Electromagnetic flowmeters, also known as magnetic flowmeters or magmeters, use Faraday’s Law of Electromagnetic Induction to determine the flow of liquid in a pipe. In an electromagnetic flowmeter, a magnetic field is generated and channeled into the liquid flowing through the pipe. Following Faraday’s Law, flow of a conductive liquid through the magnetic field will cause a voltage signal to be sensed by electrodes located on the flow tube walls. When the fluid moves faster, more voltage is generated. Faraday’s Law states that the voltage generated is proportional to the movement of the flowing liquid. The electronic transmitter processes the voltage signal to determine liquid flow.

Electromagnetic flowmeters, also known as magnetic flowmeters or magmeters, use Faraday’s Law of Electromagnetic Induction to determine the flow of liquid in a pipe. In an electromagnetic flowmeter, a magnetic field is generated and channeled into the liquid flowing through the pipe. Following Faraday’s Law, flow of a conductive liquid through the magnetic field will cause a voltage signal to be sensed by electrodes located on the flow tube walls. When the fluid moves faster, more voltage is generated. Faraday’s Law states that the voltage generated is proportional to the movement of the flowing liquid. The electronic transmitter processes the voltage signal to determine liquid flow.

In contrast with many other flowmeter technologies, electromagnetic flowmeter technology produces signals that are linear with flow. As such, the turndown associated with magnetic flowmeters can approach 20:1 or better without sacrificing accuracy. Continue reading “How Electromagnetic Flowmeters Work”

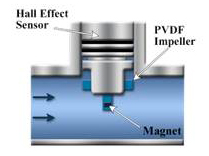

Paddle movement is often detected magnetically, with each paddle or embedded piece of metal generating a pulse. When the fluid moves faster, more pulses are generated. The transmitter processes the pulse signal to determine the flow of the fluid.

Paddle movement is often detected magnetically, with each paddle or embedded piece of metal generating a pulse. When the fluid moves faster, more pulses are generated. The transmitter processes the pulse signal to determine the flow of the fluid.

Valves are used to handle a wide variety of functions in controlling the flow of liquids and gases. With so many options available, it’s important to look at all of the factors to ensure you are selecting the correct valve for your application.

Valves are used to handle a wide variety of functions in controlling the flow of liquids and gases. With so many options available, it’s important to look at all of the factors to ensure you are selecting the correct valve for your application.