Dwyer’s Account Executive for our test equipment portfolio, Jaden Lane, recently interviewed Erik from Technical Balance to learn more about his job, company, and relationship with Dwyer. Continue reading “An Interview with Technical Balance”

Dwyer’s Account Executive for our test equipment portfolio, Jaden Lane, recently interviewed Erik from Technical Balance to learn more about his job, company, and relationship with Dwyer. Continue reading “An Interview with Technical Balance”

Measuring Flow with Piston Displacement Meters

If you’re looking to purchase a new water meter, it can be hard to discern what type of meter you should pick. There are many things to consider, from the body material to the outputs to whether any approvals are required. One of the most important considerations for selecting a meter for your application is how the meter will be installed, as certain technologies can limit the meter’s installation orientation. For example, multi-jet meters measure flow by generating multiple jets of water against an impeller in an internal chamber. As the impeller rotates, the flow is totalized on the meter face. In order to meet the stated accuracy, multi-jet meters must be installed horizontally. If a multi-jet meter is installed vertically, the impeller will not rotate correctly and the readings will not meet the stated accuracy specification. Continue reading “Measuring Flow with Piston Displacement Meters”

If you’re looking to purchase a new water meter, it can be hard to discern what type of meter you should pick. There are many things to consider, from the body material to the outputs to whether any approvals are required. One of the most important considerations for selecting a meter for your application is how the meter will be installed, as certain technologies can limit the meter’s installation orientation. For example, multi-jet meters measure flow by generating multiple jets of water against an impeller in an internal chamber. As the impeller rotates, the flow is totalized on the meter face. In order to meet the stated accuracy, multi-jet meters must be installed horizontally. If a multi-jet meter is installed vertically, the impeller will not rotate correctly and the readings will not meet the stated accuracy specification. Continue reading “Measuring Flow with Piston Displacement Meters”

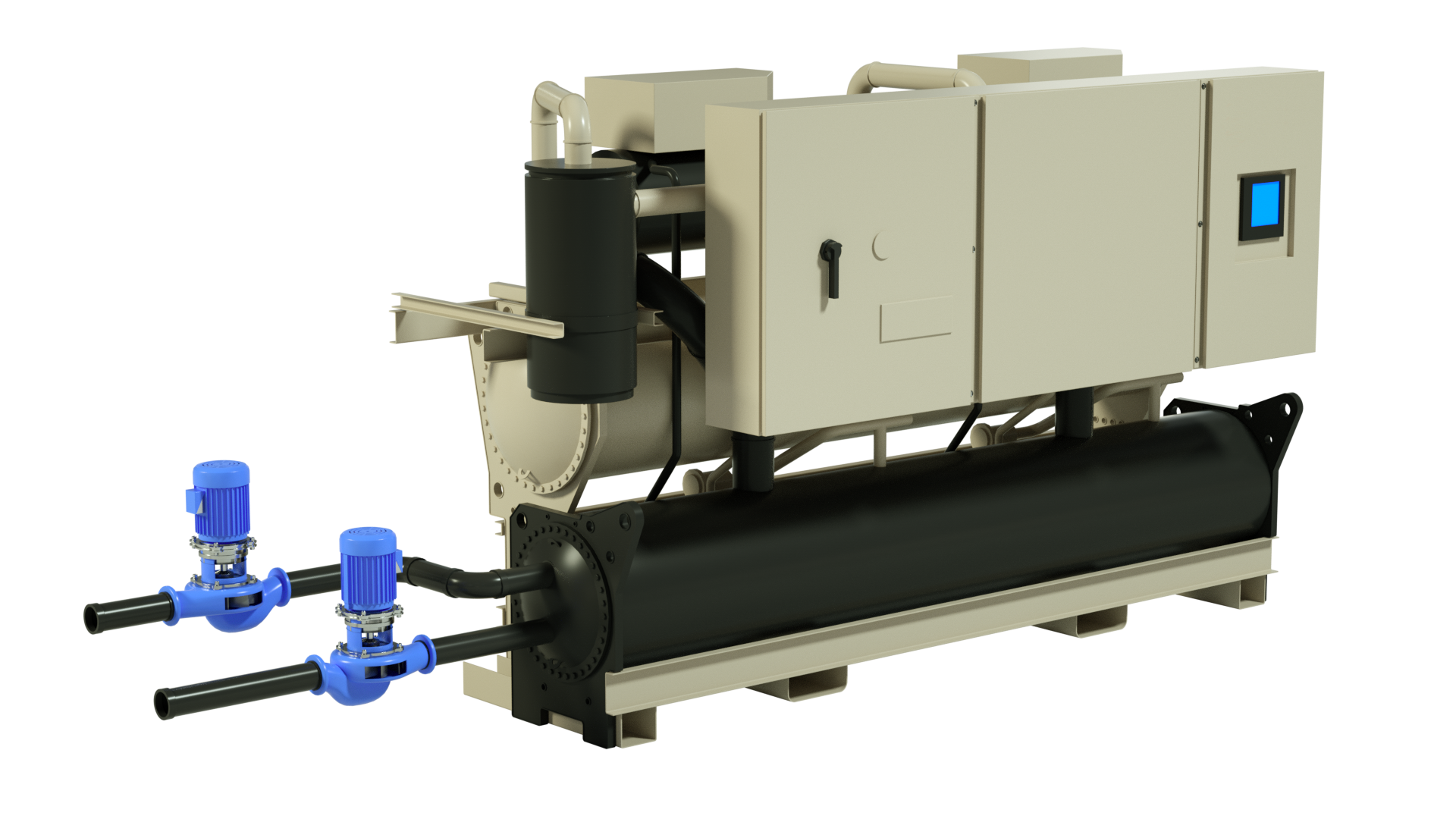

Proving Flow Through Chillers

Water chillers are nothing new, with nearly an estimated 100,000 units operating in North America alone. Chillers are the cooling machines of choice to condition industrial, commercial, and institutional facilities. They are used to lower the temperatures of all kinds of equipment and processes such as: robotic machinery; semiconductors; injection and blow molding machines; welding equipment; die-casting and machine tooling; paper and cement processing; power supplies; power generation stations; compressed air and gas cooling systems; medical imaging machines; chemical, drug, food and beverage production; even simply to cool potable water to desirable levels. Whether for office comfort, keeping data server centers from overheating, or specialized industrial processes, water temperature control plays a vital role in many of the behind-the-scenes activities that affect our everyday lives. Continue reading “Proving Flow Through Chillers”

Water chillers are nothing new, with nearly an estimated 100,000 units operating in North America alone. Chillers are the cooling machines of choice to condition industrial, commercial, and institutional facilities. They are used to lower the temperatures of all kinds of equipment and processes such as: robotic machinery; semiconductors; injection and blow molding machines; welding equipment; die-casting and machine tooling; paper and cement processing; power supplies; power generation stations; compressed air and gas cooling systems; medical imaging machines; chemical, drug, food and beverage production; even simply to cool potable water to desirable levels. Whether for office comfort, keeping data server centers from overheating, or specialized industrial processes, water temperature control plays a vital role in many of the behind-the-scenes activities that affect our everyday lives. Continue reading “Proving Flow Through Chillers”

[New Product Highlight] StabiliSENSE™ Critical Room Pressure Monitor | Series RPMC

The Dwyer team recently released the StabiliSENSE™ critical room pressure monitor, Series RPMC. This series is ideal for critical low differential room pressure applications, such as: clean manufacturing areas, semiconductor manufacturing, pharmaceutical, clean rooms, research labs, and vivariums. Continue reading “[New Product Highlight] StabiliSENSE™ Critical Room Pressure Monitor | Series RPMC”

The Dwyer team recently released the StabiliSENSE™ critical room pressure monitor, Series RPMC. This series is ideal for critical low differential room pressure applications, such as: clean manufacturing areas, semiconductor manufacturing, pharmaceutical, clean rooms, research labs, and vivariums. Continue reading “[New Product Highlight] StabiliSENSE™ Critical Room Pressure Monitor | Series RPMC”

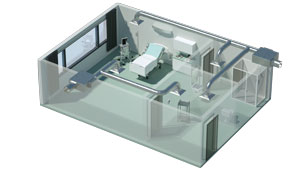

What Are Room Pressure Monitors and Where Are They Used?

Room pressure monitors are devices that monitor differential pressure between two rooms or areas. Differential pressure is the difference of two pressures being sensed.

There are several applications where it is important to maintain a pressure difference between two rooms. This helps to ensure that there are no contaminants entering or exiting a protected area. In a medical setting, an isolation room requires a pressure differential to make sure that no bacteria, pathogens, or viruses enter (or leave) the isolation room. This protects healthcare professionals, patients, and other guests, and minimizes the spread of germs. Room pressure monitors would also be used in areas such as: pharmaceutical manufacturing, semiconductor manufacturing, clean rooms, research labs, vivariums, and clean manufacturing areas. Continue reading “What Are Room Pressure Monitors and Where Are They Used?”