Grain bin systems are the cornerstone of modern agricultural storage, offering a secure and efficient solution for managing harvested grain. Among the critical components of these systems, conveyor systems play a pivotal role in ensuring the smooth movement of grain within the bins. In this article, we will delve into the workings of various conveyor systems used with grain bins, providing insights into their functionality. Additionally, we will explore how Dwyer Instruments’ innovative products can enhance the monitoring and control of these conveyor systems. Continue reading “Optimizing Grain Bin Systems: A Comprehensive Guide to Conveyor Systems and Dwyer Instruments”

Grain bin systems are the cornerstone of modern agricultural storage, offering a secure and efficient solution for managing harvested grain. Among the critical components of these systems, conveyor systems play a pivotal role in ensuring the smooth movement of grain within the bins. In this article, we will delve into the workings of various conveyor systems used with grain bins, providing insights into their functionality. Additionally, we will explore how Dwyer Instruments’ innovative products can enhance the monitoring and control of these conveyor systems. Continue reading “Optimizing Grain Bin Systems: A Comprehensive Guide to Conveyor Systems and Dwyer Instruments”

Mitigating Methane in Landfills

In the ongoing narrative of environmental conservation, few adversaries are as concerning as methane gas emissions from landfills. This potent greenhouse gas poses a substantial threat to both our climate and community health, demanding immediate attention and sustainable solutions.

In the ongoing narrative of environmental conservation, few adversaries are as concerning as methane gas emissions from landfills. This potent greenhouse gas poses a substantial threat to both our climate and community health, demanding immediate attention and sustainable solutions.

Landfills contain several different gases and volatile organic compounds (VOCs) caused by the breakdown of waste, with methane and carbon dioxide making up over 90% of them (health.ny.gov). Once waste breaks down and forms landfill gas and particulates, it can potentially spread to nearby buildings or structures through openings like cracks, windows, or ventilation systems and settle in areas of poor ventilation like basements or crawl spaces (health.ny.gov). Continue reading “Mitigating Methane in Landfills”

Navigating Health and Comfort in Airports

In the expansive world of modern travel, airports serve as dynamic hubs connecting people across the globe. However, amid the seamless connectivity and operational efficiency, there exists a nuanced concern—the potential health implications associated with prolonged stays in these bustling environments. From temporary discomforts to potential long-term health risks, both passengers and airport employees may encounter various challenges unique to airport spaces.

In the expansive world of modern travel, airports serve as dynamic hubs connecting people across the globe. However, amid the seamless connectivity and operational efficiency, there exists a nuanced concern—the potential health implications associated with prolonged stays in these bustling environments. From temporary discomforts to potential long-term health risks, both passengers and airport employees may encounter various challenges unique to airport spaces.

Although the COVID-19 pandemic brought concerns about the impact of the built environment on health out of the proverbial “back room,” experts have been mulling over solutions to these problems for decades. Airports are of particularly high concern as they act as something of a mini city. Jet fuel, exhaust, and other chemicals have a large environmental impact on the outdoor air quality, while carbon dioxide and volatile organic compounds (VOCs), like formaldehyde, can greatly impact the health and indoor air quality (IAQ) of airport occupants. Continue reading “Navigating Health and Comfort in Airports”

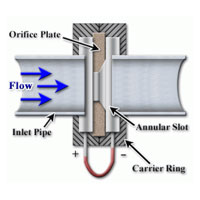

Flow Measurement with Orifice Plates

Dwyer Instruments offers many types of flow measuring products including orifice plates, which are used as a flow sensing element with a differential pressure monitor.

Orifice plates are a primary flow element, detecting the flow of a fluid passing through the plate by sensing the pressure drop across the plate. When a fluid flows through a restriction in a pipe, it creates a pressure difference between upstream and downstream of the restriction. This pressure difference is proportional to flow rate according to Bernoulli’s principal, similar to a Pitot tube. Orifice plates are commonly used as they are simple to use, low cost, work with gases or liquids, and require low maintenance. Adversely, they do have large pressure losses with about 50% of the pressure drop not recoverable. Continue reading “Flow Measurement with Orifice Plates”

Semiconductor Tool Parameter Monitoring Solutions

A semiconductor transistor is a part with specific electronic properties that allow it to serve as a component in microchips and modern electronics like phones, laptops, and more. As these components are small and require precise manufacturing methods, there are facilities dedicated to their manufacture.

These facilities consist of several levels including air handlers and scrubbers for exhaust, HEPA room, fab cleanroom, and subfab areas. The control of pressure, flow, and temperature within the facility is essential.

![]()

Semiconductor process tools are used for the production of microchips and other microelectronic components. These process tools are highly engineered and have a multitude of applications such as pneumatics, electrical, electronics, fume exhaust, chemical & gas distribution, radio frequency (RF) generation, and ultra-high vacuum. Dwyer products help to ensure that process tools are being monitored and controlled to the system owner’s designated parameters. Continue reading “Semiconductor Tool Parameter Monitoring Solutions”