Open channel flow monitoring is a method of measuring water flow rates in irrigation channels, streams, and storm water systems. It’s also used in wastewater processing for monitoring the effluent discharge. In most applications for open channel flow, weirs and flumes are used. For those of us not familiar, weirs and flumes concentrate the flow into a known cross sectional area, relating an accurate level reading to an accurate flow rate. The height of the water in the channel, going over the weir or flume, is directly proportional to the flow rate. Continue reading “Open Channel Flow Monitoring”

Open channel flow monitoring is a method of measuring water flow rates in irrigation channels, streams, and storm water systems. It’s also used in wastewater processing for monitoring the effluent discharge. In most applications for open channel flow, weirs and flumes are used. For those of us not familiar, weirs and flumes concentrate the flow into a known cross sectional area, relating an accurate level reading to an accurate flow rate. The height of the water in the channel, going over the weir or flume, is directly proportional to the flow rate. Continue reading “Open Channel Flow Monitoring”

Outside Air Humidity

This week is Air Quality Awareness Week, which is promoted by AirNow to discuss the importance of healthy air for everyone. One vital part of air quality involves monitoring humidity and temperature, so using an accurate outside humidity and temperature sensor can have a significant impact.

This week is Air Quality Awareness Week, which is promoted by AirNow to discuss the importance of healthy air for everyone. One vital part of air quality involves monitoring humidity and temperature, so using an accurate outside humidity and temperature sensor can have a significant impact.

Most air handling units (AHUs) use what is called an economizer cycle. This is when outside air is mixed with the return air to cool the building dependent upon the outside temperature. However, if the air is too dry and requires humidification to accomplish this process, your cost savings may have been eliminated due to the AHUs humidity control, which provides excessive steam for this humidification procedure to take place. Consequentially, sometimes based on weather conditions, your economizer may just be costing you money instead of saving it. Continue reading “Outside Air Humidity”

Manufacturing an Economic Dust Filtration System

Many customers have come to the Dwyer team asking: “What can Dwyer do to help with lean manufacturing?” In this article, we will discuss the Dwyer® Series SVT solenoid valve and timer enclosure and its cost savings advantages in a dust filtration system.

The Series SVT combines two integral components in a dust filtration system into one package: solenoid valves and a timer controller. In a dust filtration system, solenoid valves are used to send air through a pulse valve, such as our Series RDCS. Pulse valves release a quick spurt of air into a dirty dust cartridge filter, which, in turn, releases the dust from the filter. The timer portion of the dust filtration system is the brains of the operation controlling when the solenoids fire, the amount of time the solenoids are open, and when the next solenoid in the sequence fires. Continue reading “Manufacturing an Economic Dust Filtration System”

Parking Garage Ventilation Control

The Series GSTA carbon monoxide/nitrogen dioxide gas transmitters offer a robust, low cost alternative to standalone garage ventilation control packages.

As cities around the world continue to grow, the need for parking becomes an integral part of new commercial and municipal building plans. Many building designers are finding ways to offer adequate parking in a limited amount of real estate. Two emerging trends to do so are enclosed parking garages and mixed-use parking garages. Both of these designs seek to offer users a comfortable way to park their vehicles, all while being near their final destination. This means that the parking facility and the commercial or residential buildings are not separated, but are integrated together into one building structure. Due to this integration, two major concerns arise. How do we ventilate the harmful exhaust from the vehicles while being so close to the populated areas of the building, which require clean air and how do we accomplish this in the most energy efficient way possible? The Dwyer® Series GSTA carbon monoxide/nitrogen dioxide gas transmitters offer the sensory inputs necessary for any building automation system to answer this very quandary in an efficient and low cost manner. Continue reading “Parking Garage Ventilation Control”

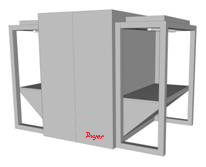

Downdraft Table Applications

There are many manufacturing processes that require human operators to perform tasks, which can create hazardous levels of particulate, fumes, gases, vapors, and mists. A few of these processes include: welding, sanding, grinding, brazing, laser cutting, tempering, and quenching. The Occupational Safety and Health Administration (OSHA) has regulatory requirements to reduce worker’s exposure to these hazards, which can cause respiratory and other health issues. Downdraft tables are workstations designed to better protect the operators who perform these tasks, in a bench top setting, by removing the hazardous material that laden the air from the worker’s breathing zone. Continue reading “Downdraft Table Applications”