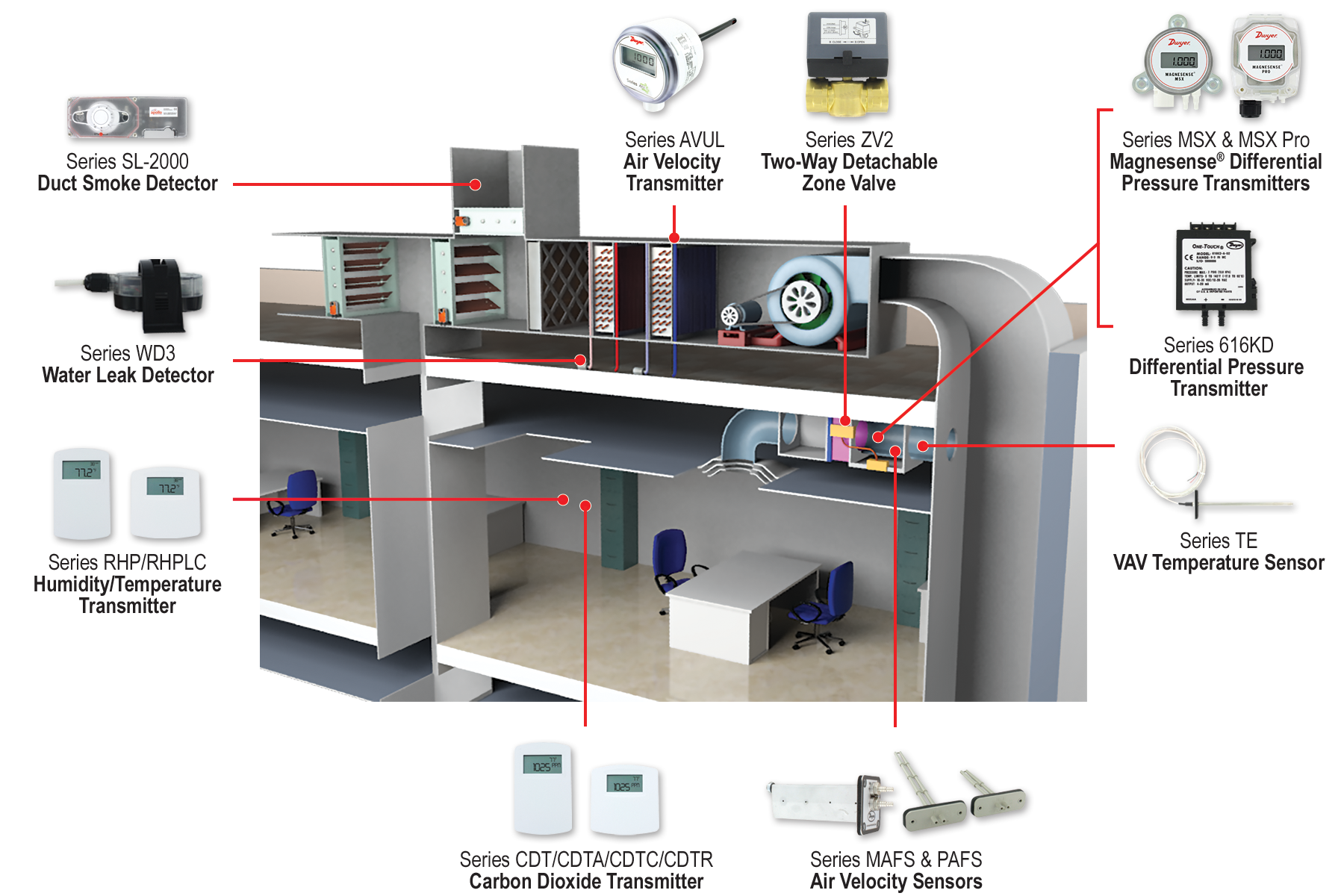

Picture this: you walk into an office building on a hot summer day. As the door closes behind you, you immediately feel the temperature change. It’s cool and refreshing, thanks to the terminal units working diligently behind the scenes. Terminal units, while often unseen and unheard, play a crucial role in maintaining a comfortable environment in various buildings, from offices to schools and hospitals. Let’s explore these components, the challenges they address, and how Dwyer’s range of products helps conquer these challenges.

Picture this: you walk into an office building on a hot summer day. As the door closes behind you, you immediately feel the temperature change. It’s cool and refreshing, thanks to the terminal units working diligently behind the scenes. Terminal units, while often unseen and unheard, play a crucial role in maintaining a comfortable environment in various buildings, from offices to schools and hospitals. Let’s explore these components, the challenges they address, and how Dwyer’s range of products helps conquer these challenges.

Continue reading “Exploring Terminal Units: Dwyer’s Solutions for Better Indoor Environments and Optimal Performance”

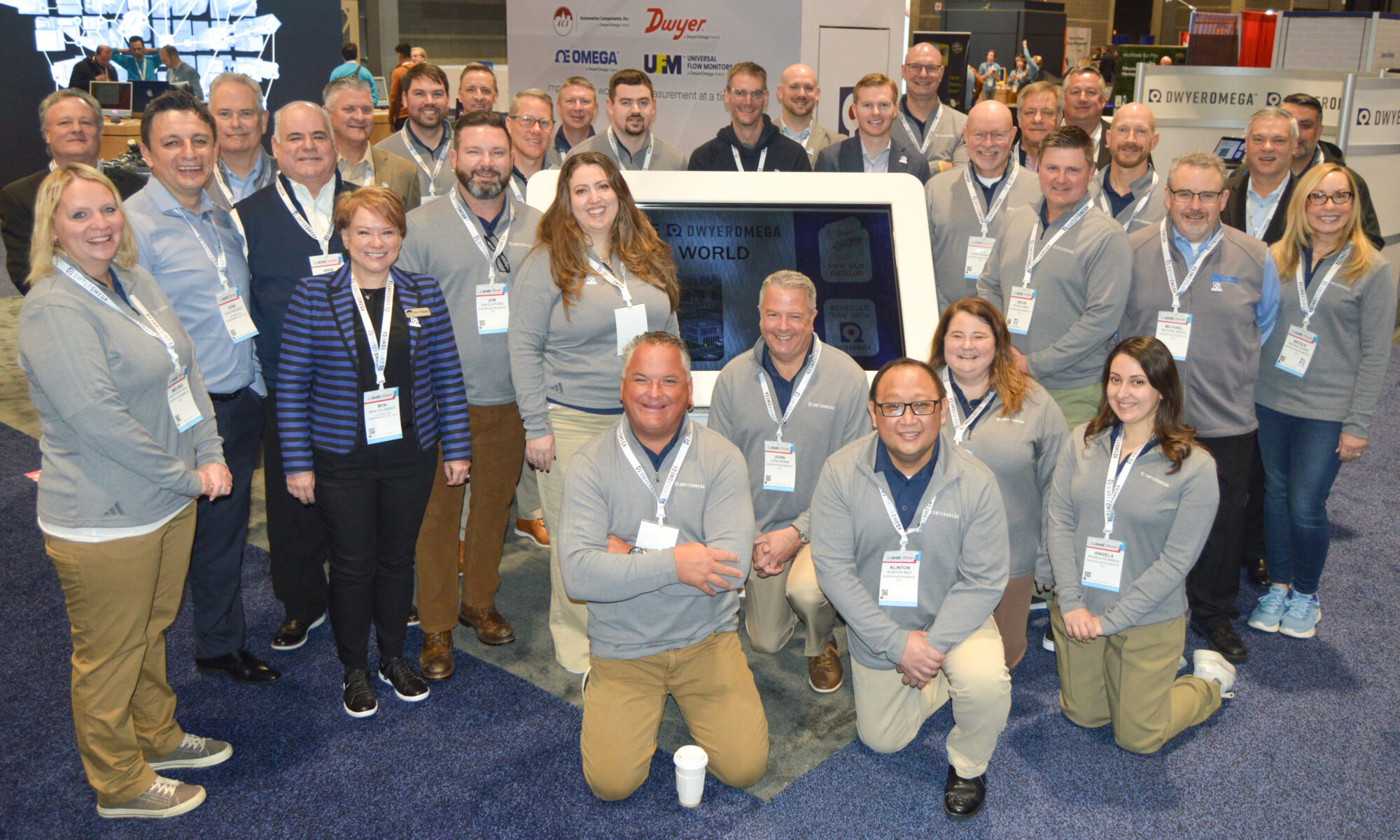

Reflections: AHR Expo, World of Concrete, and What’s Next!

The curtain has fallen on two fantastic tradeshows, AHR Expo and World of Concrete, and we’re still buzzing with excitement! We want to extend a heartfelt thank you to all the amazing customers, partners, and teammates who made these events unforgettable. Continue reading “Reflections: AHR Expo, World of Concrete, and What’s Next!”

Upcoming Tradeshows: Innovation at AHR Expo and World of Concrete

As the new year unfolds, Dwyer Instruments is gearing up to showcase its innovative solutions at two prominent tradeshows in January: AHR Expo and World of Concrete. These events provide a unique platform for professionals and enthusiasts to explore Dwyer’s latest offerings and engage in discussions about industry advancements.

Continue reading “Upcoming Tradeshows: Innovation at AHR Expo and World of Concrete”

Reflecting on a Remarkable Year: 2023 in Review

As the year comes to a close, we find ourselves reflecting on the incredible journey we’ve undertaken at Dwyer Instruments. 2023 has been a year filled with growth, collaboration, and exciting developments, and we couldn’t be more grateful for the opportunities it brought.

As the year comes to a close, we find ourselves reflecting on the incredible journey we’ve undertaken at Dwyer Instruments. 2023 has been a year filled with growth, collaboration, and exciting developments, and we couldn’t be more grateful for the opportunities it brought.

One of the highlights of the year has been the forging of new partnerships. We are thrilled to announce our collaboration with Automation Components, Inc. (ACI), a step that aligns perfectly with our commitment to excellence in the instrumentation industry. The synergy between our teams promises innovative solutions and enhanced offerings for our valued customers. Continue reading “Reflecting on a Remarkable Year: 2023 in Review”

On the Job with Dwyer: Series 490W Wireless Hydronic Differential Pressure Manometer

Dwyer’s Series 490W Wireless Hydronic Differential Pressure Manometer is the most accurate and easy-to-operate manometer on the market. Along with wireless transducers and a mobile device, a single operator using a 490W can monitor and balance a hydronic system in less time and with less manpower than would be possible using a traditional hydronic balancer. In addition, being wireless, the 490W has zero hoses or manifolds – meaning there are no annoying attachments that need to be carried, that can snag onto equipment, or that need to be drained between readings. Continue reading “On the Job with Dwyer: Series 490W Wireless Hydronic Differential Pressure Manometer”