The HVACR industry is evolving to create more energy efficient and sustainable ways to cool our homes and commercial buildings using eco-friendly refrigerants that are less damaging to the environment, but significantly more flammable than their predecessors. The UL standard 60335 aims to balance these greener refrigerants while still maintaining occupancy safety as it applies to “packaged air conditioners and heat pumps; partial units; liquid chillers and hydronic fan coil units; hot water heat pumps; dehumidifiers; supplemental heaters and equipment with flammable refrigerants1.”

The HVACR industry is evolving to create more energy efficient and sustainable ways to cool our homes and commercial buildings using eco-friendly refrigerants that are less damaging to the environment, but significantly more flammable than their predecessors. The UL standard 60335 aims to balance these greener refrigerants while still maintaining occupancy safety as it applies to “packaged air conditioners and heat pumps; partial units; liquid chillers and hydronic fan coil units; hot water heat pumps; dehumidifiers; supplemental heaters and equipment with flammable refrigerants1.”

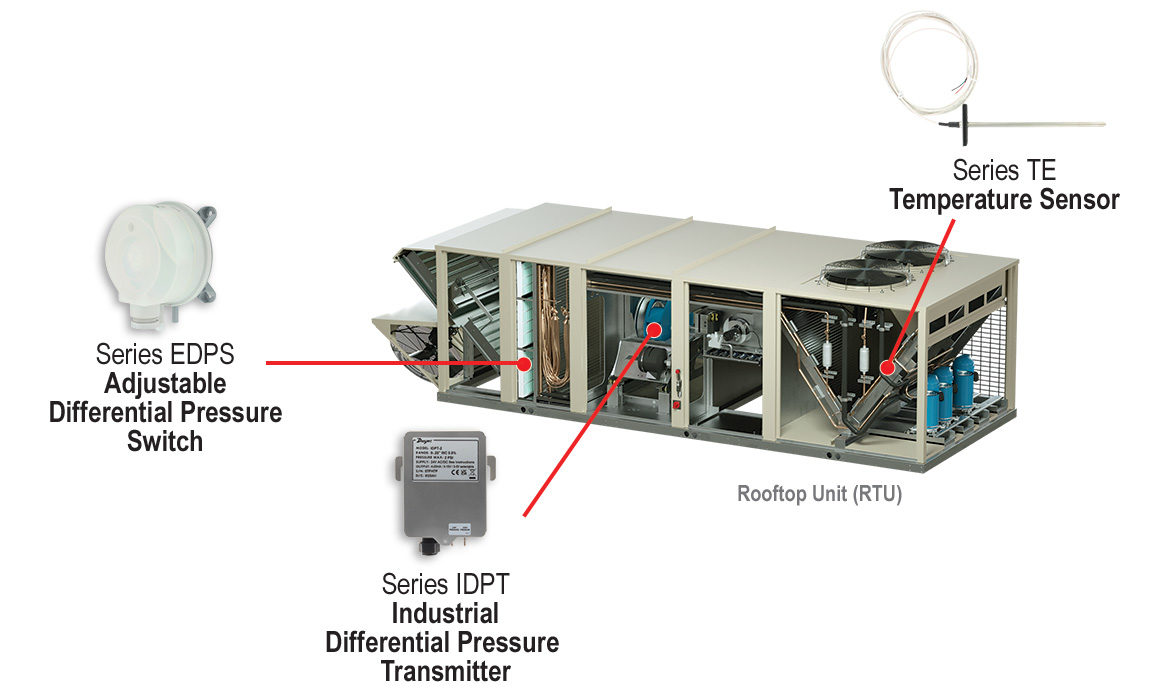

With this standard there are significant regulations put onto the plastics used in air handlers to meet certain burn and smoke criteria, as tested and approved by the UL Yellowcard. Some air handling equipment manufacturers are attempting to meet this specification for pressure transmitters and sensors by mounting pressure transmitters that are typically made of plastic in a metal enclosure or mounting them outside of the plenum spaces. Continue reading “Series IDPT: Built for Compliance”

There are several different component parts that go into a dust collector for monitoring and control purposes. In this article, we are going to focus on timer boards. We will be comparing and contrasting a few of our timer boards, as well as discussing how we could help you to better protect your equipment in the most cost-effective manner.

There are several different component parts that go into a dust collector for monitoring and control purposes. In this article, we are going to focus on timer boards. We will be comparing and contrasting a few of our timer boards, as well as discussing how we could help you to better protect your equipment in the most cost-effective manner.

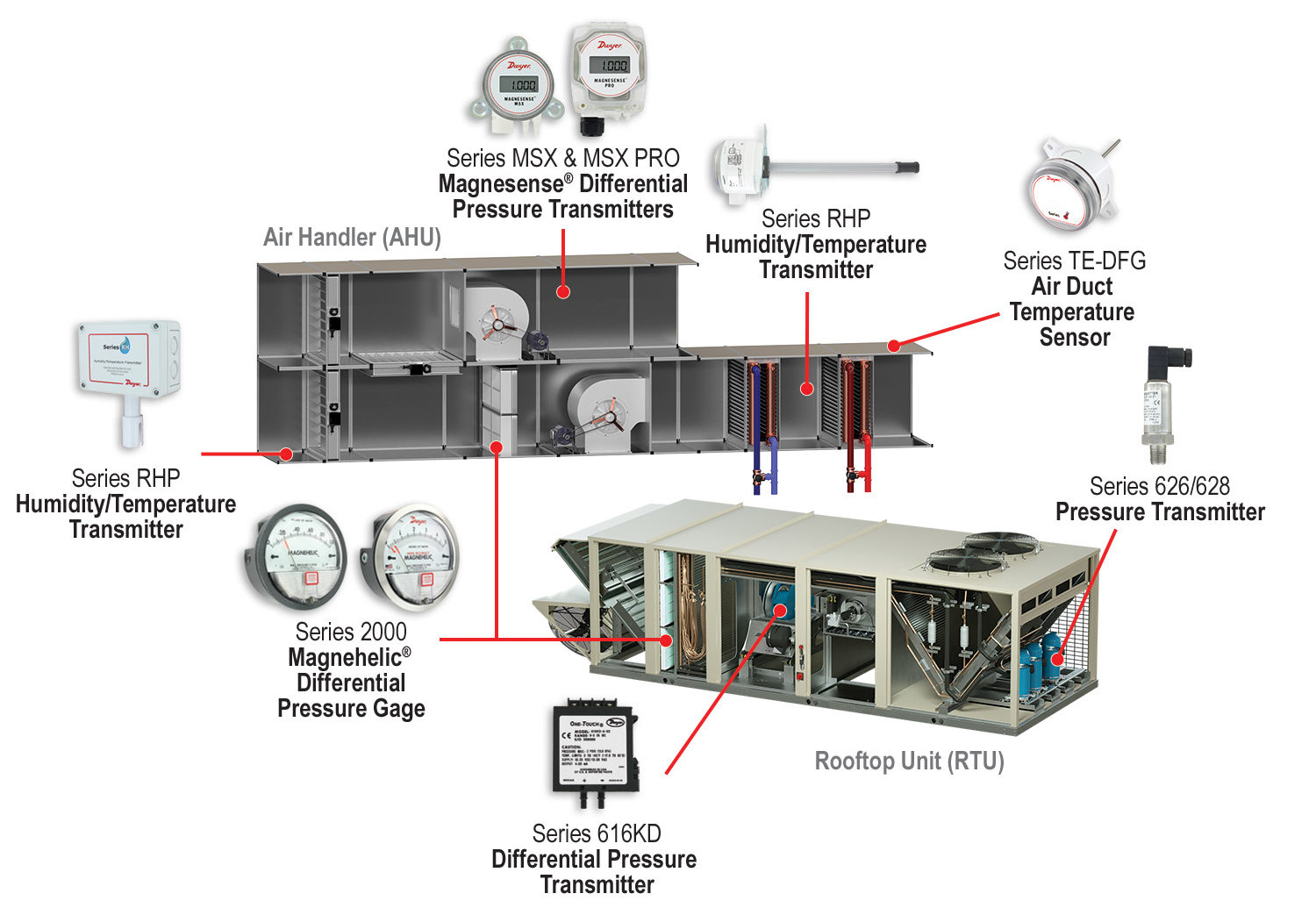

Imagine you sit down at a restaurant on the outdoor patio, and as you’re waiting to order your food, you glance at the large HVAC system on top of the building across the street. Several questions cross your mind: Why do they need such a big system? And what goes into it? Today I want to introduce one of the vital aspects of a building’s HVAC system, the air handler.

Imagine you sit down at a restaurant on the outdoor patio, and as you’re waiting to order your food, you glance at the large HVAC system on top of the building across the street. Several questions cross your mind: Why do they need such a big system? And what goes into it? Today I want to introduce one of the vital aspects of a building’s HVAC system, the air handler.