Several applications require manual reset switches, which are switches that need to be physically reset by an individual for a process to continue or restart. A manual reset is often needed when an area has to be inspected prior to equipment restart. This can help to ensure the safety/inspection of both equipment and other individuals in the area.

Some switches have a mechanical manual reset (such as the Dwyer Series 1900, 1831, and 1800). However, there may be a need to have a manual reset for applications beyond what these switches are designed for. If a pump is allowed to run with a clogged filter, for example, this may severely damage the pump. Continue reading “How to Program a Switch for Manual Reset”

Differential pressure measurement can be beneficial in a wide variety of building automation system (BAS) applications.

Differential pressure measurement can be beneficial in a wide variety of building automation system (BAS) applications.

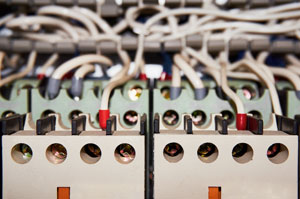

Intermediate relays are crucial in the proper function and operation of several varieties of power equipment, be it in mobile refrigeration or a simple pump application. But what are intermediate relays, and how are they implemented?

Intermediate relays are crucial in the proper function and operation of several varieties of power equipment, be it in mobile refrigeration or a simple pump application. But what are intermediate relays, and how are they implemented?

Motors are used for numerous industrial processes, be it moving air with a fan, pumping water with a pump, or driving a mechanical process. It is important to know when motors are not operating properly or require maintenance.

Motors are used for numerous industrial processes, be it moving air with a fan, pumping water with a pump, or driving a mechanical process. It is important to know when motors are not operating properly or require maintenance.