There are several different component parts that go into a dust collector for monitoring and control purposes. In this article, we are going to focus on timer boards. We will be comparing and contrasting a few of our timer boards, as well as discussing how we could help you to better protect your equipment in the most cost-effective manner. Continue reading “Dust Collector Timer Controllers”

There are several different component parts that go into a dust collector for monitoring and control purposes. In this article, we are going to focus on timer boards. We will be comparing and contrasting a few of our timer boards, as well as discussing how we could help you to better protect your equipment in the most cost-effective manner. Continue reading “Dust Collector Timer Controllers”

Level Detection of Powder & Bulk Solids

Level detection applications are one of the most interesting things we do at Dwyer as there are so many types of switch technologies. Even just for powder and bulk level detection, there are many ways to sense the level. Dwyer offers several different technologies for powder and bulk solids point level detection. These include: diaphragm, paddle, tilt, capacitive, and vibration. So if you’re wondering how to determine which technology is best for your application, here is a simple guide to help you select the proper technology. Continue reading “Level Detection of Powder & Bulk Solids”

Level detection applications are one of the most interesting things we do at Dwyer as there are so many types of switch technologies. Even just for powder and bulk level detection, there are many ways to sense the level. Dwyer offers several different technologies for powder and bulk solids point level detection. These include: diaphragm, paddle, tilt, capacitive, and vibration. So if you’re wondering how to determine which technology is best for your application, here is a simple guide to help you select the proper technology. Continue reading “Level Detection of Powder & Bulk Solids”

Pressure Transmitters: Increasing Efficiency and Safety

As industries such as building automation and water/wastewater become more energy-efficient, powder and bulk is also increasing energy efficiency using pressure transmitters and variable frequency drives. Pressure transmitter demand is also growing due to more stringent regulations in hazardous environments, where remote control and specialty housings must be available.

As industries such as building automation and water/wastewater become more energy-efficient, powder and bulk is also increasing energy efficiency using pressure transmitters and variable frequency drives. Pressure transmitter demand is also growing due to more stringent regulations in hazardous environments, where remote control and specialty housings must be available.

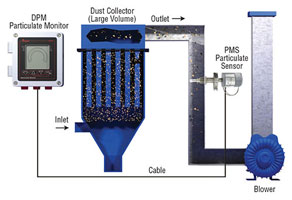

With a typical dust collection system, a pressure sensor (such as our Series A3000 or Series DHII) can measure differential pressure across filter bags. The sensor then sends a switched signal to a timer board (such as the Series DCT500A or DCT1000) to signal a filter cleaning. Pressure in the system is created by a blower, typically positioned near the filter banks on top of the hopper. The system can also use a level switch (like our Series PLS and Series CLS2) to signal a full hopper and possibly open a valve to empty the hopper. So how do pressure transmitters reduce energy consumption? And how can you prevent an explosion in a hazardous environment without the additional cost of specialty enclosures? Continue reading “Pressure Transmitters: Increasing Efficiency and Safety”

Dust Collector Timer Controllers

There are several different component parts that go into a dust collector for monitoring and control purposes. In this article, we are going to focus on timer boards. We will be comparing and contrasting a few of our timer boards, as well as discussing how we could help you to better protect your equipment in the most cost-effective manner. Continue reading “Dust Collector Timer Controllers”

There are several different component parts that go into a dust collector for monitoring and control purposes. In this article, we are going to focus on timer boards. We will be comparing and contrasting a few of our timer boards, as well as discussing how we could help you to better protect your equipment in the most cost-effective manner. Continue reading “Dust Collector Timer Controllers”

Maintain Continuous Operation from Leaking Pulse-Jet Bag Filters

Dust Collector

Dust Collector

A dust collector is a system used to improve the quality of air within an industrial and commercial environment by collecting dust and other impurities from the air. Continue reading “Maintain Continuous Operation from Leaking Pulse-Jet Bag Filters”