Insertion flowmeters provide a great alternative to inline flowmeters because they are typically less expensive and easier to install than inline meters. But how do you know which type of insertion meter to choose?

There are two primary types of insertion flowmeters: mechanical and non-mechanical. It's vital to understand the application and benefits of each type of meter, to ensure the best instrumentation solution for your application.

The primary differentiator between mechanical and non-mechanical flowmeters is the way in which they measure flow.

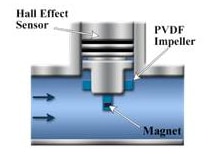

Mechanical insertion flowmeters measure liquid flow rate with a rotor, impeller, or turbine. The function of a mechanical insertion meter is dependent upon the constant movement of that impeller. If the impeller is not rotating correctly, flow cannot be measured accurately; this potentially leads to increased costs or revenue loss. In order to eliminate concerns regarding the function of a mechanical impeller, consider using a non-mechanical insertion magmeter.

Instead of using an impeller, a non-mechanical insertion magmeter calculates flow with an electrode sensor that measures induced voltage and converts it to velocity and flow rate. These flowmeters have minimal maintenance requirements and an increased lifespan, with no moving parts to jam or break.

The application and media (that the meter will come in contact with) are also important considerations.

A mechanical flowmeter is ideal for applications where:

- The media temperature varies

- Diesel, oil, or other magnetic material flow is being monitored, which would not be accurately measured with the electrode of a non-mechanical magmeter

A non-mechanical magmeter is usually better than a mechanical meter when:

- Higher accuracy is required

- The media being measured has debris that could clog an impeller in a mechanical meter

When purchasing an insertion flowmeter, it is also important to consider the up-front cost difference and lifetime cost of ownership. While non-mechanical magmeters tend to have a higher up-front cost than mechanical meters, the non-mechanical option may provide a better return on investment due to eliminating some of the maintenance requirements and extended product lifespan.

For example, if there’s a gap in the bearings around a mechanical flowmeter, the shaft could move, affecting the rotor; this would then affect the accuracy of the flowmeter. If this problem persists, the rotor can break, forcing the purchase of an entirely new meter. The sensor in a non-mechanical magmeter is more likely to maintain accurate readings over time and less likely to fail, because it is not physically moved by the flow of the media.

Dwyer Instruments, Inc. is proud to offer both a mechanical insertion meter and a non-mechanical insertion magmeter. The Paddlewheel Flow Sensor, Series PFT, uses inductive sensing to sense the blades of the impeller for low flow rate monitoring, while the Insertion Electromagnetic Flow Transmitter, Series IEF, features electromagnetic technology that accurately and reliably measures fluid velocity in addition to providing several continuous signal outputs. By keeping the benefits and drawbacks of both types of insertion meters in mind, you will be able to choose the best instrumentation for your application.