A semiconductor transistor is a part with specific electronic properties that allow it to serve as a component in microchips and modern electronics like phones, laptops, and more. As these components are small and require precise manufacturing methods, there are facilities dedicated to their manufacture.

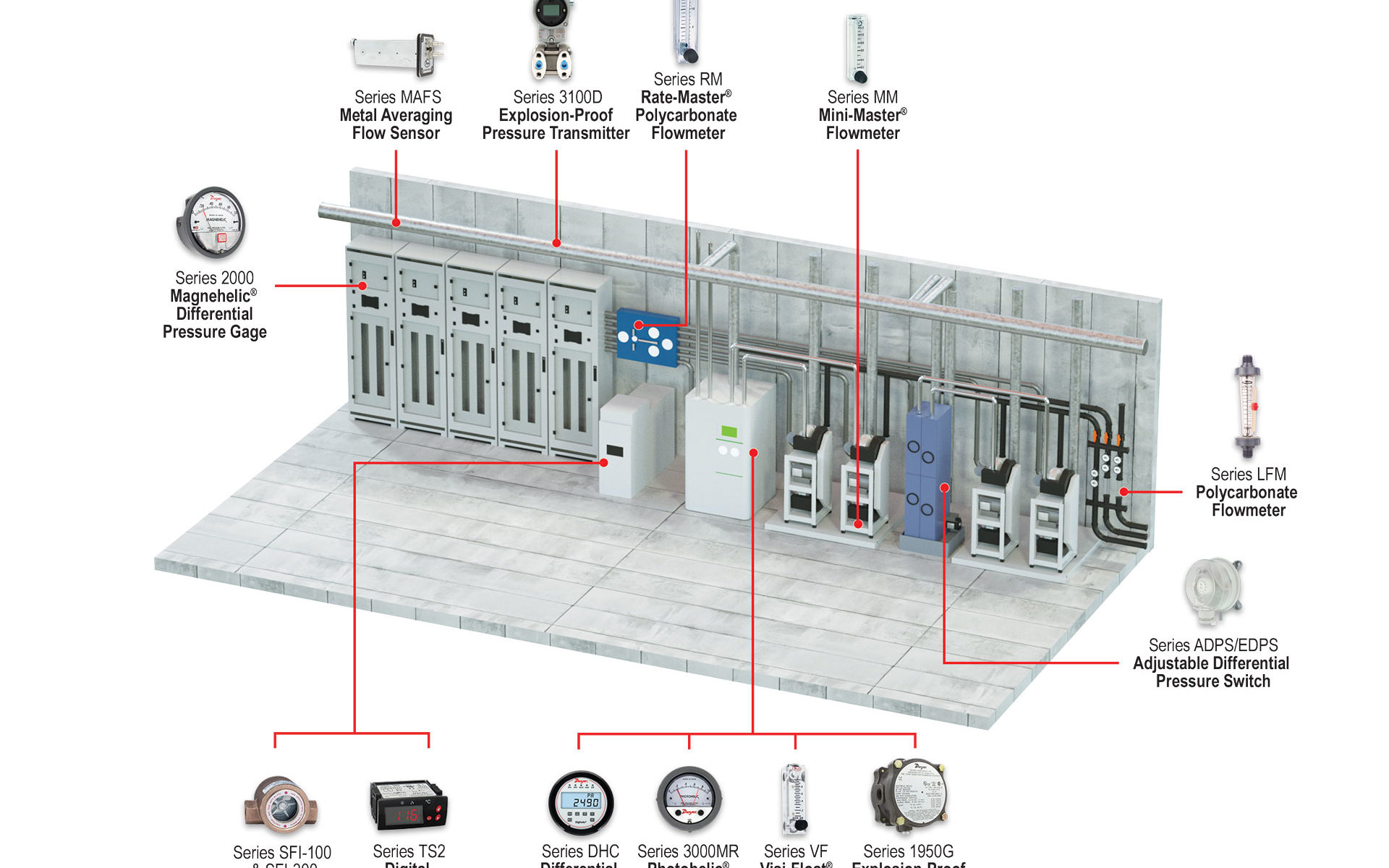

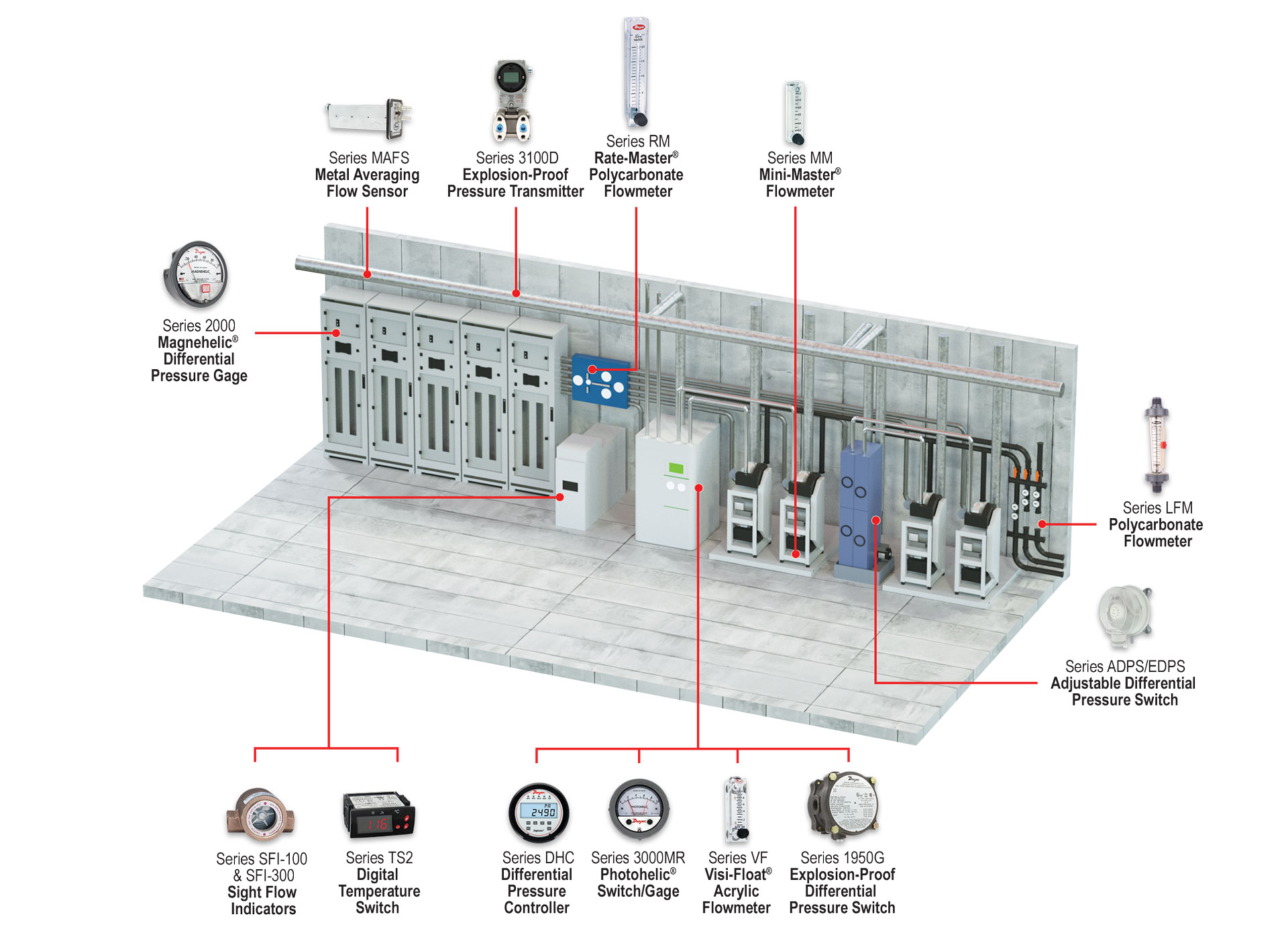

These facilities consist of several levels including air handlers and scrubbers for exhaust, HEPA room, fab cleanroom, and subfab areas. The control of pressure, flow, and temperature within the facility is essential.

Semiconductor subfabs are located directly below the cleanroom. Here you will find an array of ancillary equipment, such as vacuum pumps, abatement systems, chillers, gas cabinets, and other equipment to keep process tools functioning efficiently. The equipment within the subfab is interconnected with the tools found within the fab cleanroom itself; these separate but connected areas work together to make sure the facility runs smoothly. Continue reading “Monitoring Solutions for Semiconductor Subfabs”