Hi-Flow™ Valve Application

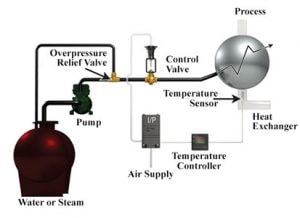

Hi-Flow™ Valve Application Control valves are used to change process conditions such as flow, temperature, level, and pH. A complete control system would include a sensor, controller, positioner or current to pressure transducer, and control valve. Globe valves, such as the DwyerOmega Hi-Flow™ Series, are a common type of control valve. In the example shown, a Hi-Flow™ control valve is controlling temperature by varying the amount of steam or cold water added to the process.

Hi-Flow™ Valve Cutaway

Hi-Flow™ Valve Cutaway All control valves have a rated flow capacity expressed as the Cv rating. The valve flow coefficient (Cv) is the number of US gallons per minute of 60 degree Fahrenheit water that will pass through a fully open valve with a 1 psi pressure drop. For example, a Hi-Flow™ valve with a Cv rating of 10.75 will pass 10.75 gallons per minute of water with a pressure drop of 1 psi across the valve.

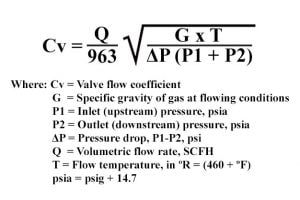

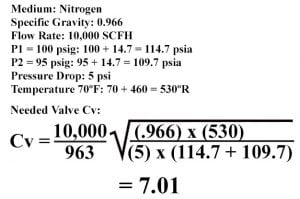

For Gas, use the equation shown with Cv dependent upon upstream pressure, downstream pressure, pressure drop taken, volumetric flow rate needed, temperature, and specific gravity.

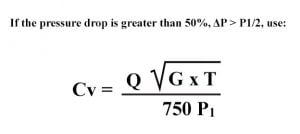

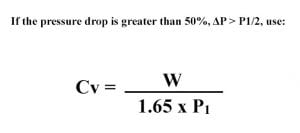

If taking greater than 50% of the upstream pressure for pressure drop, use the shown simplified equation:

Here is an example calculation for a gas application:

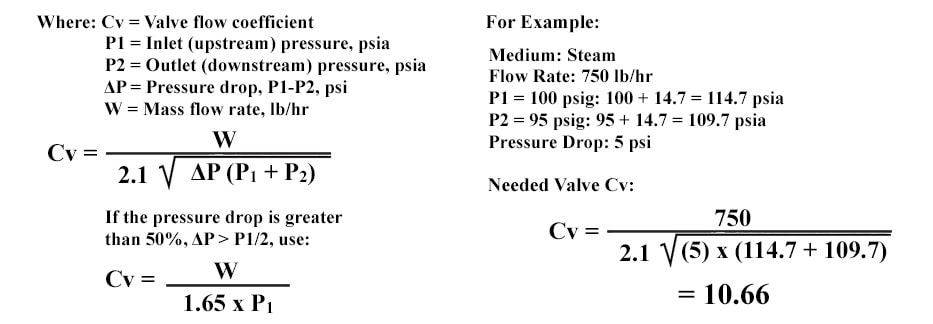

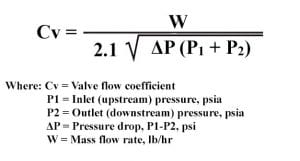

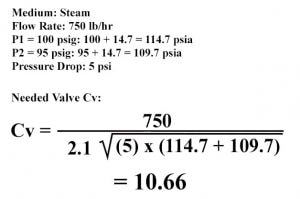

For steam, use the equation shown, with Cv dependent upon upstream pressure, downstream pressure, pressure drop taken, and mass flow rate needed.

If taking greater than 50% of the upstream pressure for pressure drop, use the shown simplified equation:

Here is an example calculation for a steam application:

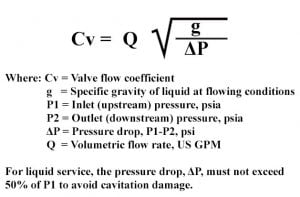

For liquid service, the pressure drop must not exceed 50% of the upstream pressure. Use the equation shown with Cv dependent upon upstream pressure, downstream pressure, pressure drop taken, volumetric flow rate needed, and specific gravity.

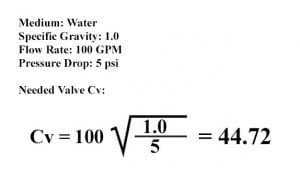

Here is an example calculation for a liquid application:

Once the required Cv is determined, selection of the proper size control valve can be obtained by comparing the calculated application required Cv to the Cv values for the Hi-Flow™ valves. To size properly, it is best to increase the required Cv by 10 to 15% to account for different operating conditions. In addition, the minimum required controllable flow should fall within the rangeability of the valve. The rangeability of Hi-Flow™ valves is 50 to 1. For example, if a Hi-Flow™ valve was chosen with a Cv of 10.75, then the minimum controllable Cv would be 10.75 divided by 50 (a quotient of 0.215). The Cv values for the High Flow™ valves are shown on the DwyerOmega catalog pages and instruction manuals on our website. Shown below are the Cv values for the Hi-Flow™ valves with full ports and linear characteristics.