Proper selection and use of relative humidity (RH) sensors are important factors in designing and building a reliable, economical HVAC system. Over the years humidity control has been getting even greater attention because of its positive impact on indoor air quality (IAQ).

The importance of humidity measurement and control can mean different things depending on the application. To the museum curator, it means preserving valuable artwork and artifacts. To the hospital facilities engineer, it means a comfortable environment for the patients, as well as maintaining accurate moisture control to prevent the spread of bacteria and infection. And to the building maintenance professional, it means a reliable building automation system that reduces energy costs while increasing the comfort of its occupants.

RH SENSOR / TRANSMITTER SELECTION

Each application should be carefully analyzed before sensor selection to ensure the device will meet all necessary requirements. The most important questions to ask are:

What RH range do you need to measure?

Each manufacturer uses a unique sensor element. The most commonly used technologies today are capacitive and bulk polymer resistive. In basic commercial applications, either sensor technology will most likely meet your needs. However, each of these sensor technologies have advantages and disadvantages. If you know that you need a fast response time to changes in humidity, high-resistance to surface contamination, or repeatable readings at high humidity levels (>95% RH), please check with the manufacturer to ensure that the sensor will perform properly.

Are any chemicals or contaminants present?

Because each sensor has its own strengths and weaknesses with certain chemical agents, identifying and comparing a list of all chemicals and their concentration to the manufacturer’s contamination compatibility chart is extremely helpful. This will not only help you select the proper sensor, but it will also help in determining the sensor’s life and the best location for mounting. An example of where this would be important is in a swimming pool application where chlorine vapors are present.

What accuracy is required (1%, 2%, 3%, or 5%)?

Depending on the application, accuracy may be crucial or it may not be as important. Why spend more for a highly accurate transmitter (1% or 2%) if it’s simply being installed in a return air duct for commercial-grade monitoring? It is more important to have a higher degree of accuracy in precise control environments such as labs or hospitals. Over-specifying the accuracy can cost more and may not make the system any more efficient. Make a prudent choice based on how critical the system really is.

What drift rate can I accept (1% or 5% per year)?

Drift is inherent to all RH sensors, and it occurs over time due to a shift in the sensor characteristics, regardless of the manufacturer. Always select a transmitter with a low drift value (less than 1% per year).

What is the temperature range?

Is the unit being installed in a room where temperature ranges are typically narrow, or is it being placed in a duct or outdoor application where it may see wider temperature ranges? Consider the extremes before making a choice.

Is the unit temperature compensated?

All RH transmitters are affected by temperature that many manufacturers compensate for in the circuitry. This is usually labeled as “Temperature Effect” and is expressed as a percentage per °F or °C. Since most transmitters are factory-calibrated at 77°F (25°C), select a product that has a minimal (low) temperature effect value. This will help ensure RH accuracy at high and low probe temperatures.

How does the manufacturer calibrate the transmitter? Is it NIST traceable?

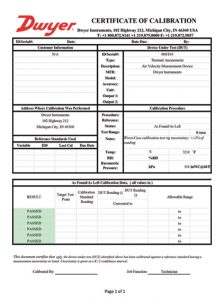

This varies from manufacturer to manufacturer. Many companies perform a manual calibration at only three RH values (low, medium, and high or 30%, 50%, and 80%) Others use sensors that are digitally calibrated at numerous RH and temperature values. The best that can be said of a transmitter is that it is digitally calibrated at multiple RH values against a NIST (National Institute of Standards and Technology) traceable standard. This ensures complete accuracy over the entire measurement range.

To learn about Dwyer’s calibration services, please visit our website.

Can the transmitter be recalibrated in the field?

Due to drift, the quality of the product, and the environment in which it is used, a transmitter may need to be either recalibrated or replaced. Costs associated with recalibration are often overlooked when selecting an RH transmitter. These costs can easily outweigh the original purchase price if not considered on the front end. Handheld instruments used to check the reading of a sensor do not require a lot of labor, but can cost more and also need annual recalibration. Remember, calibrating a product with an inaccurate reference device only exacerbates the problem and usually ends up costing more in the end.

By answering these questions for each application in which a humidity sensor is required, you can ensure proper operation and maximize the purchase and maintenance costs of the RH transmitter.

Dwyer carries a wide selection of humidity sensors for a variety of applications. From wall, duct and outdoor air mountings, Dwyer has a relative humidity sensor to meet your needs.