Lift stations are used to transmit wastewater to a treatment facility. In residential areas, lift stations may be located in a central point to a subdivision or community. Lift stations are pits located at points in the wastewater system to collect the wastewater and usually have two submersible pumps. In order to use gravity to move the wastewater along, it must be continually elevated to provide height to generate the flow. Wastewater in the lift station is pumped out to a higher level, from where it can flow on to the next lift station or to the treatment facility. As excavation and trenching for sewer pipes can be costly, using lift stations (and gravity) saves a substantial amount of money.

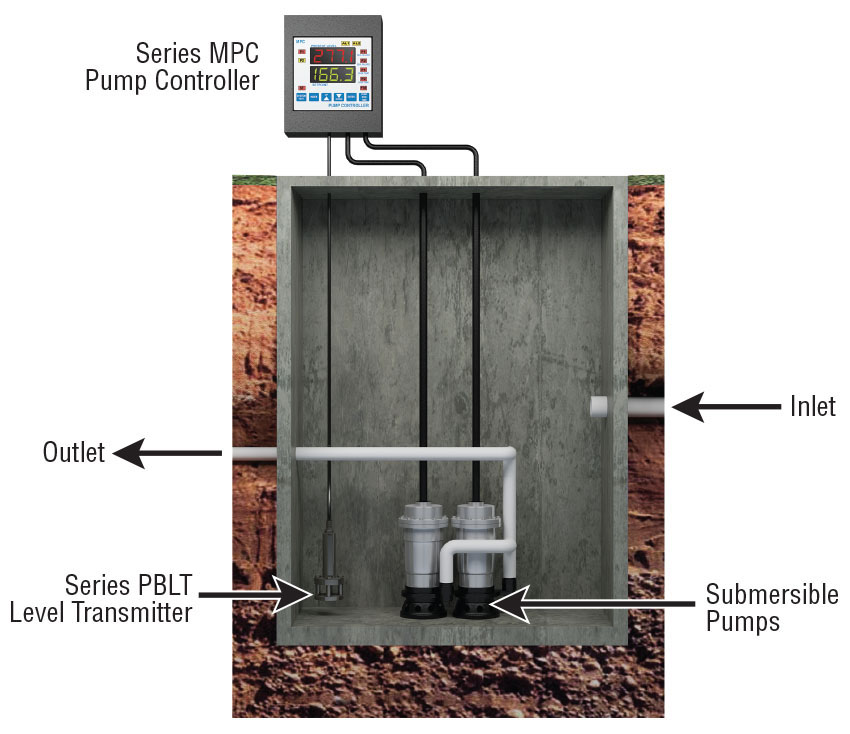

The Series MPC pump controller is used with the Series PBLT2/PBLTX level transmitter to control the level in a lift station. The PBLT2/PBLTX is a level transmitter that is submersed in the tank and sends a linear output of the height of wastewater above it. The MPC takes the height input and controls the pumps according to how it has been programmed. For a lift station, the primary pump comes on when the tank hits a high level and turns off when the level decreases to the set low level. The second pump is used if the first pump cannot drain the station and comes on at a set higher level above the pump. High and low level alarms, submersible pump seal failure indication, pump over temperature protection, and pump alteration all are built into the MPC.

If you have any questions, the Dwyer Applications Engineers are available to assist by phone at (219) 879-8000 x6402, or by email at tech@dwyermail.com.

To learn more about Dwyer’s lift station application solutions, please read our article here: https://blog.dwyer-inst.com/2021/01/06/lift-station-level-sensing/