Dust Collector

Dust Collector

A dust collector is a system used to improve the quality of air within an industrial and commercial environment by collecting dust and other impurities from the air.

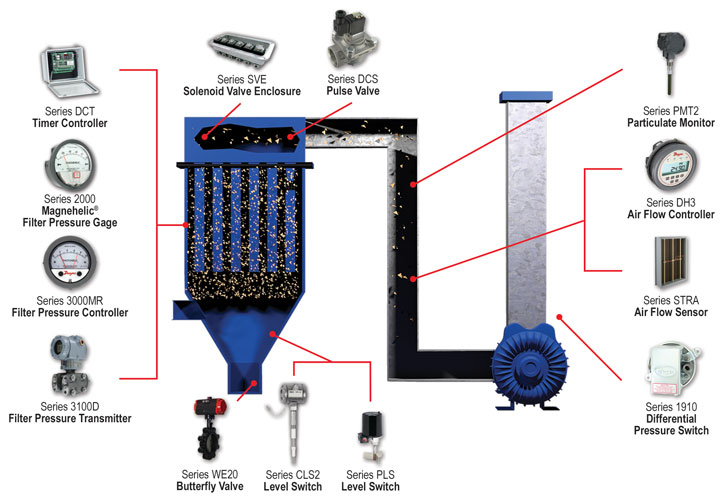

Pulse-Jet Bag Filter Dust Collector

A pulse-jet bag filter dust collector is a dust collection system where bag filters are generally used. These dust collection applications typically require high yield recoveries from a pneumatic transport system or the removal of hazardous materials from an environment.

The pulse-jet bag filter system is designed with a series of modular components. This type of system has a flexible selection of different sizes, materials of construction, filter media, and equipment arrangements.

As the dust filled air enters the dust collector housing through the inlet, the baffle plate directs the heavier dust particles into the hopper for collection. The remaining lighter dust particles are drawn into the filter bags, where they are collected. Clean air then passes through the filter to a clean air plenum leaving through an outlet duct.

Over time the dust accumulates on the filter, so periodic cleaning is important to maintain continuous operation. Periodic cleaning of bags is achieved by a timed, short pulse of compressed air through a blow pipe down into a nozzle mounted directly above each individual filter bag. This burst of compressed air is blown downwards into each bag. Each row of bags receives a short pulse of air for approximately 100 ~ 450m seconds duration. The pressurized air generates a compression wave down each bag, causing it to shake off the collected dust on the bag filter into the hopper below. Only a portion of the filter bags are cleaned at a time to limit or prevent down time.

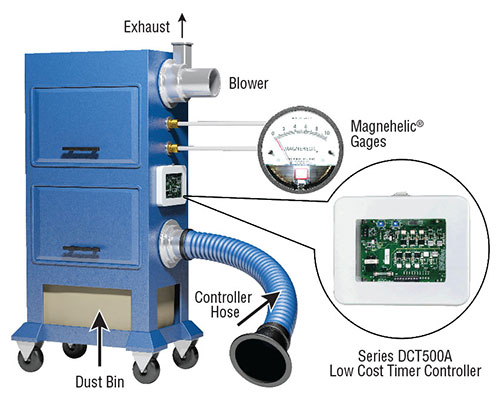

To monitor the pressure drop across the filters, the manufacturer supplies a Magnehelic® Differential Pressure Gage, Series 2000. When the pressure drop (due to dust build up on the filter) indicates that cleaning is necessary, the Dust Collector Timer Controller, Series DCT500ADC, is manually activated to initiate a cleaning cycle which involves solenoid valves releasing pulses of air. This process removes the dust from the filters where it drops into a storage bin. A Minihelic® Differential Pressure Gage, Series 2-5000, can be used instead of the Magnehelic® gage, and, if automatic cleaning is required, a Photohelic® Differential Pressure Switch/Gage, Series A3000, can provide the electrical contact to actuate the cleaning cycle when the pressure drop reaches the preset limit.

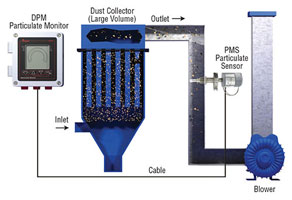

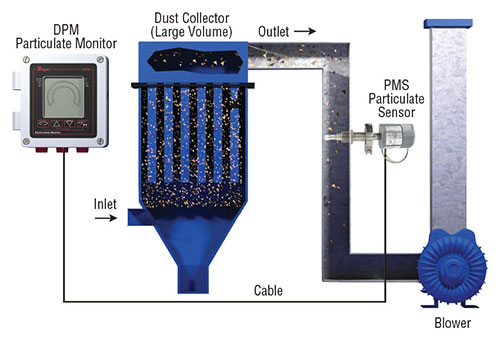

In the event that a filter bag is torn, dust particulates will slip through and exit the clear plenum. Depending on the industry, this may lead to an EPA Violation. The Particulate Monitor, Series DPM, and Particulate Sensor, Series PMS, combine to make a particulate monitoring system for the exhaust stream of dust collectors. The amount of particulate leaking out of the dust collector is measured using low maintenance induction technology and shown on a display for easy viewing. The DPM has programmable thresholds of leakage for switch output indication of dust collector problems such as broken or leaking filters. Proper use of the system will allow the user to catch breaking filters early. Advantages of this system include maintaining regulatory compliance, maximizing product recovery, optimizing filtration efficiency, preventing fines and plant shutdowns, and reducing the amount of pollutants released.

To learn more or order any Dwyer product, please visit our website.