The purpose of a clean room is to limit the number of particulates in a clean space. These particulates can be any type of sub-micron particles, such as dust, pathogens, chemical vapors, or moisture droplets. Clean room manufacturing areas are used by many industries to produce semiconductors, pharmaceuticals, medical devices, etc.

The purpose of a clean room is to limit the number of particulates in a clean space. These particulates can be any type of sub-micron particles, such as dust, pathogens, chemical vapors, or moisture droplets. Clean room manufacturing areas are used by many industries to produce semiconductors, pharmaceuticals, medical devices, etc.

Maintaining a proper differential pressure between the clean room and the exterior area is the most crucial aspect of keeping the clean room “clean”. To understand why sensor stability is important to these critical applications, it is important to also understand why a pressure difference is needed. Continue reading “Importance of Sensor Stability in Clean Rooms”

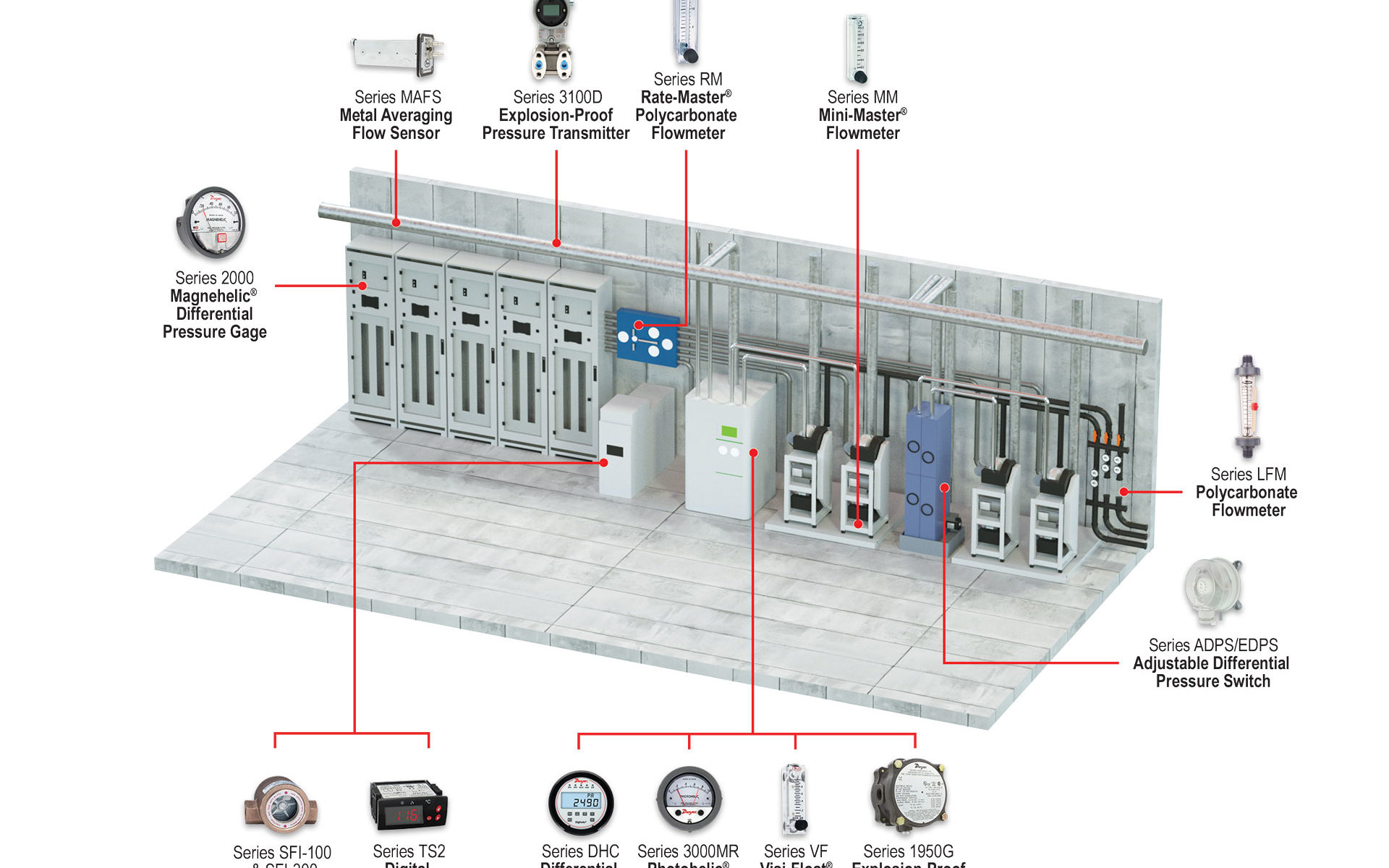

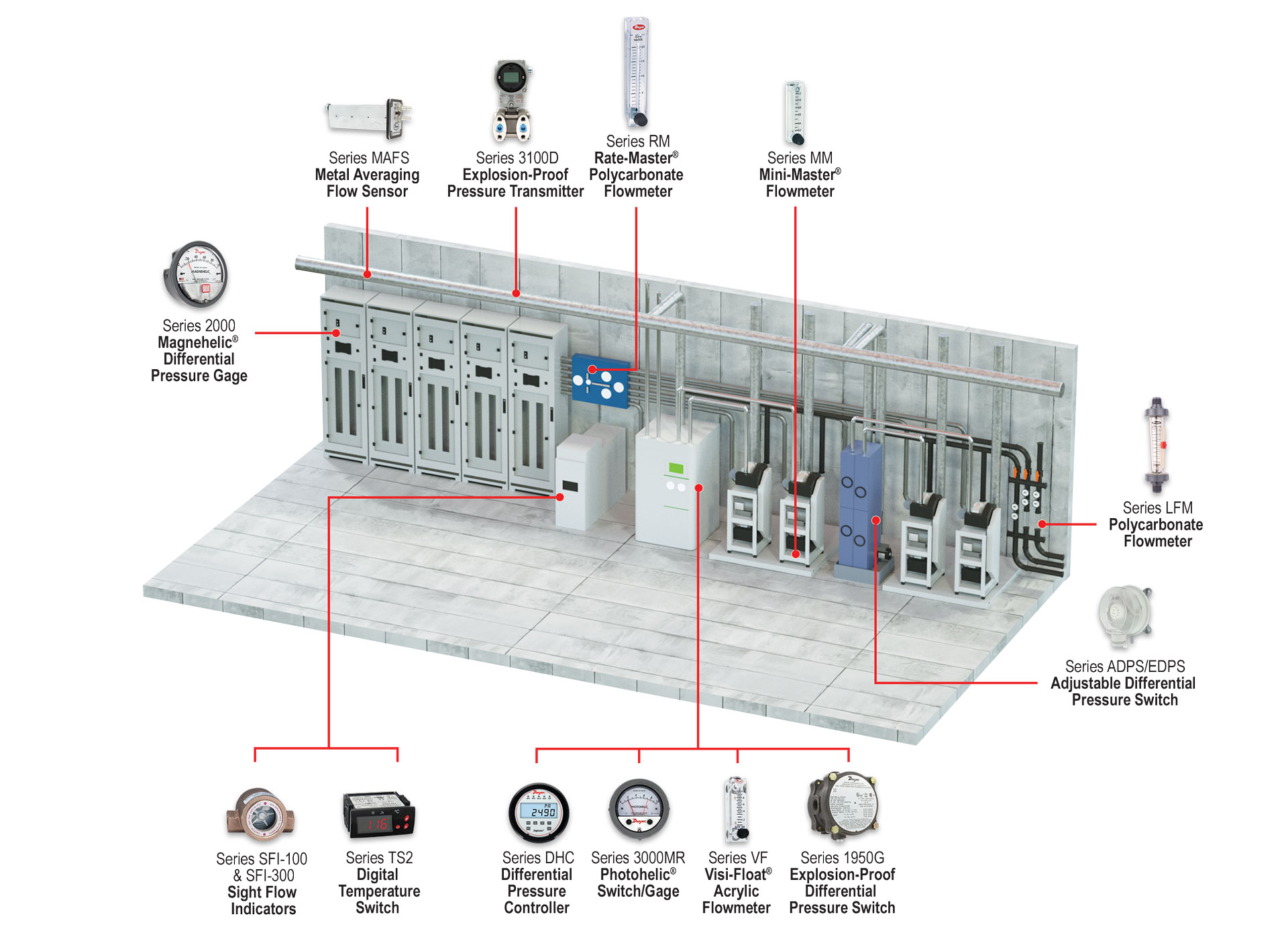

In the dynamic landscape of industrial instrumentation, every application has its unique demands. We want to ensure that our products meet your application needs. To do that, Dwyer Instruments provides not only a user-friendly online product configurator, but also a Fast Track Program for a fully customized solution.

In the dynamic landscape of industrial instrumentation, every application has its unique demands. We want to ensure that our products meet your application needs. To do that, Dwyer Instruments provides not only a user-friendly online product configurator, but also a Fast Track Program for a fully customized solution.

Thermal flowmeters use the thermal properties of the fluid to measure the flow of a fluid flowing in a pipe or duct. In a typical thermal flowmeter, a measured amount of heat is applied to the heater of the sensor. Some of this heat is lost to the flowing fluid. As flow increases, more heat is lost. The amount of heat lost is sensed using temperature measurement(s) in the sensor. The transmitter uses the heat input and temperature measurements to determine fluid flow. Most thermal flowmeters are used to measure gas flows. Thermal flowmeters represent 2% of global flowmeter sales.

Thermal flowmeters use the thermal properties of the fluid to measure the flow of a fluid flowing in a pipe or duct. In a typical thermal flowmeter, a measured amount of heat is applied to the heater of the sensor. Some of this heat is lost to the flowing fluid. As flow increases, more heat is lost. The amount of heat lost is sensed using temperature measurement(s) in the sensor. The transmitter uses the heat input and temperature measurements to determine fluid flow. Most thermal flowmeters are used to measure gas flows. Thermal flowmeters represent 2% of global flowmeter sales.