There are a wide variety of technologies that can be used for fluid flow measurement, such as differential pressure, paddlewheel, electromagnetic, and ultrasonic. Furthermore, each technology has multiple installation configurations. It is important to understand the nuances of different technologies and installations in order to pick the right flowmeter for your application.

There are a wide variety of technologies that can be used for fluid flow measurement, such as differential pressure, paddlewheel, electromagnetic, and ultrasonic. Furthermore, each technology has multiple installation configurations. It is important to understand the nuances of different technologies and installations in order to pick the right flowmeter for your application.

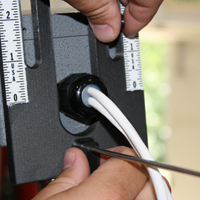

When purchasing a flowmeter for an HVAC application, such as boiler feed water monitoring or chilled/condenser water monitoring, we found that our customers value the ability to hot-tap (or pressure tap) a pipe to install an insertion flowmeter. This is done by installing an isolation valve in a pipe, allowing an insertion flowmeter to be placed into and removed from a live system without having to drain it. Draining a system is time consuming, costly, and generally not a good option for HVAC systems in buildings because it requires the entire system to be shut down. Permanently installing a hot-tap valve followed by an insertion flowmeter (with hot-tap capability) is an ideal alternative to a costly inline meter.

When considering an insertion flowmeter for an HVAC application, there are four key sources of error to be aware of: Continue reading “How the Dwyer Series IEF and IEFB Overcome Typical Sources of Error”

We recently met with a customer in India who needed to replace a flowmeter in an Energy Monitoring System (EMS) application in a commercial shopping mall.

We recently met with a customer in India who needed to replace a flowmeter in an Energy Monitoring System (EMS) application in a commercial shopping mall.