Hi-Flow™ control valves are single seated, top or cage guided globe valves – probably the simplest, from a construction standpoint, yet most versatile control valve in use. The Hi-Flow™ valve can fit applications with a smaller size valve since the valve has a greater flow capacity than most conventional valves of the same size. Coupled with a high flow capacity, the Hi-Flow™ valve maintains a wide rangeability of 50:1 to ensure precise control.

Heavy duty Hi-Flow™ valves are ruggedly constructed of the highest quality materials, precision machined, and performance tested to assure years of trouble free service. Standard packing consists of PTFE V-rings and wiper to minimize friction without leakage at high operating pressures. Available in brass, iron, or 316 SS body, trim is 316 SS with all welded plug construction to provide superior durability and corrosion resistance.

Our Hi-Flow™ control valves were originally designed and manufactured by Taylor, and are well known as a durable and dependable valve. Dwyer Instruments, Inc. acquired the Hi-Flow™ line in 1991 and has continued manufacturing this great quality valve under the W.E. Anderson division.

FEATURES/BENEFITS

- Wide rangeability of 50:1

- Exceptional shut-off and leak rate that meets ANSI/FCI 70-2 Class IV (0.01% of Cv in the closed position)

- Selectable fail-safe condition with air-to-raise or air-to-lower actuators and push-to-open or push-to-close valve bodies

- Linear or equal percentage flow characteristics

- Low flow options of restricted trim or needle plug

- Removable and replaceable seat ring

APPLICATIONS

- Flow control, mixing, or diverting service

- Perfect for steam, water, or compatible glycol solutions

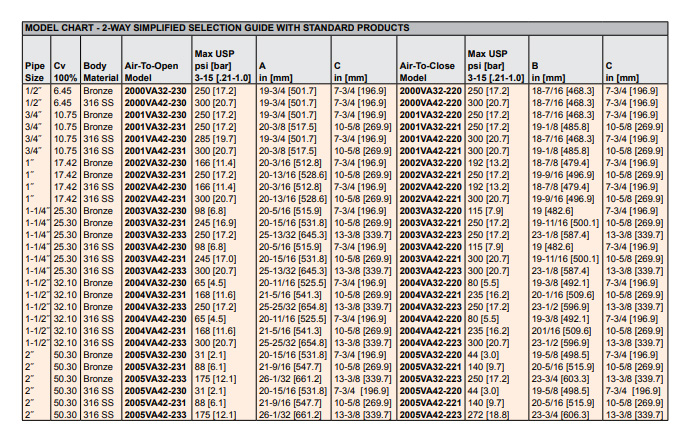

Featured at the bottom of this article is a model chart, which shows simplified selection options with standard models for both 2-way & 3-way valves. You may also visit our product configurator or call 1-844-372-5551 for non-standard options such as factory mounted positioners, current to pressure transducers or calibration to your specific upstream pressure (USP) requirements.