Partially or completely closed school facilities have been the reality of many school corporations and families across the country since we were struck by the COVID-19 pandemic. It has effectively targeted our preparedness; changing how we view building’s HVAC systems, indoor air quality (IAQ), and even how parents and teachers view which schools are the safest, best institutions for themselves and their families. Continue reading “During the Pandemic: A Study of School Air Management”

Partially or completely closed school facilities have been the reality of many school corporations and families across the country since we were struck by the COVID-19 pandemic. It has effectively targeted our preparedness; changing how we view building’s HVAC systems, indoor air quality (IAQ), and even how parents and teachers view which schools are the safest, best institutions for themselves and their families. Continue reading “During the Pandemic: A Study of School Air Management”

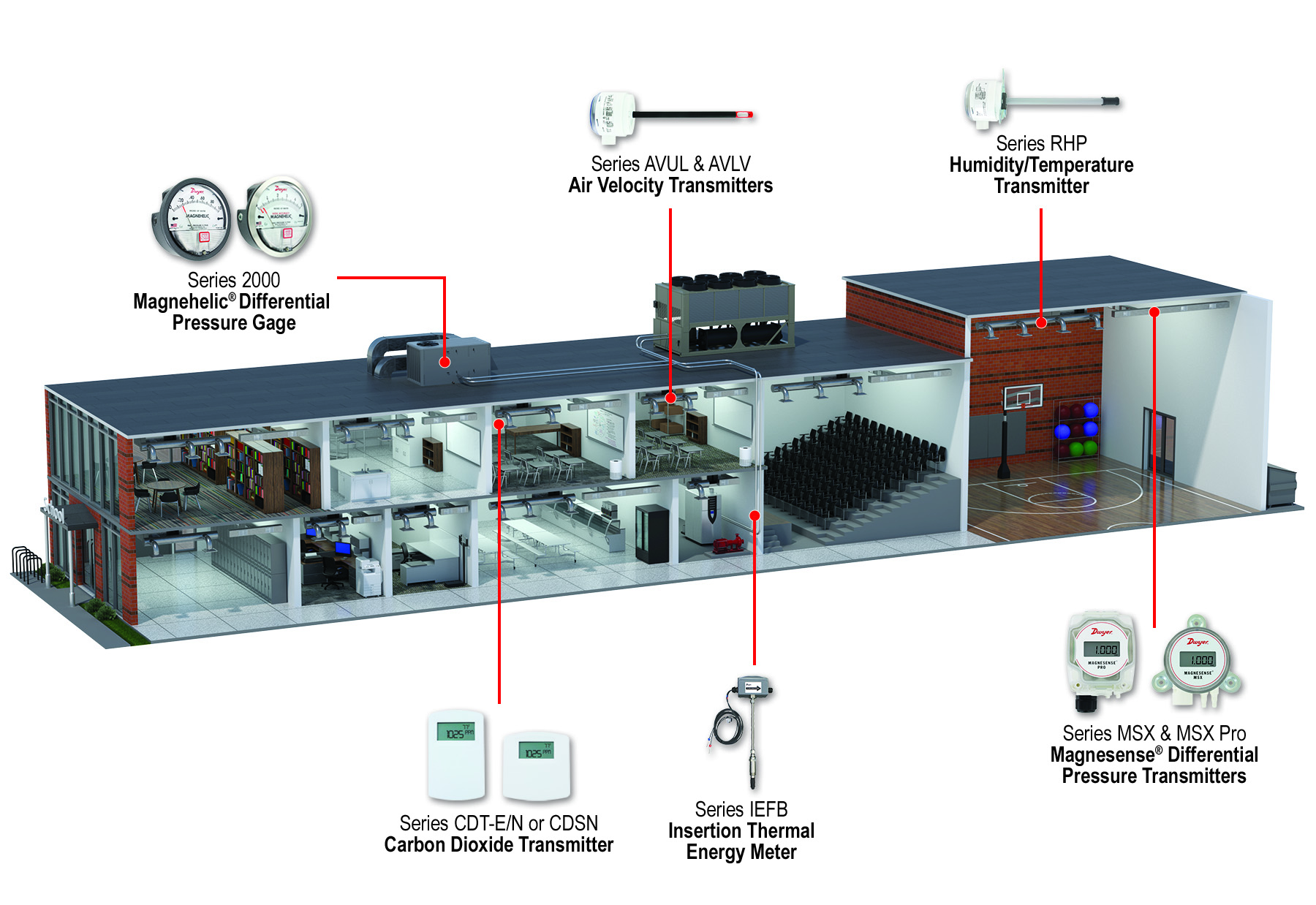

Ensuring Comfortable, Safe Environments in Schools

Dwyer® products are used to monitor and improve parameters that make up indoor air quality (IAQ) such as building pressure, temperature, humidity, carbon dioxide (CO2), and volatile organic compounds. This is particularly important for areas like schools, where students and teaching staff will be present for long periods of time. Our products are used in all areas of the building, including classrooms, gymnasiums, auditoriums, and nurse offices. Continue reading “Ensuring Comfortable, Safe Environments in Schools”

[New Product Highlight] StabiliSENSE™ Critical Room Pressure Monitor | Series RPMC

The Dwyer team recently released the StabiliSENSE™ critical room pressure monitor, Series RPMC. This series is ideal for critical low differential room pressure applications, such as: clean manufacturing areas, semiconductor manufacturing, pharmaceutical, clean rooms, research labs, and vivariums. Continue reading “[New Product Highlight] StabiliSENSE™ Critical Room Pressure Monitor | Series RPMC”

The Dwyer team recently released the StabiliSENSE™ critical room pressure monitor, Series RPMC. This series is ideal for critical low differential room pressure applications, such as: clean manufacturing areas, semiconductor manufacturing, pharmaceutical, clean rooms, research labs, and vivariums. Continue reading “[New Product Highlight] StabiliSENSE™ Critical Room Pressure Monitor | Series RPMC”

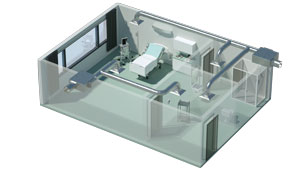

What Are Room Pressure Monitors and Where Are They Used?

Room pressure monitors are devices that monitor differential pressure between two rooms or areas. Differential pressure is the difference of two pressures being sensed.

There are several applications where it is important to maintain a pressure difference between two rooms. This helps to ensure that there are no contaminants entering or exiting a protected area. In a medical setting, an isolation room requires a pressure differential to make sure that no bacteria, pathogens, or viruses enter (or leave) the isolation room. This protects healthcare professionals, patients, and other guests, and minimizes the spread of germs. Room pressure monitors would also be used in areas such as: pharmaceutical manufacturing, semiconductor manufacturing, clean rooms, research labs, vivariums, and clean manufacturing areas. Continue reading “What Are Room Pressure Monitors and Where Are They Used?”

How to Program a Switch for Manual Reset

Several applications require manual reset switches, which are switches that need to be physically reset by an individual for a process to continue or restart. A manual reset is often needed when an area has to be inspected prior to equipment restart. This can help to ensure the safety/inspection of both equipment and other individuals in the area.

Some switches have a mechanical manual reset (such as the Dwyer Series 1900, 1831, and 1800). However, there may be a need to have a manual reset for applications beyond what these switches are designed for. If a pump is allowed to run with a clogged filter, for example, this may severely damage the pump. Continue reading “How to Program a Switch for Manual Reset”