Hot-wire anemometers are often used in a hospital environment to measure and maintain room pressurization/de-pressurization. These applications require a positive pressure in operating rooms where bacteria cannot be allowed to enter, or a negative pressure in a quarantine environment to ensure that all bacteria will stay within the room.

Hot-wire anemometers are often used in a hospital environment to measure and maintain room pressurization/de-pressurization. These applications require a positive pressure in operating rooms where bacteria cannot be allowed to enter, or a negative pressure in a quarantine environment to ensure that all bacteria will stay within the room.

Hot-wire anemometers utilize a small open tipped probe with a thin wire going across the opening. This wire picks up readings by sending a small signal through itself to measure the dissipation of that signal. It is important to use these products only in proper environments. If a particulate was to hit this wire at a high velocity, the device could take damage and no longer read properly, causing instability within the clean rooms being monitored. This may put patients at risk, and cost your company in energy consumption.

Hot-wire anemometers utilize a small open tipped probe with a thin wire going across the opening. This wire picks up readings by sending a small signal through itself to measure the dissipation of that signal. It is important to use these products only in proper environments. If a particulate was to hit this wire at a high velocity, the device could take damage and no longer read properly, causing instability within the clean rooms being monitored. This may put patients at risk, and cost your company in energy consumption.

Additionally, while hot-wire anemometers have a high initial accuracy, this accuracy is not very stable over time. These devices must be cleaned on a regular schedule to retain the inherent accuracies stated on the specifications data sheet. If this schedule is disregarded, the device will be in need of repair and calibration.

If the device you are using is suffering from poor upkeep or has been damaged by being implemented into improper environments, then there is no way to ensure that these rooms are being kept in the proper state. This can lead to forcing fans to work overtime, wasting energy, or leaving fans off when they need to running.

If the device you are using is suffering from poor upkeep or has been damaged by being implemented into improper environments, then there is no way to ensure that these rooms are being kept in the proper state. This can lead to forcing fans to work overtime, wasting energy, or leaving fans off when they need to running.

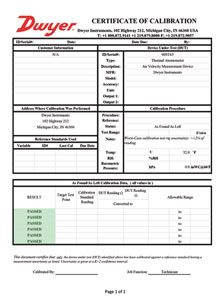

The best way to avoid these issues would be to follow the upkeep mentioned above. You may also wish to send these units back for a NIST traceable calibration annually. This test will give you six points of test data across the product’s range to ensure that the unit is still operating at its original accuracy.

The best way to avoid these issues would be to follow the upkeep mentioned above. You may also wish to send these units back for a NIST traceable calibration annually. This test will give you six points of test data across the product’s range to ensure that the unit is still operating at its original accuracy.

Dwyer offers several hot-wire anemometers, including the Thermo-Anemometer Probe, Series AP2, and the Thermo-Anemometer Test Instrument, Model 471B.

The Series AP2 wirelessly measures air velocity, air flow, and temperature when combined with the Universal Handheld, Model UHH2, or a mobile device using the Mobile Meter® Software Test Instrument App. In order to prevent damage to the sensing element, the AP2 probe has a protective sleeve that slides over the sensor when it is not in use. Markings on the probe allow users to know the insertion depth to obtain better accuracy when traversing a duct. This probe features a stable 50 ft (15 m) wireless range and allows for one-handed operation for ladder use safety.

The Thermo-Anemometer Test Instrument, Model 471B, is a versatile dual-function unit that quickly and easily measures air velocity or volumetric flow as well as air temperature in imperial or metric units. The instrument includes a stainless steel probe with a comfortable hand grip and etched insertion depth marks. The extruded aluminum housing fully protects electronics, yet is lightweight and comfortable to hold, while the integral sliding cover protects the probe sensors when not in use. The 471B is able to store up to 99 readings and features a high-contrast backlit LCD for visibility in any condition.