Any quick internet search for valves will show many different results: manual or automated, brass or stainless steel, flanged or NPT, one piece, two piece, or three piece, and more. With so many different types of valves available, how can you be sure you are purchasing the right type? While your application will help guide your proper valve selection, it is important to have some basic understanding of the different types of valves offered.

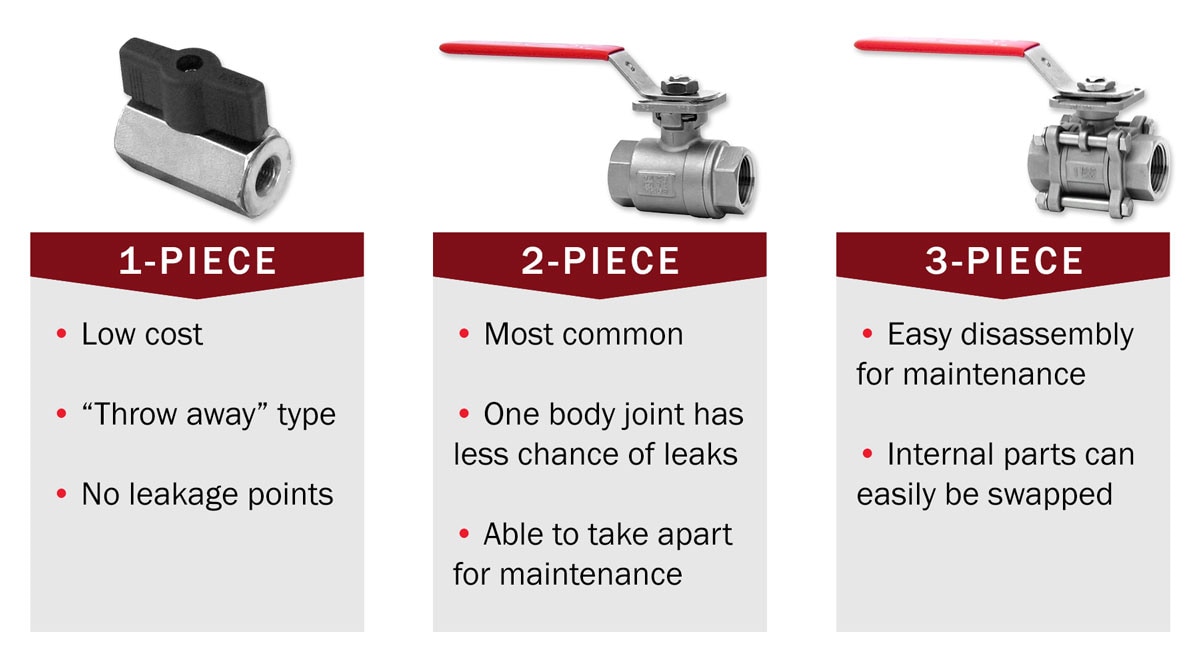

One-piece ball valves have a solid, cast body which reduces the risk for leakage. They are inexpensive and generally not repaired.

Two-piece ball valves are some of the most common ball valves used. As the name suggests, the two piece ball valve consists of two pieces, one piece that has one end connection and the body. The second piece fits into the first, holds the trim in place and includes the second end connection. Once installed these valves typically cannot be repaired unless they are removed from service.

Again, as the name suggests, three-piece ball valves consist of three pieces: two end caps and a body. The end caps are typically threaded or welded to the pipe and the main body section may be easily removed for cleaning or repair without removing the end caps. This can be a very valuable option because it prevents a line shutdown if maintenance is required.

By comparing the features of each valve with your application requirements, you will be able to make an informed decision on which will best suit your needs. Please visit our valves website to learn about our ball valve product line or start configuring today.