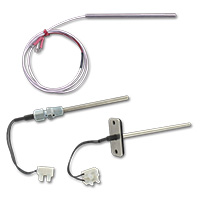

Dwyer Instruments, Inc. offers a wide variety of temperature sensors that use RTDs as the sensing element.

RTDs are based on the principal that the electrical resistance of the wire is a function of the temperature, with the resistance increasing as temperature increases. The resistance varies nearly linearly with temperature per the Callendar Van-Dusen equation. The wire used in RTDs as the sensing element is usually constructed of platinum, copper, or nickel. Platinum is the best material for this element, as it has the widest useful temperature range of these materials. It also has a very repeatable and linear temperature to resistance correlation.

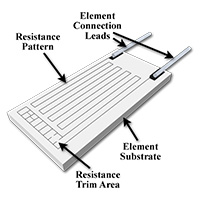

There are three main types of construction of RTDs: thin film, wire-wound, and coiled elements. In thin film, the conductor is deposited as a thin film on a ceramic substrate.

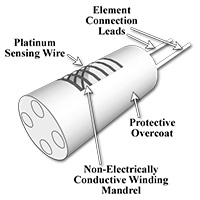

In wire wound, a fine wire is wound around an insulator, typically a glass or ceramic bobbin, with a seal coating of ceramic and glass.

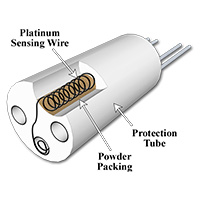

In coiled elements the wire coil can expand freely over temperature. The mandrel is made of an insulator that has holes bored through it for the wire sensing coils. The coils are packed with ceramic powder to hold the coils in place but allow freedom to expand and contract.

RTDs are made to have a specific resistance value at a specific temperature and are designated accordingly. A common type is a platinum 100 ohms, which has a resistance of 100 ohms at 0 degrees Celsius and is designated as a pt100. The temperature coefficient of resistance of the metal can vary in the construction of an RTD, so there are standard coefficients used according to IEC 60751 and ASTM E-1137 to set industry norms.

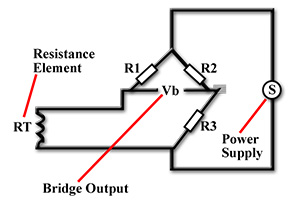

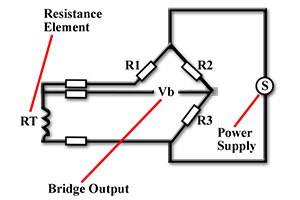

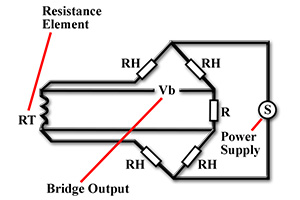

Circuits similar to a Wheatstone bridge are built into controls for use with RTDs. RTDs come in 2, 3, and 4 wire configurations with the more wires generally being more accurate.

The leads to the RTD in a two-wire circuit have a resistance of their own that is not accounted for and can create significant error. A 30 meter lead wire can add 1 to 5 ohms to the circuit. Typically, this type of circuit can be used with up to 100 meters of cable.

Three-wire construction modifies the Wheatstone bridge circuit by adding another lead wire from the RTD, minimizing the effects of the lead resistances. The leads are matched so that resistances are all equal and the resistance in each arm of the bridge balances out. Typically, this type of circuit can be used with up to 600 meters of cable.

Four-wire construction completely eliminates the error due to lead wire resistance and can be used with extended length lead wires.

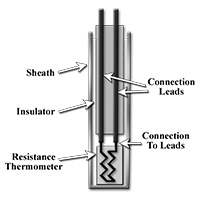

Often RTDs are sheathed in a thin walled stainless tube for protection and for easier insertion into thermowells.

RTDs are wired directly to the measuring instrument or they can be extended with insulated electrical copper wire. Sensor wires should never be run in conduit with power sources because there could be noise problems. Commonly, an RTD is wired into a temperature transmitter when sending the signal a long distance.