Open channel flow monitoring is a method of measuring water flow rates in irrigation channels, streams, and storm water systems. It’s also used in wastewater processing for monitoring the effluent discharge. In most applications for open channel flow, weirs and flumes are used. For those of us not familiar, weirs and flumes concentrate the flow into a known cross sectional area, relating an accurate level reading to an accurate flow rate. The height of the water in the channel, going over the weir or flume, is directly proportional to the flow rate. Continue reading “Open Channel Flow Monitoring”

Open channel flow monitoring is a method of measuring water flow rates in irrigation channels, streams, and storm water systems. It’s also used in wastewater processing for monitoring the effluent discharge. In most applications for open channel flow, weirs and flumes are used. For those of us not familiar, weirs and flumes concentrate the flow into a known cross sectional area, relating an accurate level reading to an accurate flow rate. The height of the water in the channel, going over the weir or flume, is directly proportional to the flow rate. Continue reading “Open Channel Flow Monitoring”

Manufacturing an Economic Dust Filtration System

Many customers have come to the Dwyer team asking: “What can Dwyer do to help with lean manufacturing?” In this article, we will discuss the Dwyer® Series SVT solenoid valve and timer enclosure and its cost savings advantages in a dust filtration system.

The Series SVT combines two integral components in a dust filtration system into one package: solenoid valves and a timer controller. In a dust filtration system, solenoid valves are used to send air through a pulse valve, such as our Series RDCS. Pulse valves release a quick spurt of air into a dirty dust cartridge filter, which, in turn, releases the dust from the filter. The timer portion of the dust filtration system is the brains of the operation controlling when the solenoids fire, the amount of time the solenoids are open, and when the next solenoid in the sequence fires. Continue reading “Manufacturing an Economic Dust Filtration System”

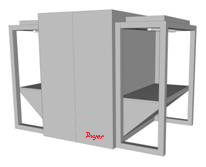

Downdraft Table Applications

There are many manufacturing processes that require human operators to perform tasks, which can create hazardous levels of particulate, fumes, gases, vapors, and mists. A few of these processes include: welding, sanding, grinding, brazing, laser cutting, tempering, and quenching. The Occupational Safety and Health Administration (OSHA) has regulatory requirements to reduce worker’s exposure to these hazards, which can cause respiratory and other health issues. Downdraft tables are workstations designed to better protect the operators who perform these tasks, in a bench top setting, by removing the hazardous material that laden the air from the worker’s breathing zone. Continue reading “Downdraft Table Applications”

What are Room Pressure and Room Status Monitors?

Differential pressure between two rooms prevents dust, particulates, and pathogens from entering or exiting one room and going into the other. Depending on the relationship between rooms, one room will be under positive pressure when referenced against the other. This positive-negative pressure relationship between two spaces is the main idea behind clean rooms and isolation rooms. To ensure the differential pressure relationship is maintained, a measuring device must be used.

Room pressure monitors and room status monitors measure, display, and transmit the differential pressure reading between two rooms. In general, room pressure monitors only monitor differential pressure. On the other hand, room status monitors monitor differential pressure and additional parameters such as relative humidity, temperature, air change, or door status. They are both used in critical applications that require critical low differential pressure relationships. Continue reading “What are Room Pressure and Room Status Monitors?”

Level Detection of Powder & Bulk Solids

Level detection applications are one of the most interesting things we do at Dwyer as there are so many types of switch technologies. Even just for powder and bulk level detection, there are many ways to sense the level. Dwyer offers several different technologies for powder and bulk solids point level detection. These include: diaphragm, paddle, tilt, capacitive, and vibration. So if you’re wondering how to determine which technology is best for your application, here is a simple guide to help you select the proper technology. Continue reading “Level Detection of Powder & Bulk Solids”

Level detection applications are one of the most interesting things we do at Dwyer as there are so many types of switch technologies. Even just for powder and bulk level detection, there are many ways to sense the level. Dwyer offers several different technologies for powder and bulk solids point level detection. These include: diaphragm, paddle, tilt, capacitive, and vibration. So if you’re wondering how to determine which technology is best for your application, here is a simple guide to help you select the proper technology. Continue reading “Level Detection of Powder & Bulk Solids”