When the machine rotates, it releases water from the sprinklers and irrigates crops. (Agrivi.com) By using this system, farmers can ensure a uniform application of water across an entire field. Continue reading “Monitoring Center Pivot Irrigation Systems”

Measuring Thermal Energy in Hydronic Systems

So you’ve decided to track how much energy your HVAC system consumes in order to increase the system’s energy efficiency — great! But how will you do it? There are multiple methods that can be used to measure thermal energy in hydronic systems. We’ve outlined several methods below to make it easier for you to select the best technology for your application.

![]() Measuring thermal energy requires three components: a fluid flow sensor, two temperature sensors (one for inlet temperature, one for outlet temperature), and a calculator. Although thermal energy can technically be measured without a calculator, doing an energy calculation by hand is very complex and can introduce manual calculation error into the measurement. For that reason, we recommend incorporating a calculator into your system for the most accurate energy measurements. This calculator can be either an independent BTU controller, part of your building management system, or integral to a complete thermal energy system. A complete system includes a flowmeter, temperature sensors, and a calculator that are all calibrated together, eliminating the need for multiple pieces of equipment. Continue reading “Measuring Thermal Energy in Hydronic Systems”

Measuring thermal energy requires three components: a fluid flow sensor, two temperature sensors (one for inlet temperature, one for outlet temperature), and a calculator. Although thermal energy can technically be measured without a calculator, doing an energy calculation by hand is very complex and can introduce manual calculation error into the measurement. For that reason, we recommend incorporating a calculator into your system for the most accurate energy measurements. This calculator can be either an independent BTU controller, part of your building management system, or integral to a complete thermal energy system. A complete system includes a flowmeter, temperature sensors, and a calculator that are all calibrated together, eliminating the need for multiple pieces of equipment. Continue reading “Measuring Thermal Energy in Hydronic Systems”