As standards become stricter for monitoring indoor air quality (IAQ) it is important to understand that the readings from your instrumentation are correct and accurate. When monitoring carbon dioxide levels for on-demand ventilation, it is imperative that you account for barometric pressure as it can create a false sense of accuracy when controlling an HVAC system.

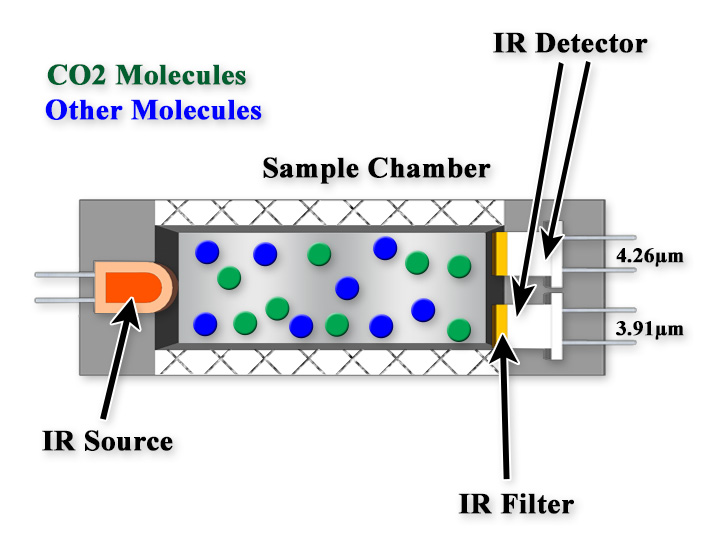

Dwyer Instruments, Inc. offers a variety of carbon dioxide sensors that can be used for monitoring space carbon dioxide levels, duct carbon dioxide levels, or a combination of humidity, temperature, and carbon dioxide levels. The Dwyer Series CDT, CDTR, and CDTV all incorporate non-dispersive infrared (NDIR) sensing technology. In a NDIR sensor, infrared light shines through a sample of carbon dioxide gas in a sample chamber. On the other side of the chamber, photo-detectors are used to measure the intensity of the infrared light shining through the CO2 sample. The photo-detectors are tuned to measure a specific wavelength of ~4.3 microns, which is the value of wavelength of CO2. This leads to a measurement of only CO2 while other gases, which have varying wavelengths, are not measured or detected. As more CO2 molecules become present, the infrared light is diminished when passing through the sample. By measuring the resultant light intensity, the instrument is able to determine the number of carbon dioxide molecules present.

When using an NDIR sensor, the sampling chamber is a fixed size and open to the environment or space to allow for air to move freely in and out of the sampling chamber. Since the discovery and development of the Ideal Gas Law, it is known that the number of air molecules in a given volume is affected by temperature and air pressure. The volume of air necessary to contain one million air molecules is affected by air temperature and air pressure (barometric pressure). As the barometric pressure decreases, the volume needed increases but is controlled by the size of the sampling chamber.

At low pressures, fewer air molecules will be in the sample chamber which results in fewer CO2 molecules; however, the concentration of CO2, measured in PPM (parts per million), will not change. With less CO2 molecules present, the NDIR sensor believes that the CO2 concentration is lower than it really is. The exact opposite occurs when at high pressures. More air molecules are contained in the sample chamber resulting in the sensor believing that the CO2 concentration is higher than it really is.

Using the Ideal Gas Law, we are able to determine that CO2 concentration can vary by up to 349 ppm when referencing ideal conditions; 77OF and 1,000 ppm CO2 at sea level.

| Altitude (ft) | Barometric Pressure (in Hg) | CO2 Concentration (ppm) |

| -1000 | 31.02 | 1,037 |

| 0 | 29.92 | 1,000 |

| 1,000 | 28.85 | 964 |

| 2,000 | 27.82 | 930 |

| 3,000 | 26.82 | 896 |

| 4,000 | 25.84 | 864 |

| 5,000 | 24.90 | 832 |

| 6,000 | 23.98 | 801 |

| 7,000 | 23.09 | 772 |

| 8,000 | 22.23 | 743 |

| 9,000 | 21.39 | 715 |

| 10,000 | 20.58 | 688 |

The Dwyer Series CDT, CDTR, and CDTV Temperature Transmitters offer a barometric pressure compensation setting in the programming of each instrument. This setting can be found in the setup and programming menus of the products. A number of elevations have already been pre-configured in these carbon dioxide sensors. By properly configuring your carbon dioxide sensor, you can see improved accuracy of your indoor air quality; especially when working on projects found at high elevations.