There are several different component parts that go into a dust collector for monitoring and control purposes. In this article, we are going to focus on timer boards. We will be comparing and contrasting a few of our timer boards, as well as discussing how we could help you to better protect your equipment in the most cost-effective manner. Continue reading “Dust Collector Timer Controllers”

There are several different component parts that go into a dust collector for monitoring and control purposes. In this article, we are going to focus on timer boards. We will be comparing and contrasting a few of our timer boards, as well as discussing how we could help you to better protect your equipment in the most cost-effective manner. Continue reading “Dust Collector Timer Controllers”

Manufacturing an Economic Dust Filtration System

Many customers have come to the Dwyer team asking: “What can Dwyer do to help with lean manufacturing?” In this article, we will discuss the Dwyer® Series SVT solenoid valve and timer enclosure and its cost savings advantages in a dust filtration system.

The Series SVT combines two integral components in a dust filtration system into one package: solenoid valves and a timer controller. In a dust filtration system, solenoid valves are used to send air through a pulse valve, such as our Series RDCS. Pulse valves release a quick spurt of air into a dirty dust cartridge filter, which, in turn, releases the dust from the filter. The timer portion of the dust filtration system is the brains of the operation controlling when the solenoids fire, the amount of time the solenoids are open, and when the next solenoid in the sequence fires. Continue reading “Manufacturing an Economic Dust Filtration System”

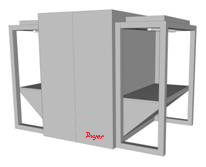

Downdraft Table Applications

There are many manufacturing processes that require human operators to perform tasks, which can create hazardous levels of particulate, fumes, gases, vapors, and mists. A few of these processes include: welding, sanding, grinding, brazing, laser cutting, tempering, and quenching. The Occupational Safety and Health Administration (OSHA) has regulatory requirements to reduce worker’s exposure to these hazards, which can cause respiratory and other health issues. Downdraft tables are workstations designed to better protect the operators who perform these tasks, in a bench top setting, by removing the hazardous material that laden the air from the worker’s breathing zone. Continue reading “Downdraft Table Applications”

Dust Collector Timer Controllers

There are several different component parts that go into a dust collector for monitoring and control purposes. In this article, we are going to focus on timer boards. We will be comparing and contrasting a few of our timer boards, as well as discussing how we could help you to better protect your equipment in the most cost-effective manner. Continue reading “Dust Collector Timer Controllers”

There are several different component parts that go into a dust collector for monitoring and control purposes. In this article, we are going to focus on timer boards. We will be comparing and contrasting a few of our timer boards, as well as discussing how we could help you to better protect your equipment in the most cost-effective manner. Continue reading “Dust Collector Timer Controllers”

Maintain Continuous Operation from Leaking Pulse-Jet Bag Filters

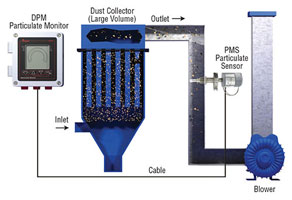

Dust Collector

Dust Collector

A dust collector is a system used to improve the quality of air within an industrial and commercial environment by collecting dust and other impurities from the air. Continue reading “Maintain Continuous Operation from Leaking Pulse-Jet Bag Filters”