A semiconductor transistor is a part with specific electronic properties that allow it to serve as a component in microchips and modern electronics like phones, laptops, and more. As these components are small and require precise manufacturing methods, there are facilities dedicated to their manufacture.

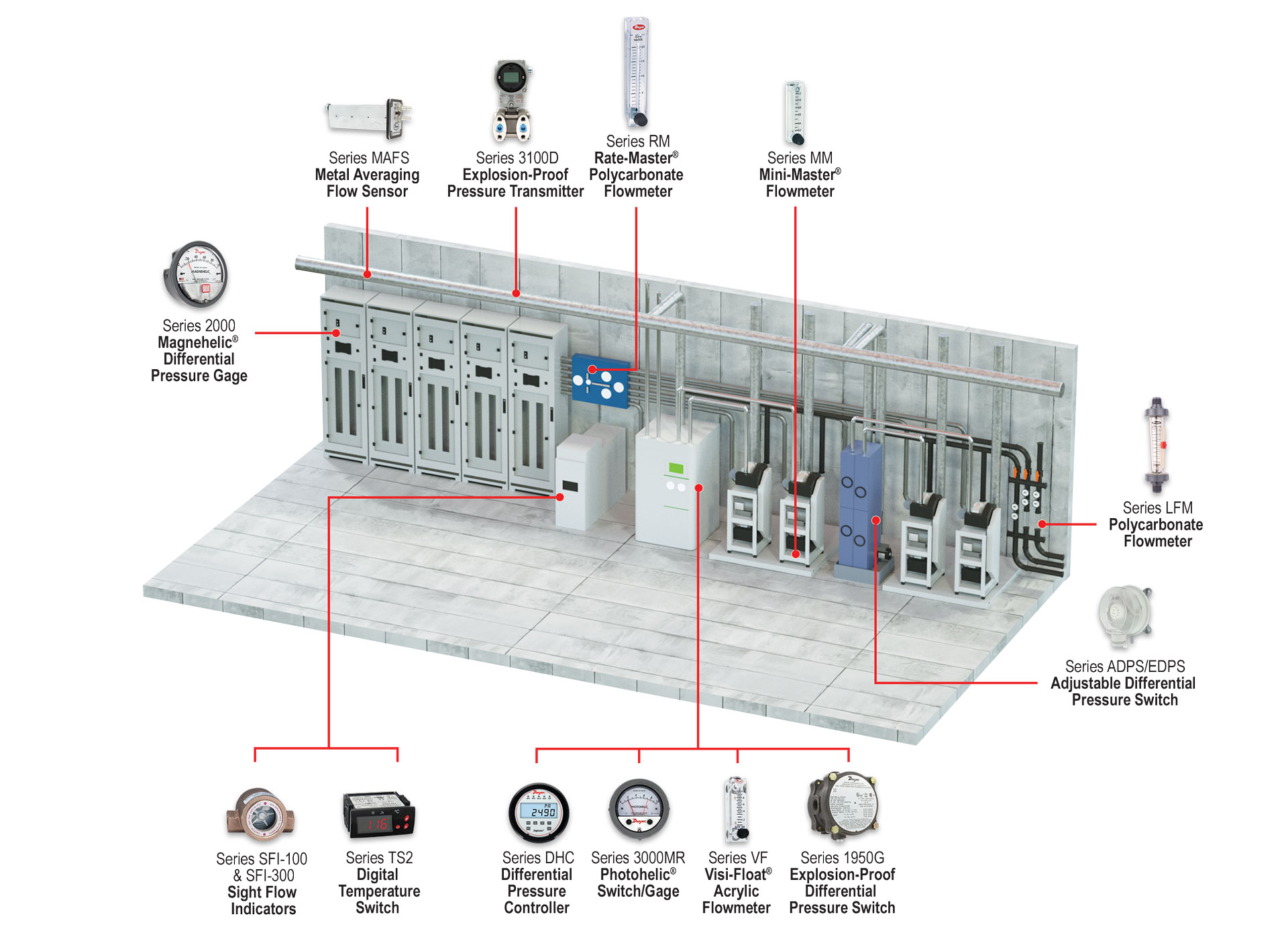

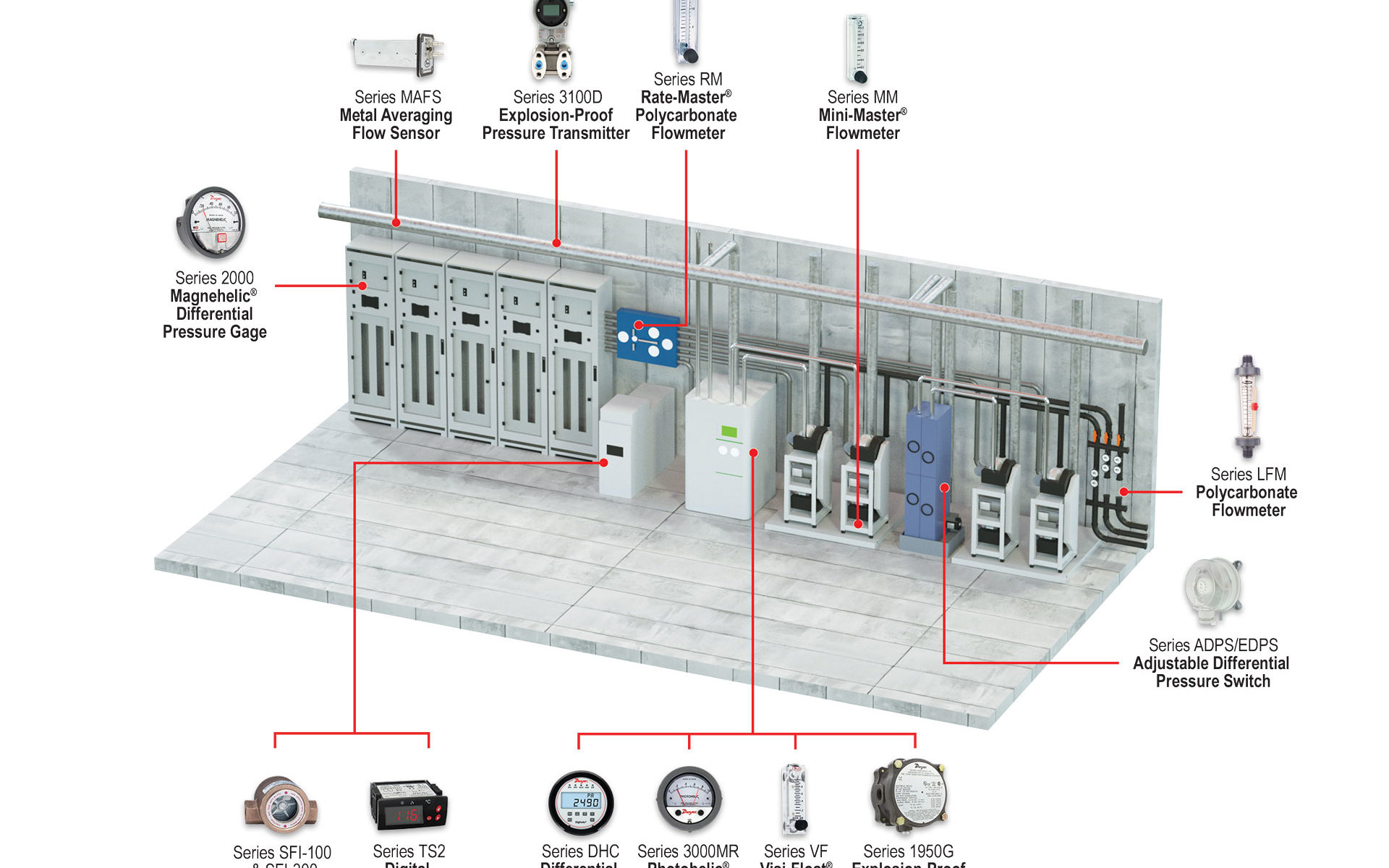

These facilities consist of several levels including air handlers and scrubbers for exhaust, HEPA room, fab cleanroom, and subfab areas. The control of pressure, flow, and temperature within the facility is essential.

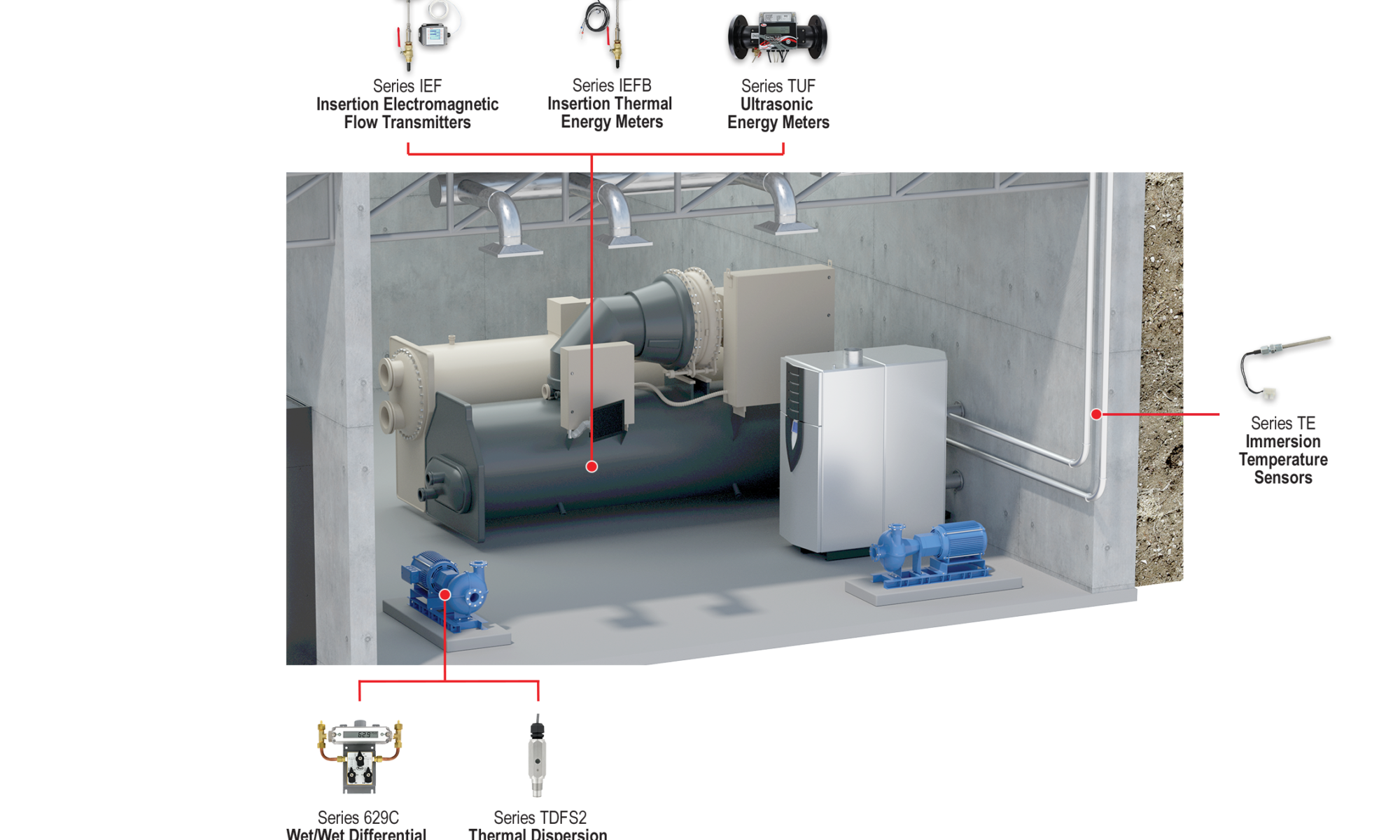

Semiconductor subfabs are located directly below the cleanroom. Here you will find an array of ancillary equipment, such as vacuum pumps, abatement systems, chillers, gas cabinets, and other equipment to keep process tools functioning efficiently. The equipment within the subfab is interconnected with the tools found within the fab cleanroom itself; these separate but connected areas work together to make sure the facility runs smoothly. Continue reading “Monitoring Solutions for Semiconductor Subfabs”

We talk a lot on this blog about the importance of indoor air quality in schools to boost students’ well-being. Also important to the school building is ensuring that the building is energy efficient – the dollars saved by reducing energy consumption can be used to further improve school facilities and enhance students’ learning environments.

We talk a lot on this blog about the importance of indoor air quality in schools to boost students’ well-being. Also important to the school building is ensuring that the building is energy efficient – the dollars saved by reducing energy consumption can be used to further improve school facilities and enhance students’ learning environments.

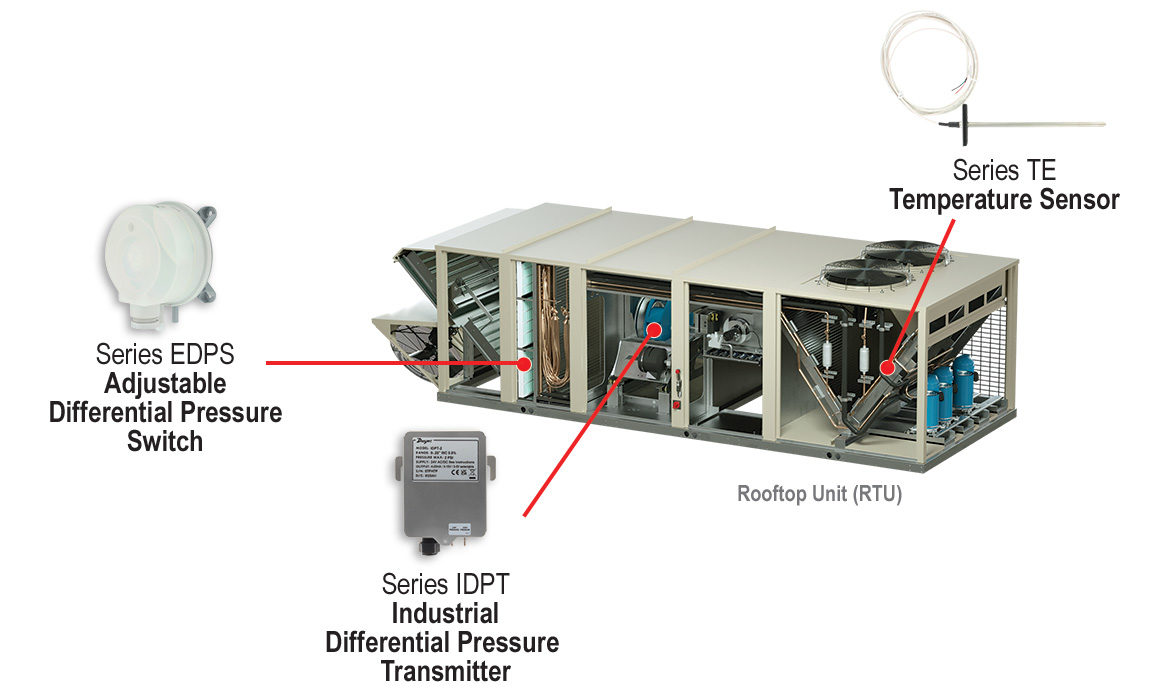

The HVACR industry is evolving to create more energy efficient and sustainable ways to cool our homes and commercial buildings using eco-friendly refrigerants that are less damaging to the environment, but significantly more flammable than their predecessors. The UL standard 60335 aims to balance these greener refrigerants while still maintaining occupancy safety as it applies to “packaged air conditioners and heat pumps; partial units; liquid chillers and hydronic fan coil units; hot water heat pumps; dehumidifiers; supplemental heaters and equipment with flammable refrigerants

The HVACR industry is evolving to create more energy efficient and sustainable ways to cool our homes and commercial buildings using eco-friendly refrigerants that are less damaging to the environment, but significantly more flammable than their predecessors. The UL standard 60335 aims to balance these greener refrigerants while still maintaining occupancy safety as it applies to “packaged air conditioners and heat pumps; partial units; liquid chillers and hydronic fan coil units; hot water heat pumps; dehumidifiers; supplemental heaters and equipment with flammable refrigerants