We talk a lot on this blog about the importance of indoor air quality in schools to boost students’ well-being. Also important to the school building is ensuring that the building is energy efficient – the dollars saved by reducing energy consumption can be used to further improve school facilities and enhance students’ learning environments. Continue reading “School Energy Monitoring Solutions”

We talk a lot on this blog about the importance of indoor air quality in schools to boost students’ well-being. Also important to the school building is ensuring that the building is energy efficient – the dollars saved by reducing energy consumption can be used to further improve school facilities and enhance students’ learning environments. Continue reading “School Energy Monitoring Solutions”

Gas Mass Measurement

Energy costs are rising around the world. In the United States, the cost of electricity, natural gas, and coal are all expected to increase in 2020.[1] As oil prices increase, energy costs are rising in Britain, and in Australia, the cost of electricity has skyrocketed.[2] It will become increasingly necessary to manage costs by maintaining efficient operation of energy systems as energy prices continue to rise.

Energy costs are rising around the world. In the United States, the cost of electricity, natural gas, and coal are all expected to increase in 2020.[1] As oil prices increase, energy costs are rising in Britain, and in Australia, the cost of electricity has skyrocketed.[2] It will become increasingly necessary to manage costs by maintaining efficient operation of energy systems as energy prices continue to rise.

Steam is a common byproduct of energy generation in boiler systems. When energy is generated in a boiler system, heat energy is transferred to water, which generates steam used for heating. Measuring the steam produced by a boiler is the most logical way to measure boiler output, but it is extremely difficult to measure steam output accurately.[3] In a world where energy costs are only expected to increase, it is imperative that boiler output be measured accurately in order to conserve both money and energy. Continue reading “Gas Mass Measurement”

The Key to Energy Efficiency

“In the real estate industry you always hear this phrase, ‘Location, location, location.’ I think for energy management systems the key is ‘Execution, execution, execution.'”[1]

— Sara Lisauskas, Energy Management Systems: Maximizing Energy Savings

What comes to mind when you think of the phrase “energy efficient?” Perhaps you think of LED light bulbs, electric cars, Energy Star appliances, or LEED-certified buildings. But energy efficiency isn’t limited to “green” products or certifications. Continue reading “The Key to Energy Efficiency”

What comes to mind when you think of the phrase “energy efficient?” Perhaps you think of LED light bulbs, electric cars, Energy Star appliances, or LEED-certified buildings. But energy efficiency isn’t limited to “green” products or certifications. Continue reading “The Key to Energy Efficiency”

Flowmeter Used in an Energy Monitoring System Application

We recently met with a customer in India who needed to replace a flowmeter in an Energy Monitoring System (EMS) application in a commercial shopping mall.

We recently met with a customer in India who needed to replace a flowmeter in an Energy Monitoring System (EMS) application in a commercial shopping mall.

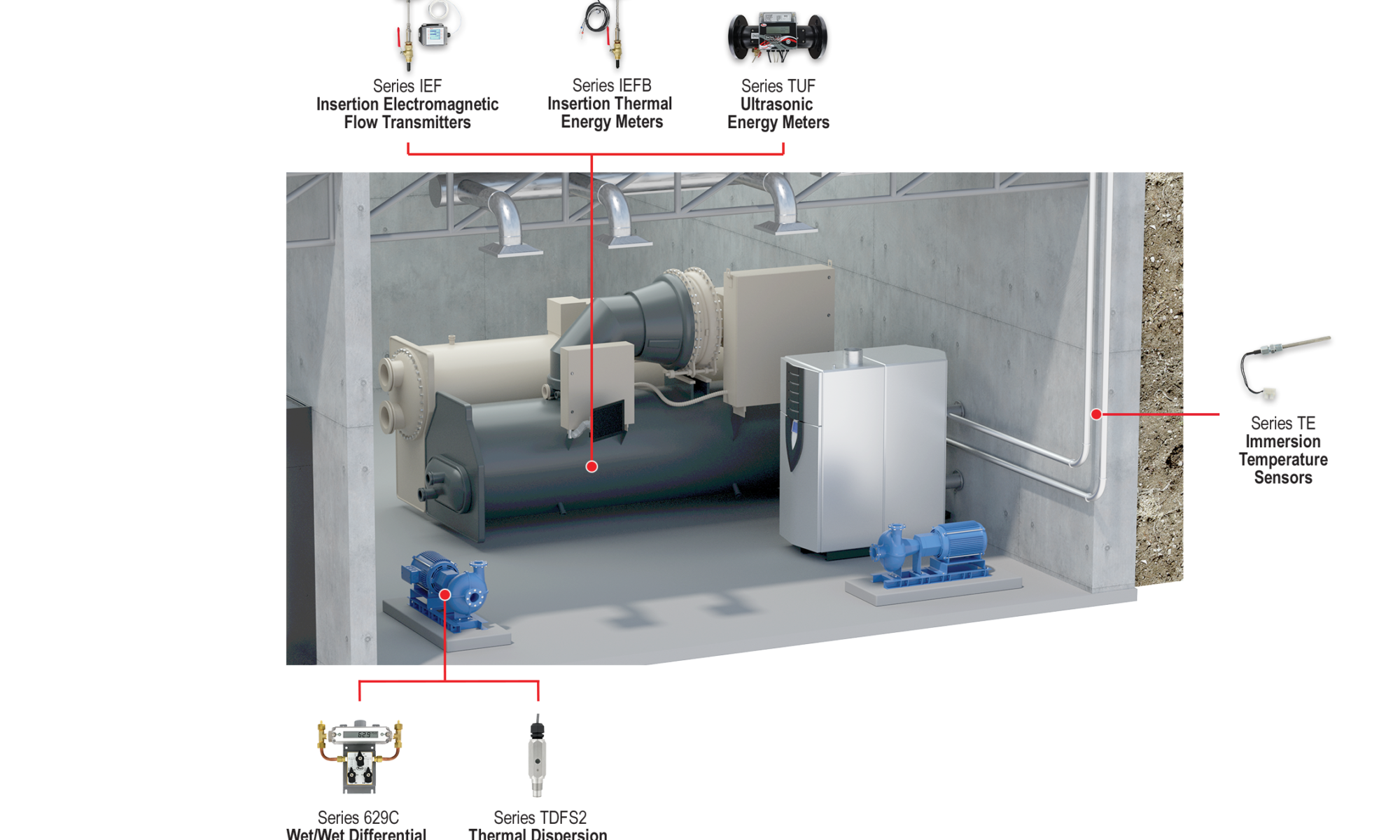

Energy Monitoring Systems (EMS) continuously monitor and record chiller operating data. The EMS utilizes flowmeters installed in each chiller to measure flow. Temperature sensors are located in the inlet and outlet of the evaporators and condensers. A kWh meter measures the power consumption of each chiller. The data from each of these devices is collected and recorded within the control panel, which is then sent to a report generated in the cloud. This kind of system can accurately report the data used to manage energy and operating costs.

Because the space was occupied, the application couldn’t be shut down for maintenance or repairs. This meant that we needed to look into alternative solutions that wouldn’t affect system operations with unnecessary downtime. Continue reading “Flowmeter Used in an Energy Monitoring System Application”