Thermal flowmeters use the thermal properties of the fluid to measure the flow of a fluid flowing in a pipe or duct. In a typical thermal flowmeter, a measured amount of heat is applied to the heater of the sensor. Some of this heat is lost to the flowing fluid. As flow increases, more heat is lost. The amount of heat lost is sensed using temperature measurement(s) in the sensor. The transmitter uses the heat input and temperature measurements to determine fluid flow. Most thermal flowmeters are used to measure gas flows. Thermal flowmeters represent 2% of global flowmeter sales. Continue reading “How Thermal Flowmeters Work”

Thermal flowmeters use the thermal properties of the fluid to measure the flow of a fluid flowing in a pipe or duct. In a typical thermal flowmeter, a measured amount of heat is applied to the heater of the sensor. Some of this heat is lost to the flowing fluid. As flow increases, more heat is lost. The amount of heat lost is sensed using temperature measurement(s) in the sensor. The transmitter uses the heat input and temperature measurements to determine fluid flow. Most thermal flowmeters are used to measure gas flows. Thermal flowmeters represent 2% of global flowmeter sales. Continue reading “How Thermal Flowmeters Work”

How Ultrasonic Flowmeters Work

Ultrasonic flowmeters use sound waves to determine the velocity of a fluid flowing in a pipe. At no flow conditions, the frequencies of an ultrasonic wave transmitted into a pipe and its reflections from the fluid are the same. Under flowing conditions, the frequency of the reflected wave is different due to the Doppler effect. When the fluid moves faster, the frequency shift increases linearly. The transmitter processes signals from the transmitted wave and its reflections to determine the flow rate. Continue reading “How Ultrasonic Flowmeters Work”

Ultrasonic flowmeters use sound waves to determine the velocity of a fluid flowing in a pipe. At no flow conditions, the frequencies of an ultrasonic wave transmitted into a pipe and its reflections from the fluid are the same. Under flowing conditions, the frequency of the reflected wave is different due to the Doppler effect. When the fluid moves faster, the frequency shift increases linearly. The transmitter processes signals from the transmitted wave and its reflections to determine the flow rate. Continue reading “How Ultrasonic Flowmeters Work”

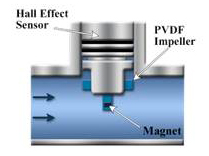

How Paddlewheel Flowmeters Work

Paddlewheel flowmeters use the mechanical energy of the fluid to rotate a paddlewheel (just like a riverboat) in the flow stream. Paddles on the rotor are inserted into the flow to transform energy from the flow stream into rotational energy. The rotor shaft spins on bearings. When the fluid moves faster, the paddlewheel spins proportionally faster. Shaft rotation can be sensed mechanically or by detecting the movement of the paddles.

Paddle movement is often detected magnetically, with each paddle or embedded piece of metal generating a pulse. When the fluid moves faster, more pulses are generated. The transmitter processes the pulse signal to determine the flow of the fluid. Continue reading “How Paddlewheel Flowmeters Work”

Paddle movement is often detected magnetically, with each paddle or embedded piece of metal generating a pulse. When the fluid moves faster, more pulses are generated. The transmitter processes the pulse signal to determine the flow of the fluid. Continue reading “How Paddlewheel Flowmeters Work”

Open Channel Flow Monitoring

Open channel flow monitoring is a method of measuring water flow rates in irrigation channels, streams, and storm water systems. It’s also used in wastewater processing for monitoring the effluent discharge. In most applications for open channel flow, weirs and flumes are used. For those of us not familiar, weirs and flumes concentrate the flow into a known cross sectional area, relating an accurate level reading to an accurate flow rate. The height of the water in the channel, going over the weir or flume, is directly proportional to the flow rate. Continue reading “Open Channel Flow Monitoring”

Open channel flow monitoring is a method of measuring water flow rates in irrigation channels, streams, and storm water systems. It’s also used in wastewater processing for monitoring the effluent discharge. In most applications for open channel flow, weirs and flumes are used. For those of us not familiar, weirs and flumes concentrate the flow into a known cross sectional area, relating an accurate level reading to an accurate flow rate. The height of the water in the channel, going over the weir or flume, is directly proportional to the flow rate. Continue reading “Open Channel Flow Monitoring”

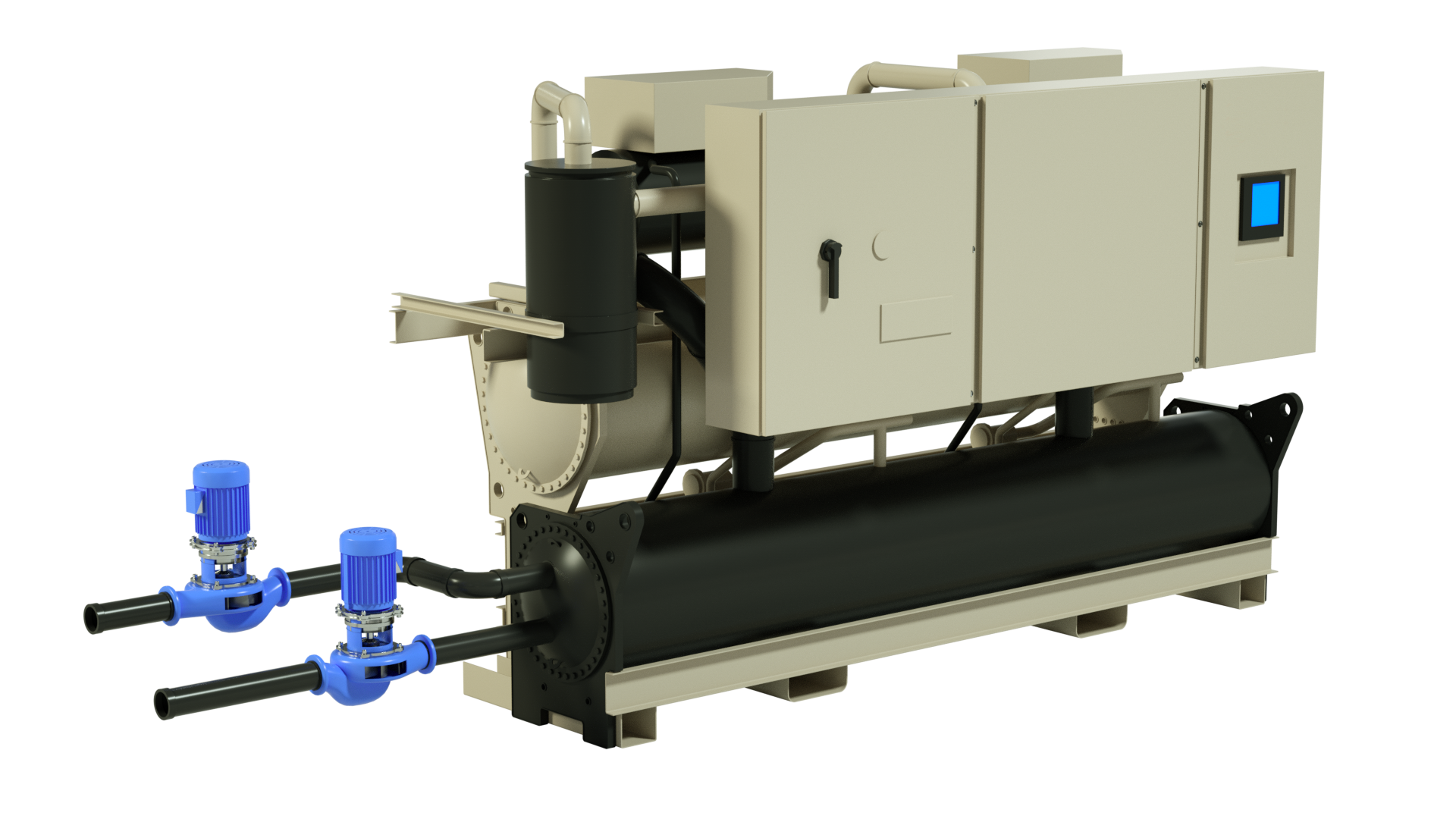

Proving Flow Through Chillers

Water chillers are nothing new, with nearly an estimated 100,000 units operating in North America alone. Chillers are the cooling machines of choice to condition industrial, commercial, and institutional facilities. They are used to lower the temperatures of all kinds of equipment and processes such as: robotic machinery; semiconductors; injection and blow molding machines; welding equipment; die-casting and machine tooling; paper and cement processing; power supplies; power generation stations; compressed air and gas cooling systems; medical imaging machines; chemical, drug, food and beverage production; even simply to cool potable water to desirable levels. Whether for office comfort, keeping data server centers from overheating, or specialized industrial processes, water temperature control plays a vital role in many of the behind-the-scenes activities that affect our everyday lives. Continue reading “Proving Flow Through Chillers”

Water chillers are nothing new, with nearly an estimated 100,000 units operating in North America alone. Chillers are the cooling machines of choice to condition industrial, commercial, and institutional facilities. They are used to lower the temperatures of all kinds of equipment and processes such as: robotic machinery; semiconductors; injection and blow molding machines; welding equipment; die-casting and machine tooling; paper and cement processing; power supplies; power generation stations; compressed air and gas cooling systems; medical imaging machines; chemical, drug, food and beverage production; even simply to cool potable water to desirable levels. Whether for office comfort, keeping data server centers from overheating, or specialized industrial processes, water temperature control plays a vital role in many of the behind-the-scenes activities that affect our everyday lives. Continue reading “Proving Flow Through Chillers”