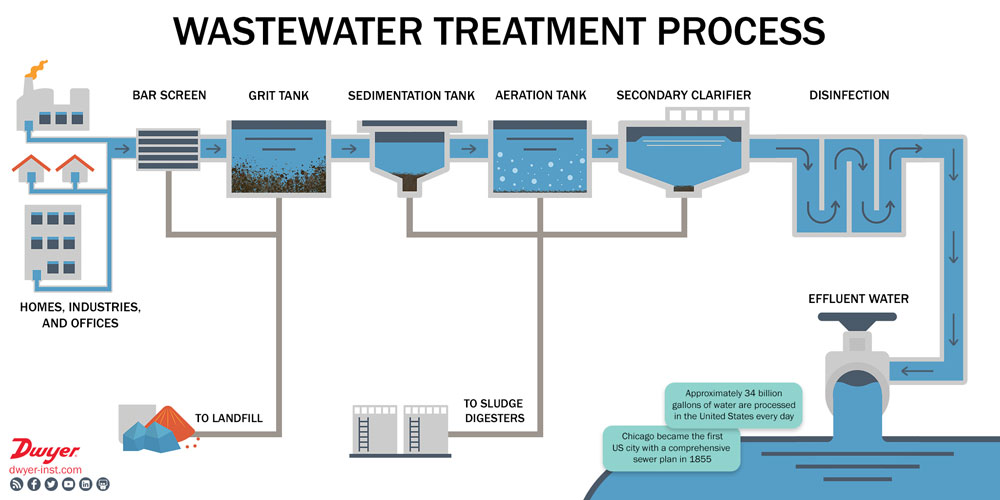

Every day, billions of gallons of wastewater are collected from our homes, businesses, and industries. Wastewater is exactly what it sounds like: water that has already been used and disposed of via a tub, toilet, sink, or storm drains. Because it is full of contaminants that make the water no longer suitable for use, it is collected in the sewer system and delivered to plants for treatment to make the water safe to be returned to the environment. Continue reading “What is Wastewater, and How is it Treated?”