Have you ever noticed that some pressure sensors have units listed in PSIG  while others list PSIA? There are numerous applications where pressure sensors are used and some applications require a different reference to ensure the most accurate pressure measurement.

while others list PSIA? There are numerous applications where pressure sensors are used and some applications require a different reference to ensure the most accurate pressure measurement.

PSIA, also known as pounds per square inch absolute, is defined as pressure measured relative to absolute zero or full vacuum. Because the baseline of the sensor is absolute zero, the sensor will not be affected by altitude changes or temperature changes. This is typically accomplished in the manufacturing process by sealing a high vacuum behind the pressure sensing diaphragm. When the process connection port is open or exposed to atmospheric air, the sensor will read the actual barometric pressure which can be affected by elevation and temperature.

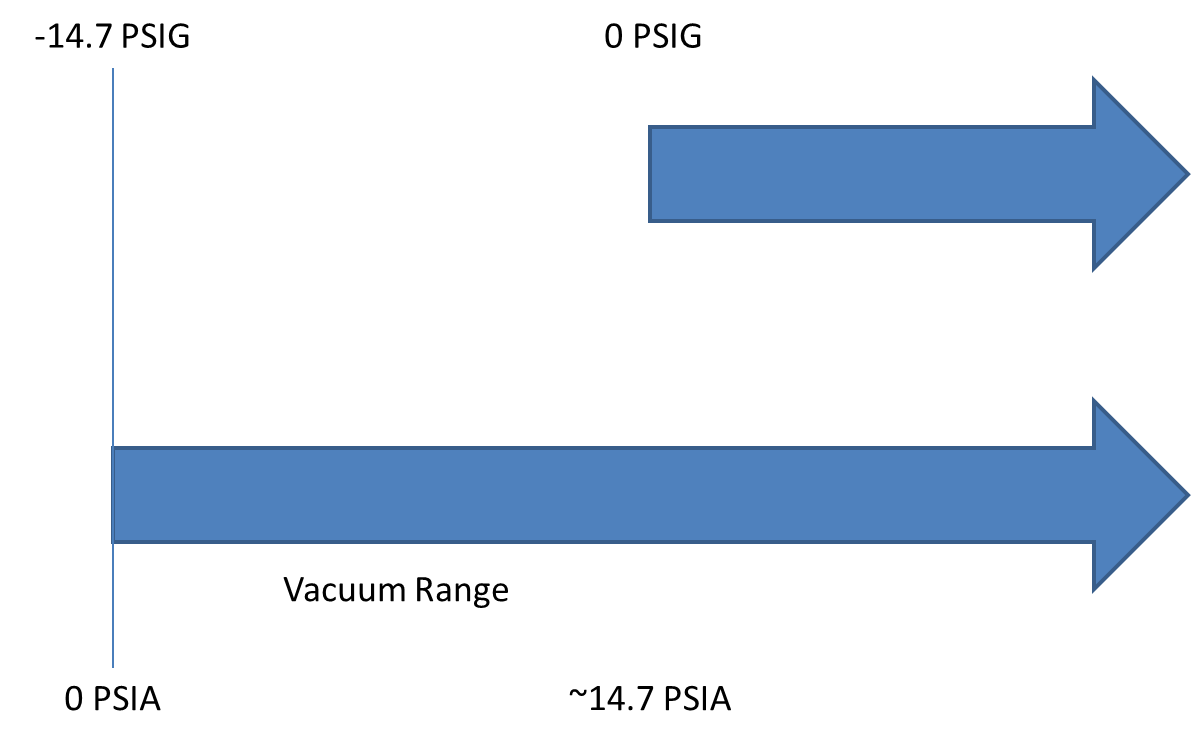

PSIA differs greatly from PSIG, pounds per square inch gauge, which uses atmospheric pressure as its reference pressure and is measured relative to current barometric pressure. In most gauge pressure sensors, ambient air (or the reference air) is passed through a vent tube or hole to the back side of the pressure sensing element. This explains why a pressure sensor will read zero when the process connection port is open or exposed to atmospheric air. Figure 1, shown below illustrates the difference between PSIA and PSIG.

What types of applications might you see an absolute pressure sensor used in? One of the most common applications is in outdoor weather stations for weather forecasting and predictions. Other applications include HVAC/HVACR refrigeration systems, semi-conductor equipment and manufacturing processes, aviation or aeronautical equipment, irrigation equipment, or gas analysis systems.

If you have any questions about selecting products for your application, the DwyerOmega Applications Engineers are available to assist by phone at (219) 879-8868 x6402, or by email at tech@dwyeromega.com.

To learn about or order any Dwyer products, please visit our website: https://www.dwyer-inst.com/

To learn more about pressure types, click here.