Maintaining efficiency in wet chemical scrubbers has become one of the most important missions of current APC facilities due to urban growth and plant expansion/modernization projects as good stewards of the community. Systems often run above the 90% efficiency mark with the help of accurate make-up water control instruments.

One of the most important components that control the make-up water and sump level are variable area flowmeters.

Dwyer has dialed in the control with the Series RM Rate-Master® variable area polycarbonate flowmeters (often called a rotameter) that offer an excellent option to maintain specific flow rates.

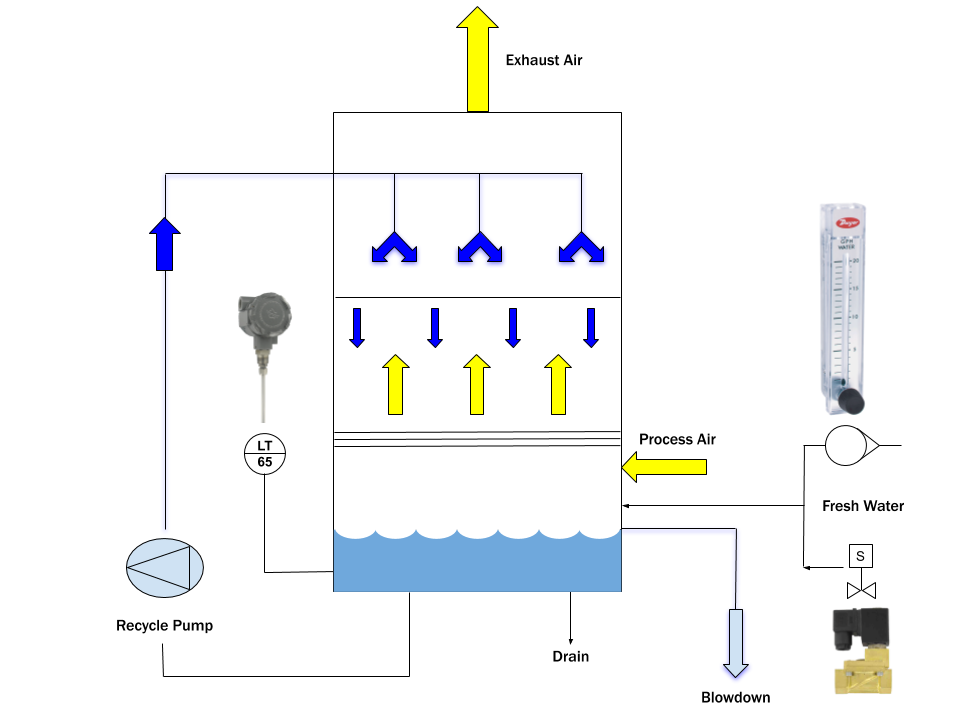

Most wet scrubbers systems recirculate the scrubbing liquid. In order to decrease the overloading of pollutant content of the scrubbing liquid (solvent), part of the liquid is batch or continuously bled from the system and fresh water is added. A proper equilibrium can be maintained in conjunction with level instrumentation, emergency make-up solenoids, and analytical chemical feed control instrumentation.

Sump over-saturation due to poor make-up water control is one area that can be fixed with high quality and accurate designs, making for years of trouble-free operational costs.

The Dwyer family of flowmeters offer industry-best direct read scales for easy operator use, adjustment valve, shatterproof face, and precision injection molding with integral flow channels for accurate and repeatable control.

Flowmeters are just one part of the sump level control systems that also utilize continuous level monitoring instrumentation.

Capacitive level transmitters like the Dwyer Series CLS2 provide accurate continuous sump level monitoring (4-20 mA output) that will ensure that sump levels are fast and accurately monitored. In the event of an emergency loss of water, they can transmit data to the SCADA to alarm the recycle pump protection systems, as well as energize make-up water solenoid actuation.

Emergency make-up water control can be accomplished with solutions like the Dwyer Series SBSV and SSV 2-way guided coil-type solenoid valves. Simple and reliable on/off designs take the guesswork out of modulating control valves and can provide instant on/off demand water addition.

Every day more and more resources are devoted to combating odor control by installing and upgrading current facilities. Proper and accurate make-up water control can make your wet chemical scrubbers work more efficiently. It can also help reduce waste water and that would require additional treatment before discharge back to natural water resources.

Every component in sump level controls starts with water level management. Reach out today for a Dwyer solution to suit your application’s needs.