In many industrial processes, the materials and the end product or by-products  of the process, such as dust or vapors, can create conditions for a hazardous environment. Processes that have potential for hazardous environments include: water treatment, oil drilling, gas and chemical processing, power generation, pharmaceutical, and food manufacturing. The measurement and control of these processes are essential in maintaining optimal conditions of the manufacturing system and preventing catastrophic events. Continue reading “The Operation of Gages and Switches in Hazardous Environments”

of the process, such as dust or vapors, can create conditions for a hazardous environment. Processes that have potential for hazardous environments include: water treatment, oil drilling, gas and chemical processing, power generation, pharmaceutical, and food manufacturing. The measurement and control of these processes are essential in maintaining optimal conditions of the manufacturing system and preventing catastrophic events. Continue reading “The Operation of Gages and Switches in Hazardous Environments”

Product Highlight: Series MSX Pro Magnesense® Differential Pressure Transmitter

The Dwyer team recently released the Series MSX Pro Magnesense® Differential Pressure Transmitter, which meets stringent industry standards with innovative global product design. This series is ideal for monitoring building control applications, and also utilizes enhanced accuracy and stability for use in high performance, critical environments. Continue reading “Product Highlight: Series MSX Pro Magnesense® Differential Pressure Transmitter”

The Dwyer team recently released the Series MSX Pro Magnesense® Differential Pressure Transmitter, which meets stringent industry standards with innovative global product design. This series is ideal for monitoring building control applications, and also utilizes enhanced accuracy and stability for use in high performance, critical environments. Continue reading “Product Highlight: Series MSX Pro Magnesense® Differential Pressure Transmitter”

Downdraft Table Applications

There are many manufacturing processes that require human operators to perform tasks, which can create hazardous levels of particulate, fumes, gases, vapors, and mists. A few of these processes include: welding, sanding, grinding, brazing, laser cutting, tempering, and quenching. The Occupational Safety and Health Administration (OSHA) has regulatory requirements to reduce worker’s exposure to these hazards, which can cause respiratory and other health issues. Downdraft tables are workstations designed to better protect the operators who perform these tasks, in a bench top setting, by removing the hazardous material that laden the air from the worker’s breathing zone. Continue reading “Downdraft Table Applications”

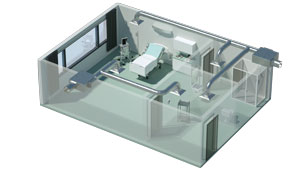

What are Room Pressure and Room Status Monitors?

Differential pressure between two rooms prevents dust, particulates, and pathogens from entering or exiting one room and going into the other. Depending on the relationship between rooms, one room will be under positive pressure when referenced against the other. This positive-negative pressure relationship between two spaces is the main idea behind clean rooms and isolation rooms. To ensure the differential pressure relationship is maintained, a measuring device must be used.

Room pressure monitors and room status monitors measure, display, and transmit the differential pressure reading between two rooms. In general, room pressure monitors only monitor differential pressure. On the other hand, room status monitors monitor differential pressure and additional parameters such as relative humidity, temperature, air change, or door status. They are both used in critical applications that require critical low differential pressure relationships. Continue reading “What are Room Pressure and Room Status Monitors?”

Importance of Sensor Stability in Healthcare Isolation Rooms

The purpose of a healthcare isolation room is to prevent patients with contagious illnesses from spreading to others or to keep immunocompromised patients safe from exposure to airborne pathogens. As such, there exist two types of isolation rooms, either positively or negatively pressurized.

Positive pressure isolation rooms are designed to keep pathogens and outside air from entering the room, i.e. air inside the room is forced outward and is typically used for immunocompromised patients. Like clean rooms, it is important to maintain proper positive pressure within the protective isolation room to keep the patients safe. Continue reading “Importance of Sensor Stability in Healthcare Isolation Rooms”