Dwyer Instruments offers a multitude of sensors for monitoring air velocity in HVAC systems. Some of this instrumentation has a simple construction (Pitot tubes, for example) while others are more complex, such as hot-wire anemometers.

Dwyer Instruments offers a multitude of sensors for monitoring air velocity in HVAC systems. Some of this instrumentation has a simple construction (Pitot tubes, for example) while others are more complex, such as hot-wire anemometers.

The initial term and first “hot-wire anemometer” was developed back in 1914 by Louie Vesso King. He is also accredited for King’s Law, which mathematically describes heat transfer in air flows using a heated wire. As the air moves over the wire, it causes a loss of temperature in the wire and removes some of the wire’s heat energy. Continue reading “Understanding Air Velocity Sensors”

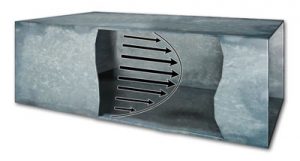

The velocity of an air stream in a duct is not uniform over the cross section of the duct. This is because friction against duct walls causes the air velocity to be lower near the sides than the velocity in the center, creating a parabolic velocity profile.

The velocity of an air stream in a duct is not uniform over the cross section of the duct. This is because friction against duct walls causes the air velocity to be lower near the sides than the velocity in the center, creating a parabolic velocity profile.

Differential pressure measurement can be beneficial in a wide variety of building automation system (BAS) applications.

Differential pressure measurement can be beneficial in a wide variety of building automation system (BAS) applications.