We are often asked what size valves are needed for specific applications. To fully answer this question, I will begin by covering some general terminology:

Pressure Drop – The difference in upstream and downstream pressures of the fluid flowing through the valve

Critical Flow – The flow has reached the point of being choked. At the choked condition the flow rate has hit a maximum limit and does not increase with further increase in pressure drop across the valve

Cv or Valve Flow Coefficient – The number of U.S. gallons per minute of water at 60°F that will pass through the valve with a pressure drop of 1 psi. For example, a Hi-Flow™ valve with a maximum Cv of 10.75 has an effective port area in the full open position such that it passes 10.75 GPM of water with a pressure drop of 1 psi

Full Port – The port diameter of the valve is the same diameter as the piping connections

Rangeability – The ratio of maximum controllable flow to minimum controllable flow of a valve. For example, a valve with a 50 to 1 rangeability and a total flow capacity of 100 GPM at full open controls flow accurately to as low as 2 GPM

Valve Flow Characteristic – The relationship between the stem travel or rotation of a valve, expressed in percent travel, and the fluid flow through the valve, expressed in percent of full flow

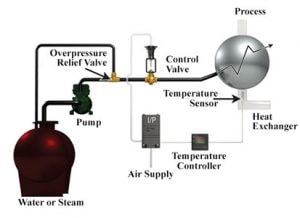

Process Temperature Control Using Pneumatic Hi-Flow™ Control Valves

Process Temperature Control Using Pneumatic Hi-Flow™ Control Valves When sizing valves, we prefer to use the Cv method. The Cv method is an accepted way to size control valves. Basic equations are provided as a guide to use in sizing a control valve, and the results of the equations will only be as accurate as the information provided of the flowing conditions.

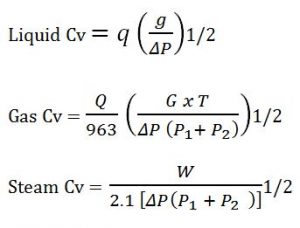

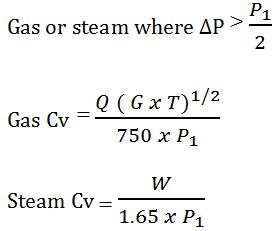

The equations are broken down into the type of media - liquid, gas, or steam, and whether or not the flow is critical. The critical flow equations are to be used for vapor flow when the pressure drop across the valve is greater than half of the upstream pressure. As a general guide to avoid cavitation, do not size a valve for liquid service where the pressure drop is greater than 50% of the upstream pressure.

The equations are as follows:

SUB-CRITICAL FLOW

CRITICAL FLOW

NOMENCLATURE

Cv = Valve flow coefficient

g = Specific gravity of liquid at flowing conditions

G = Specific gravity of gas at flowing conditions

P1 = Upstream pressure, psia

P2 = Downstream pressure, psia

ΔP = Actual pressure drop (P1-P2), psi

q = Liquid volumetric flow rate, U.S. GPM

Q = Gas volumetric flow rate, SCFH

W = Steam weight (mass) flow rate, LB/HR

T = Flowing Temperature, °R (460 + °F)

Once the required Cv is determined, selection of the proper size control valve can be obtained by comparing the required Cv to the Cv values for the valve. As a general rule, the maximum capacity of a control valve should be 15-50% above the maximum process flow, and the minimum required Cv must be within the available rangeability of the valve for proper control. If only the maximum process flow rate was used to calculate Cv, then the percent travel of the valve should be checked and should fall in the range of 65-80% of total travel.

For more information about valve sizing, please watch the informational video below.