Dwyer Instruments, Inc. manufactures and offers many temperature measuring products that use a thermistor as the sensing element.

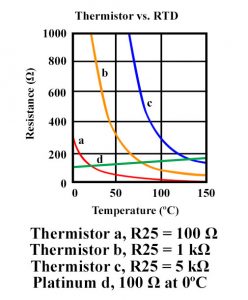

Thermistors are based on the principal that the electrical resistance of semiconductor materials is a function of the temperature. Thermistors work well over smaller temperature ranges with better accuracy than (RTD) but are very non-linear. They also generally offer better response times. Thermistors have much higher resistance values than RTDs, with ranges typically ranging from 100 ohms to 100 megaohms.

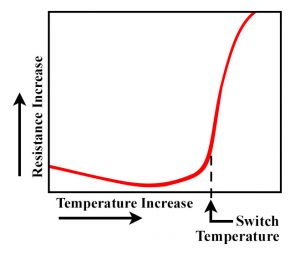

There two main types of thermistors based on temperature response: Positive Temperature Coefficient (PTC) and Negative Temperature Coefficient (NTC). With PTC, the resistance increases with increasing temperature. PTC thermistors are formed by using semiconductor materials along with polycrystalline ceramic. A PTC thermistor has an extremely large resistance change for small temperature changes and has a critical switch temperature where the resistance begins to change quickly (as shown in the graph below). This behavior makes them well suited for on-off use as a switch.

With NTC, the resistance decreases with increasing temperature. NTC thermistors are formed with sintered metal oxides made of transition metals such as nickel, manganese, copper, iron, and cobalt. They can also be constructed of semiconductor materials of silicon or germanium. NTC thermistors are commonly used to measure temperature over a specific range. NTC’s are designated by their resistance value and temperature curve such as a 10K Type 3.

Thermistors come in several styles of construction depending on the application need.

These include rods, beads, discs, washers, and flakes.

Since thermistors have such high resistance ranges, they are two wire devices. Lead wire resistance has little to no effect. Thermistors are wired directly to the measuring instrument or they can be extended with insulated electrical copper wire. Sensor wires should never be run in conduit with power sources, as this can create noise problems.