We recently met with a customer in India who needed to replace a flowmeter in an Energy Monitoring System (EMS) application in a commercial shopping mall.

We recently met with a customer in India who needed to replace a flowmeter in an Energy Monitoring System (EMS) application in a commercial shopping mall.

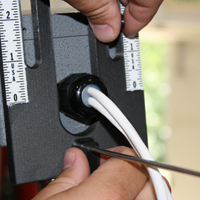

Energy Monitoring Systems (EMS) continuously monitor and record chiller operating data. The EMS utilizes flowmeters installed in each chiller to measure flow. Temperature sensors are located in the inlet and outlet of the evaporators and condensers. A kWh meter measures the power consumption of each chiller. The data from each of these devices is collected and recorded within the control panel, which is then sent to a report generated in the cloud. This kind of system can accurately report the data used to manage energy and operating costs.

Because the space was occupied, the application couldn’t be shut down for maintenance or repairs. This meant that we needed to look into alternative solutions that wouldn’t affect system operations with unnecessary downtime. Continue reading “Flowmeter Used in an Energy Monitoring System Application”

Selecting the correct flowmeter can be a challenging task, and the variety of flow technology options can make the decision even more difficult. By keeping the benefits and drawbacks of each type in mind, you will be able rest easy knowing you’ve made the best choice for your application.

Selecting the correct flowmeter can be a challenging task, and the variety of flow technology options can make the decision even more difficult. By keeping the benefits and drawbacks of each type in mind, you will be able rest easy knowing you’ve made the best choice for your application.

OEM stands for Original Equipment Manufacturer and describes companies that make devices from component parts. Some OEMs also offer calibration services that are specific to the product you purchased from them. For many types of test equipment, annual calibration is necessary to ensure the measured values meet the original specifications. Sending your equipment back to the original manufacturer ensures the highest-quality calibration, giving you the confidence needed to effectively measure and test in your business.

OEM stands for Original Equipment Manufacturer and describes companies that make devices from component parts. Some OEMs also offer calibration services that are specific to the product you purchased from them. For many types of test equipment, annual calibration is necessary to ensure the measured values meet the original specifications. Sending your equipment back to the original manufacturer ensures the highest-quality calibration, giving you the confidence needed to effectively measure and test in your business.

Dwyer Instruments, Inc. was recognized for excellence in product design in the 16th annual Dealer Design Awards Program sponsored by The Air Conditioning Heating & Refrigeration News Magazine (The ACHR News). An independent panel of contractors acted as judges in the contest that had 79 entries. The company’s Hydronic Application Software was the Silver Award Winner in the Contractor Services & Software product category. The ACHR News is the leading trade magazine in the heating, ventilating, air conditioning, and refrigeration industries.

Dwyer Instruments, Inc. was recognized for excellence in product design in the 16th annual Dealer Design Awards Program sponsored by The Air Conditioning Heating & Refrigeration News Magazine (The ACHR News). An independent panel of contractors acted as judges in the contest that had 79 entries. The company’s Hydronic Application Software was the Silver Award Winner in the Contractor Services & Software product category. The ACHR News is the leading trade magazine in the heating, ventilating, air conditioning, and refrigeration industries.

We recently met with a customer in India who needed to replace a flowmeter in an Energy Monitoring System (EMS) application in a commercial shopping mall.

We recently met with a customer in India who needed to replace a flowmeter in an Energy Monitoring System (EMS) application in a commercial shopping mall.