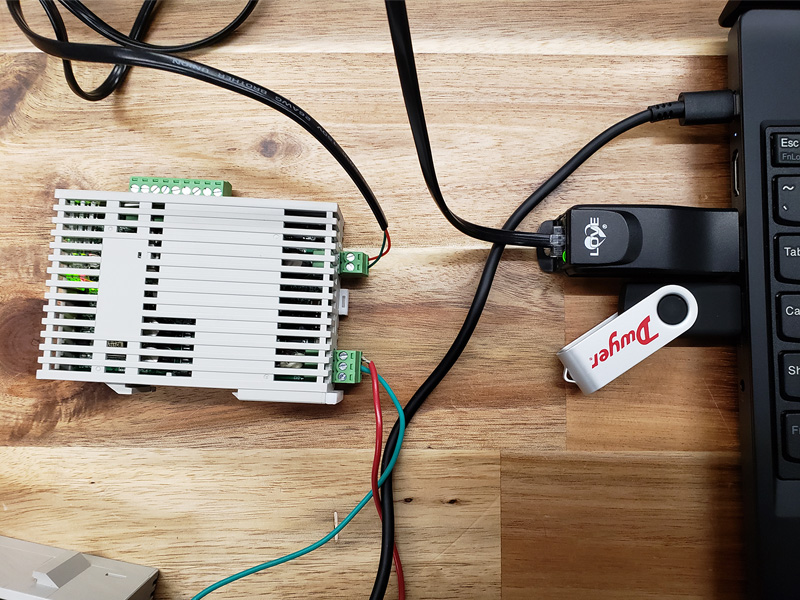

The Dwyer team is proud to announce the new app for the SMART Air Hood® balancing instrument. This app replaces the PredictAir™ application software, and ensures that connecting to your hood and balancing a building is now easier than ever!

The automated connection process within the app will prompt you to connect the SMART Air Hood® balancing instrument the first time you open it. Continue reading “Introducing the New App for the SMART Air Hood® Balancing Instrument”

The

The

We met with an original equipment manufacturer (OEM) last year, who was working on a new design for rooftop air handling equipment. Part of the their design utilized water flow for cooling in a loop.

We met with an original equipment manufacturer (OEM) last year, who was working on a new design for rooftop air handling equipment. Part of the their design utilized water flow for cooling in a loop.