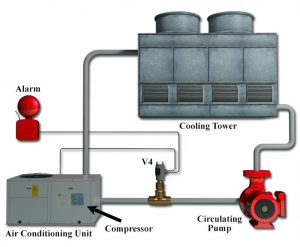

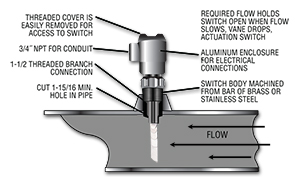

Vane or paddle flow switches are used to initiate high or low flow alarms. A common application is as a low flow alarm for shut-down of a system for protection of the components from damage. Often these are used in cooling lines, oil lines, or monitoring other fluid flows that are critical for the system to operate. In the example shown below, a Flotect® Vane-Operated Flow Switch, Series V4, is used to ensure cooling water circulation before the air conditioning compressor motor starts.

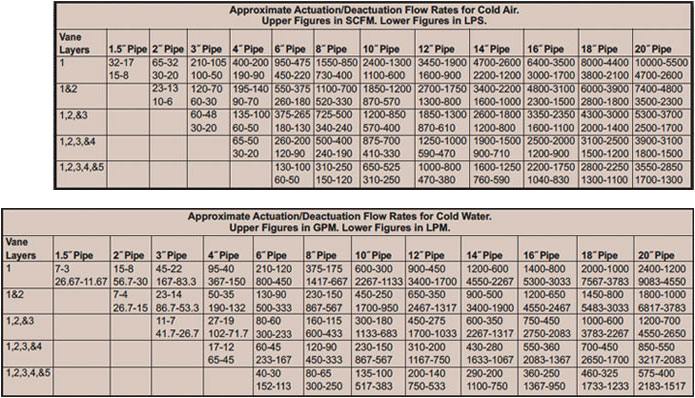

The Flotect® Vane-Operated Flow Switch comes standard with a universal vane that has five adjustable layers for field setting the actuation and deactuation flow set point.

The universal vane works in one and half to 20 inch pipe sizes for fluid or gas applications. Our catalog page and instruction manual show the approximate actuation and deactuation rates according to fluid, pipe size, and vane layer. The actuation point is where the switch changes state on an increase of flow, and the deactuation point is where the switch resets to normal state.

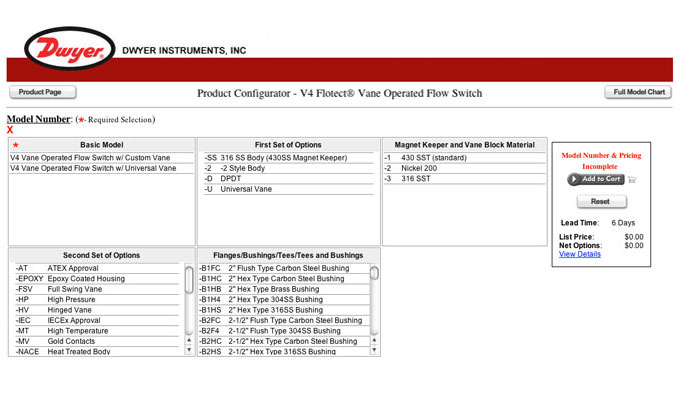

If the universal vane does not have the proper actuation and deactuation point needed for your application, then Dwyer can fabricate a custom vane for your specific application needs, which can usually be made in about two weeks. The custom vane is made with a specific surface area, to actuate or deactuate according to the flow rates you specify. Dwyer can also make it out of a variety of materials according to chemical compatibility needs.

A custom vane model can be ordered by contacting Dwyer technical sales, or directly on our website using the Flotect® Vane-Operated Flow Switch product configurator. Just select the custom vane option and fill in the needed criteria in the pop-up box. You will need to know the pipe size, the fluid and specific gravity, the flow rate unit of measure, the activation flow rate, the deactuation flow rate, which flow rate is critical, the maximum flow rate, and the normal flow rate.

Dwyer will need to know if the actuation or deactuation flow rate is critical based on only being able to ensure that one is met. If it is a low flow alarm, then select the deactuation flow. If it is a high flow alarm, then select the actuation flow. Typically, the deactuation point is approximately 55% of the actuation point for liquids, and 75 to 90% of the actuation point for gases.

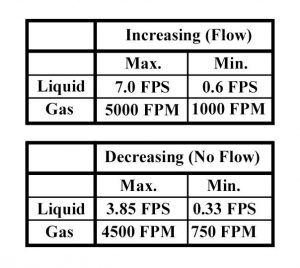

Dwyer can make Flotect® Vane-Operated Flow Switch, Series V4, custom vanes that will actuate on increasing flow in the velocity range of 0.6 to 7 feet per second in liquids and 1000 to 5000 feet per minute in gases. For decreasing flow, in the velocity range of 0.33 to 3.85 feet per second in liquids and 750 to 4500 feet per minute in gases.