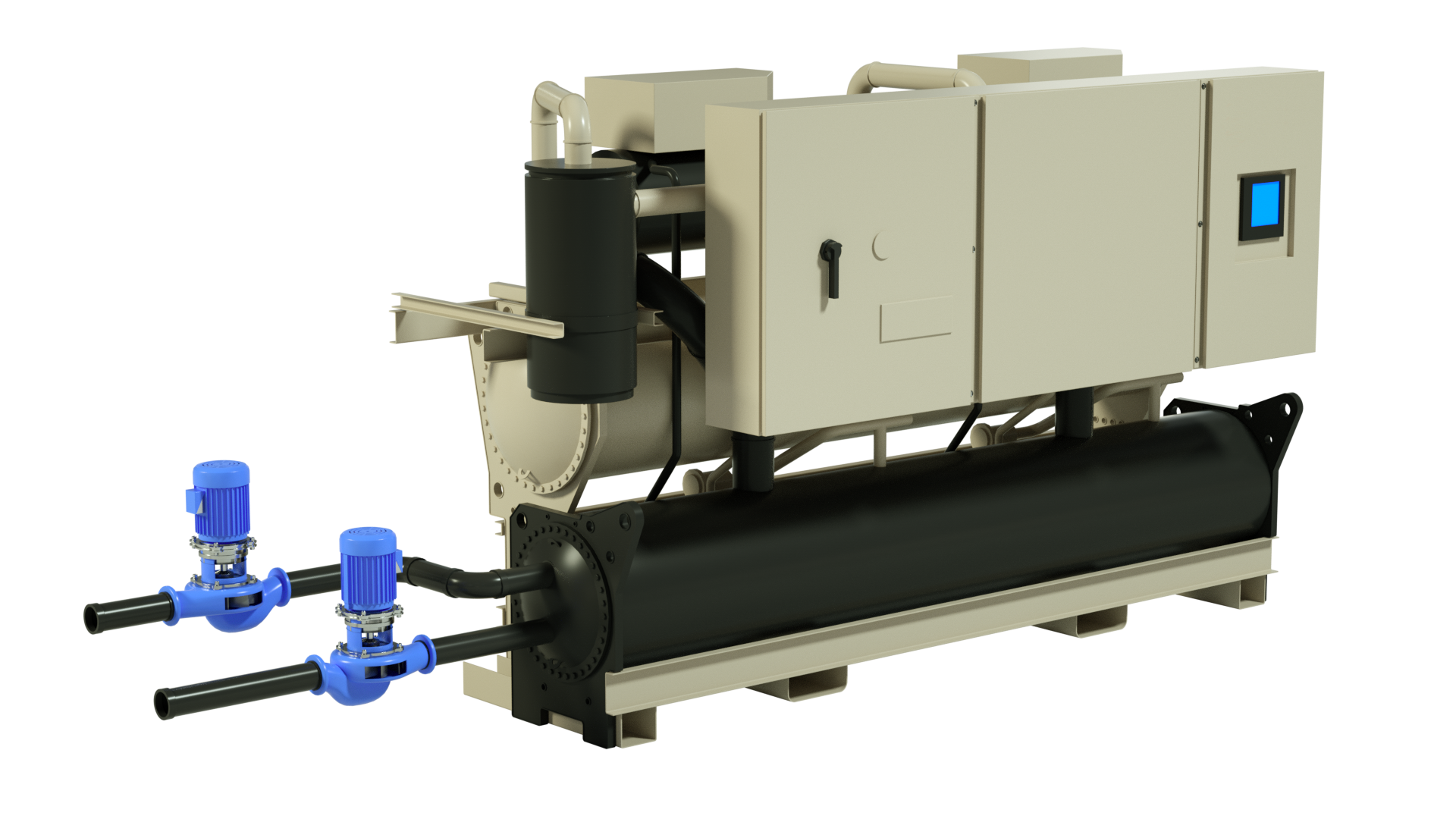

Water chillers are nothing new, with nearly an estimated 100,000 units operating in North America alone. Chillers are the cooling machines of choice to condition industrial, commercial, and institutional facilities. They are used to lower the temperatures of all kinds of equipment and processes such as: robotic machinery; semiconductors; injection and blow molding machines; welding equipment; die-casting and machine tooling; paper and cement processing; power supplies; power generation stations; compressed air and gas cooling systems; medical imaging machines; chemical, drug, food and beverage production; even simply to cool potable water to desirable levels. Whether for office comfort, keeping data server centers from overheating, or specialized industrial processes, water temperature control plays a vital role in many of the behind-the-scenes activities that affect our everyday lives. Continue reading “Proving Flow Through Chillers”

Water chillers are nothing new, with nearly an estimated 100,000 units operating in North America alone. Chillers are the cooling machines of choice to condition industrial, commercial, and institutional facilities. They are used to lower the temperatures of all kinds of equipment and processes such as: robotic machinery; semiconductors; injection and blow molding machines; welding equipment; die-casting and machine tooling; paper and cement processing; power supplies; power generation stations; compressed air and gas cooling systems; medical imaging machines; chemical, drug, food and beverage production; even simply to cool potable water to desirable levels. Whether for office comfort, keeping data server centers from overheating, or specialized industrial processes, water temperature control plays a vital role in many of the behind-the-scenes activities that affect our everyday lives. Continue reading “Proving Flow Through Chillers”

How to Program a Switch for Manual Reset

Several applications require manual reset switches, which are switches that need to be physically reset by an individual for a process to continue or restart. A manual reset is often needed when an area has to be inspected prior to equipment restart. This can help to ensure the safety/inspection of both equipment and other individuals in the area.

Some switches have a mechanical manual reset (such as the Dwyer Series 1900, 1831, and 1800). However, there may be a need to have a manual reset for applications beyond what these switches are designed for. If a pump is allowed to run with a clogged filter, for example, this may severely damage the pump. Continue reading “How to Program a Switch for Manual Reset”

Characteristics of Thermal Anemometers & Why They’re Well-Suited for Low Flow Applications

There are two common ways to measure air velocity: by using pressure-based instrumentation or by using temperature-based instrumentation. Before we discuss the different technologies available for measuring velocity pressure, it is important to understand the basics of air velocity.

How the Dwyer Series IEF and IEFB Overcome Typical Sources of Error

There are a wide variety of technologies that can be used for fluid flow measurement, such as differential pressure, paddlewheel, electromagnetic, and ultrasonic. Furthermore, each technology has multiple installation configurations. It is important to understand the nuances of different technologies and installations in order to pick the right flowmeter for your application.

There are a wide variety of technologies that can be used for fluid flow measurement, such as differential pressure, paddlewheel, electromagnetic, and ultrasonic. Furthermore, each technology has multiple installation configurations. It is important to understand the nuances of different technologies and installations in order to pick the right flowmeter for your application.

When purchasing a flowmeter for an HVAC application, such as boiler feed water monitoring or chilled/condenser water monitoring, we found that our customers value the ability to hot-tap (or pressure tap) a pipe to install an insertion flowmeter. This is done by installing an isolation valve in a pipe, allowing an insertion flowmeter to be placed into and removed from a live system without having to drain it. Draining a system is time consuming, costly, and generally not a good option for HVAC systems in buildings because it requires the entire system to be shut down. Permanently installing a hot-tap valve followed by an insertion flowmeter (with hot-tap capability) is an ideal alternative to a costly inline meter.

When considering an insertion flowmeter for an HVAC application, there are four key sources of error to be aware of: Continue reading “How the Dwyer Series IEF and IEFB Overcome Typical Sources of Error”

Certificates of Calibration Explained

Dwyer Instruments, Inc. offers a variety of calibration services for new or previously purchased products. In 2019, the Dwyer Instruments, Inc. – Engineering Laboratory, located in Michigan City, IN, gained accreditation to ISO/IEC 17025:2017 through the ANSI National Accreditation Board. The Dwyer lab now offers two different types of calibration certificates for our products: a certificate of NIST calibration and an ISO/IEC 17025:2017 accredited certificate of calibration. Now that accredited calibration services are available for select Dwyer products, it is important to know the differences between these two different calibration certificates. Knowing these differences will allow you to understand which calibration certificate will best suit your needs. Continue reading “Certificates of Calibration Explained”

Dwyer Instruments, Inc. offers a variety of calibration services for new or previously purchased products. In 2019, the Dwyer Instruments, Inc. – Engineering Laboratory, located in Michigan City, IN, gained accreditation to ISO/IEC 17025:2017 through the ANSI National Accreditation Board. The Dwyer lab now offers two different types of calibration certificates for our products: a certificate of NIST calibration and an ISO/IEC 17025:2017 accredited certificate of calibration. Now that accredited calibration services are available for select Dwyer products, it is important to know the differences between these two different calibration certificates. Knowing these differences will allow you to understand which calibration certificate will best suit your needs. Continue reading “Certificates of Calibration Explained”