The curtain has fallen on two fantastic tradeshows, AHR Expo and World of Concrete, and we’re still buzzing with excitement! We want to extend a heartfelt thank you to all the amazing customers, partners, and teammates who made these events unforgettable. Continue reading “Reflections: AHR Expo, World of Concrete, and What’s Next!”

Precision on Demand: Dwyer’s Online Product Configurator and Fast Track Program

In the dynamic landscape of industrial instrumentation, every application has its unique demands. We want to ensure that our products meet your application needs. To do that, Dwyer Instruments provides not only a user-friendly online product configurator, but also a Fast Track Program for a fully customized solution.

In the dynamic landscape of industrial instrumentation, every application has its unique demands. We want to ensure that our products meet your application needs. To do that, Dwyer Instruments provides not only a user-friendly online product configurator, but also a Fast Track Program for a fully customized solution.

Continue reading “Precision on Demand: Dwyer’s Online Product Configurator and Fast Track Program”

How Thermal Flowmeters Work

Thermal flowmeters use the thermal properties of the fluid to measure the flow of a fluid flowing in a pipe or duct. In a typical thermal flowmeter, a measured amount of heat is applied to the heater of the sensor. Some of this heat is lost to the flowing fluid. As flow increases, more heat is lost. The amount of heat lost is sensed using temperature measurement(s) in the sensor. The transmitter uses the heat input and temperature measurements to determine fluid flow. Most thermal flowmeters are used to measure gas flows. Thermal flowmeters represent 2% of global flowmeter sales. Continue reading “How Thermal Flowmeters Work”

Thermal flowmeters use the thermal properties of the fluid to measure the flow of a fluid flowing in a pipe or duct. In a typical thermal flowmeter, a measured amount of heat is applied to the heater of the sensor. Some of this heat is lost to the flowing fluid. As flow increases, more heat is lost. The amount of heat lost is sensed using temperature measurement(s) in the sensor. The transmitter uses the heat input and temperature measurements to determine fluid flow. Most thermal flowmeters are used to measure gas flows. Thermal flowmeters represent 2% of global flowmeter sales. Continue reading “How Thermal Flowmeters Work”

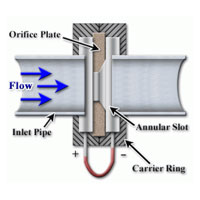

Flow Measurement with Orifice Plates

Dwyer Instruments offers many types of flow measuring products including orifice plates, which are used as a flow sensing element with a differential pressure monitor.

Orifice plates are a primary flow element, detecting the flow of a fluid passing through the plate by sensing the pressure drop across the plate. When a fluid flows through a restriction in a pipe, it creates a pressure difference between upstream and downstream of the restriction. This pressure difference is proportional to flow rate according to Bernoulli’s principal, similar to a Pitot tube. Orifice plates are commonly used as they are simple to use, low cost, work with gases or liquids, and require low maintenance. Adversely, they do have large pressure losses with about 50% of the pressure drop not recoverable. Continue reading “Flow Measurement with Orifice Plates”

How Electromagnetic Flowmeters Work

Electromagnetic flowmeters, also known as magnetic flowmeters or magmeters, use Faraday’s Law of Electromagnetic Induction to determine the flow of liquid in a pipe. In an electromagnetic flowmeter, a magnetic field is generated and channeled into the liquid flowing through the pipe. Following Faraday’s Law, flow of a conductive liquid through the magnetic field will cause a voltage signal to be sensed by electrodes located on the flow tube walls. When the fluid moves faster, more voltage is generated. Faraday’s Law states that the voltage generated is proportional to the movement of the flowing liquid. The electronic transmitter processes the voltage signal to determine liquid flow.

Electromagnetic flowmeters, also known as magnetic flowmeters or magmeters, use Faraday’s Law of Electromagnetic Induction to determine the flow of liquid in a pipe. In an electromagnetic flowmeter, a magnetic field is generated and channeled into the liquid flowing through the pipe. Following Faraday’s Law, flow of a conductive liquid through the magnetic field will cause a voltage signal to be sensed by electrodes located on the flow tube walls. When the fluid moves faster, more voltage is generated. Faraday’s Law states that the voltage generated is proportional to the movement of the flowing liquid. The electronic transmitter processes the voltage signal to determine liquid flow.

In contrast with many other flowmeter technologies, electromagnetic flowmeter technology produces signals that are linear with flow. As such, the turndown associated with magnetic flowmeters can approach 20:1 or better without sacrificing accuracy. Continue reading “How Electromagnetic Flowmeters Work”