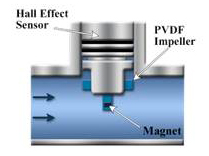

Paddlewheel flowmeters use the mechanical energy of the fluid to rotate a paddlewheel (just like a riverboat) in the flow stream. Paddles on the rotor are inserted into the flow to transform energy from the flow stream into rotational energy. The rotor shaft spins on bearings. When the fluid moves faster, the paddlewheel spins proportionally faster. Shaft rotation can be sensed mechanically or by detecting the movement of the paddles.

Paddle movement is often detected magnetically, with each paddle or embedded piece of metal generating a pulse. When the fluid moves faster, more pulses are generated. The transmitter processes the pulse signal to determine the flow of the fluid.

Paddle movement is often detected magnetically, with each paddle or embedded piece of metal generating a pulse. When the fluid moves faster, more pulses are generated. The transmitter processes the pulse signal to determine the flow of the fluid.

How to Use Paddlewheel Flowmeters

Paddlewheel flowmeters measure the velocity of liquids in pipes, such as chemicals, water, and liquids. High accuracy is attainable if carefully installed. These flowmeters are measuring flow at the edge of the flow profile and thus are affected by viscosity changes. The most common use is in a system where the fluid is like water and other variables such as pH/ORP, conductivity, pressure, temperature, and level are monitored. All sensors are inserted into the same pipe Ts and connect into one controller/transmitter. There are temperature and pressure limitations of this insertion system but it is very versatile. Applications for paddlewheel flowmeters are found in the water and chemical industries. Water applications include distribution systems. Miscellaneous applications are found in the food and beverage, and chemical industries.

Application Cautions for Paddlewheel Flowmeters

Paddlewheel flowmeters are less accurate at low flow rates due to rotor/bearing drag that slows the rotor. Make sure to operate these flowmeters above approximately 5 percent of maximum flow. Paddlewheel flowmeters should not be operated at high velocity because premature bearing wear and/or damage can occur. Be careful when measuring fluids that are non-lubricating because bearing wear can cause the flowmeter to become inaccurate and fail. In some applications, sensor replacement may need to be performed routinely and increase maintenance costs. Applications in dirty fluids are not recommended. Easy replacement with insertion magmeters is possible when high failure rates are unacceptable. In summary, paddlewheel flowmeters have moving parts that are subject to degradation with time and use.

Paddlewheel flowmeters are less accurate at low flow rates due to rotor/bearing drag that slows the rotor. Make sure to operate these flowmeters above approximately 5 percent of maximum flow. Paddlewheel flowmeters should not be operated at high velocity because premature bearing wear and/or damage can occur. Be careful when measuring fluids that are non-lubricating because bearing wear can cause the flowmeter to become inaccurate and fail. In some applications, sensor replacement may need to be performed routinely and increase maintenance costs. Applications in dirty fluids are not recommended. Easy replacement with insertion magmeters is possible when high failure rates are unacceptable. In summary, paddlewheel flowmeters have moving parts that are subject to degradation with time and use.

Abrupt transitions from gas flow to liquid flow should be avoided because they can mechanically stress the flowmeter, degrade accuracy, and/or damage the flowmeter. These conditions generally occur when filling the pipe and under slug flow conditions. Two-phase flow conditions can also cause flowmeters to measure inaccurately.

To learn about Dwyer’s paddlewheel flow transmitters, please visit: https://dwyer-inst.com/en/products/flow/flow-transmitters/paddlewheel-adjustable-insertion.html

—

Source: https://www.flowmeters.com/