In the past few years, oil production in the United States has skyrocketed. In fact, the U.S. is out-producing many OPEC countries and is currently on track to become one of the largest oil-producing countries in the world, alongside Russia and Saudi Arabia.[1] The top oil producing region in the U.S. is known as the Permian Basin, which includes parts of Texas and New Mexico. Other major oil-producing states include Colorado, Oklahoma, North Dakota, Alaska, and California.[2] Continue reading “Hydraulic Fracturing for Oil Extraction”

In the past few years, oil production in the United States has skyrocketed. In fact, the U.S. is out-producing many OPEC countries and is currently on track to become one of the largest oil-producing countries in the world, alongside Russia and Saudi Arabia.[1] The top oil producing region in the U.S. is known as the Permian Basin, which includes parts of Texas and New Mexico. Other major oil-producing states include Colorado, Oklahoma, North Dakota, Alaska, and California.[2] Continue reading “Hydraulic Fracturing for Oil Extraction”

Pressure Monitoring in Pump Systems

Why do the inlet and outlet pressure of pumps need to be monitored? What issues may be encountered if they are not monitored?

Air compressors, irrigation systems, and heat exchangers all use pumps to push air or water through their systems. If the pressure in any of these systems is too high or too low, it could have serious consequences for the pump, the pipes, or the entire system. Most engineers choose pumps that operate 80-110% of their Best Efficiency Point (BEP), the point on the curve where the pump is most efficient. Pump performance will suffer if the pump is operating outside of the BEP, so it is important to monitor pressure to ensure you are getting the most out of your pumping system. Continue reading “Pressure Monitoring in Pump Systems”

Air compressors, irrigation systems, and heat exchangers all use pumps to push air or water through their systems. If the pressure in any of these systems is too high or too low, it could have serious consequences for the pump, the pipes, or the entire system. Most engineers choose pumps that operate 80-110% of their Best Efficiency Point (BEP), the point on the curve where the pump is most efficient. Pump performance will suffer if the pump is operating outside of the BEP, so it is important to monitor pressure to ensure you are getting the most out of your pumping system. Continue reading “Pressure Monitoring in Pump Systems”

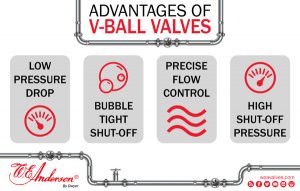

Advantages of V-Ball Valves

Introduction

Ball valves are designed to be used in a variety of applications and markets, but a V-port ball valve offers the added ability to be used as a control valve where necessary. The main differentiator is a contoured V-port in the ball, most commonly available with a 15°, 30°, 45°, 60°, or 90° angle, which produces an equal percentage flow characteristic for better control. V-ball valves are known to offer a variety of advantages in flow control applications, especially when compared to larger and more expensive control valves. Continue reading “Advantages of V-Ball Valves”

Ball valves are designed to be used in a variety of applications and markets, but a V-port ball valve offers the added ability to be used as a control valve where necessary. The main differentiator is a contoured V-port in the ball, most commonly available with a 15°, 30°, 45°, 60°, or 90° angle, which produces an equal percentage flow characteristic for better control. V-ball valves are known to offer a variety of advantages in flow control applications, especially when compared to larger and more expensive control valves. Continue reading “Advantages of V-Ball Valves”

Mechanical vs. Non-Mechanical Flowmeters

Insertion flowmeters provide a great alternative to inline flowmeters because they are typically less expensive and easier to install than inline meters. But how do you know which type of insertion meter to choose?

Insertion flowmeters provide a great alternative to inline flowmeters because they are typically less expensive and easier to install than inline meters. But how do you know which type of insertion meter to choose?

There are two primary types of insertion flowmeters: mechanical and non-mechanical. It’s vital to understand the application and benefits of each type of meter, to ensure the best instrumentation solution for your application. Continue reading “Mechanical vs. Non-Mechanical Flowmeters”

Air Velocity and Flow Measurement with Pitot Tubes

Dwyer offers many styles of Pitot tubes. Pitot tubes are commonly used sensors for monitoring air velocity and flow rate in heating, ventilation, and air conditioning. Some examples include the: Stainless Steel Pitot Tube Series 160, Telescoping Stainless Steel Pitot Tube Series 166T, and “S” Type Stainless Steel Pitot Tube Series 160S.

Pitot tubes are based on Bernoulli’s equation, which states that an increase in the speed of a fluid occurs simultaneously with an increase in dynamic pressure and a decrease in static pressure. Pitot tubes sense the dynamic pressure of the fluid flow at a particular point and were invented by French Engineer Henri Pitot in the early 18th century. Continue reading “Air Velocity and Flow Measurement with Pitot Tubes”