The curtain has fallen on two fantastic tradeshows, AHR Expo and World of Concrete, and we’re still buzzing with excitement! We want to extend a heartfelt thank you to all the amazing customers, partners, and teammates who made these events unforgettable. Continue reading “Reflections: AHR Expo, World of Concrete, and What’s Next!”

Upcoming Tradeshows: Innovation at AHR Expo and World of Concrete

As the new year unfolds, Dwyer Instruments is gearing up to showcase its innovative solutions at two prominent tradeshows in January: AHR Expo and World of Concrete. These events provide a unique platform for professionals and enthusiasts to explore Dwyer’s latest offerings and engage in discussions about industry advancements.

Continue reading “Upcoming Tradeshows: Innovation at AHR Expo and World of Concrete”

Precision on Demand: Dwyer’s Online Product Configurator and Fast Track Program

In the dynamic landscape of industrial instrumentation, every application has its unique demands. We want to ensure that our products meet your application needs. To do that, Dwyer Instruments provides not only a user-friendly online product configurator, but also a Fast Track Program for a fully customized solution.

In the dynamic landscape of industrial instrumentation, every application has its unique demands. We want to ensure that our products meet your application needs. To do that, Dwyer Instruments provides not only a user-friendly online product configurator, but also a Fast Track Program for a fully customized solution.

Continue reading “Precision on Demand: Dwyer’s Online Product Configurator and Fast Track Program”

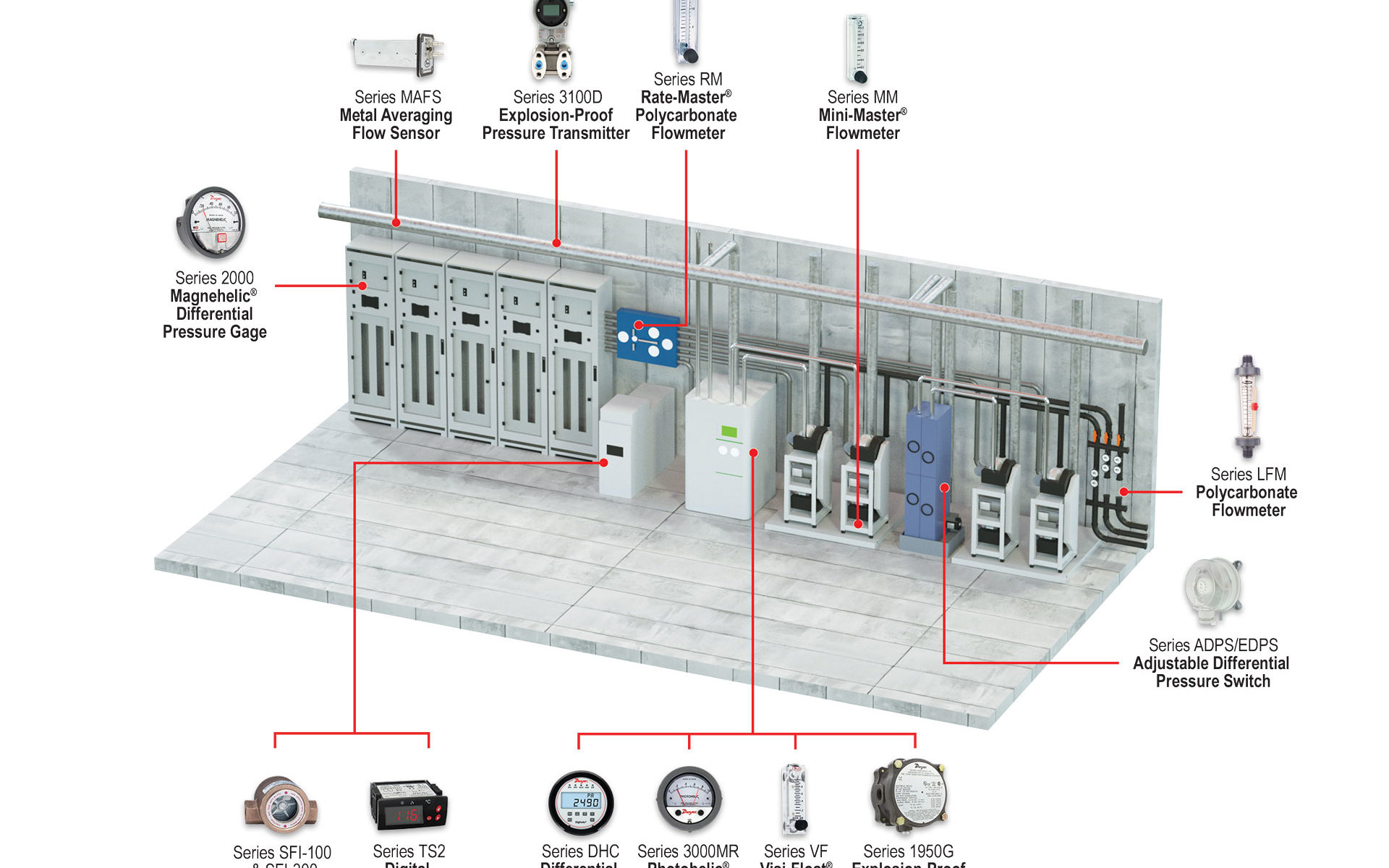

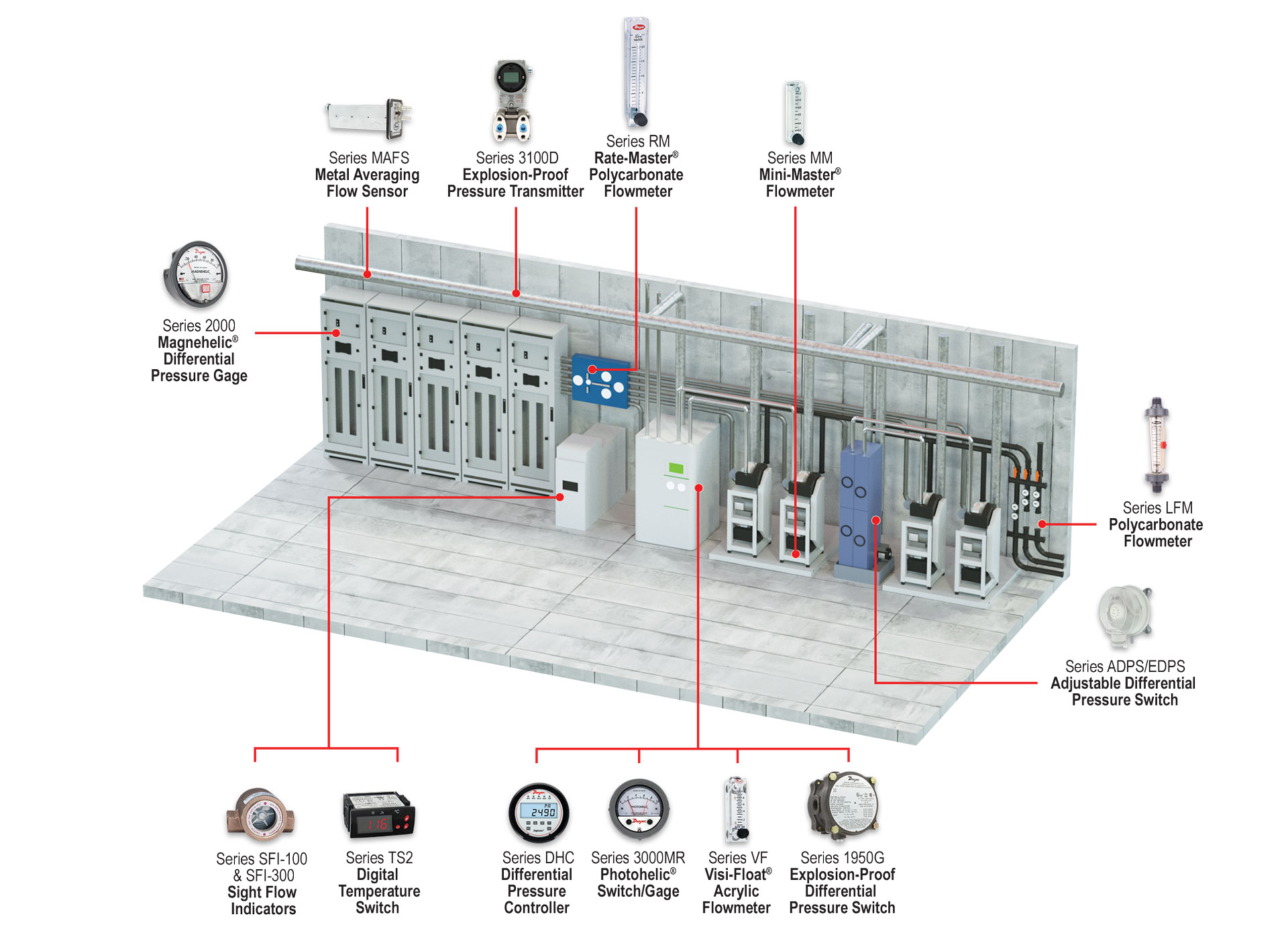

Monitoring Solutions for Semiconductor Subfabs

A semiconductor transistor is a part with specific electronic properties that allow it to serve as a component in microchips and modern electronics like phones, laptops, and more. As these components are small and require precise manufacturing methods, there are facilities dedicated to their manufacture.

These facilities consist of several levels including air handlers and scrubbers for exhaust, HEPA room, fab cleanroom, and subfab areas. The control of pressure, flow, and temperature within the facility is essential.

Semiconductor subfabs are located directly below the cleanroom. Here you will find an array of ancillary equipment, such as vacuum pumps, abatement systems, chillers, gas cabinets, and other equipment to keep process tools functioning efficiently. The equipment within the subfab is interconnected with the tools found within the fab cleanroom itself; these separate but connected areas work together to make sure the facility runs smoothly. Continue reading “Monitoring Solutions for Semiconductor Subfabs”

5 Factors to Consider When Choosing a Valve

Valves are used to handle a wide variety of functions in controlling the flow of liquids and gases. With so many options available, it’s important to look at all of the factors to ensure you are selecting the correct valve for your application.

Valves are used to handle a wide variety of functions in controlling the flow of liquids and gases. With so many options available, it’s important to look at all of the factors to ensure you are selecting the correct valve for your application.

Continue reading “5 Factors to Consider When Choosing a Valve”