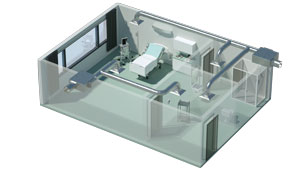

Differential pressure between two rooms prevents dust, particulates, and pathogens from entering or exiting one room and going into the other. Depending on the relationship between rooms, one room will be under positive pressure when referenced against the other. This positive-negative pressure relationship between two spaces is the main idea behind clean rooms and isolation rooms. To ensure the differential pressure relationship is maintained, a measuring device must be used.

Room pressure monitors and room status monitors measure, display, and transmit the differential pressure reading between two rooms. In general, room pressure monitors only monitor differential pressure. On the other hand, room status monitors monitor differential pressure and additional parameters such as relative humidity, temperature, air change, or door status. They are both used in critical applications that require critical low differential pressure relationships.

Historically, differential pressure manometers and gages were used to monitor pressure between rooms. In some cases, other types of verification have included monitoring air flow. Because the air flows from the high-pressure space to the low-pressure space, a positive/negative pressure relationship could be verified by monitoring the air flow. Over time, more sophisticated building automation systems (BAS) have been developed, necessitating upgrades from a simple gage to room monitors that tie back to a BAS controller.

Room Pressure Monitors and Room Status Monitors

Room pressure monitors are devices that measure differential pressure between the isolation room or clean room and the anteroom (small room just outside the critical room). They communicate with a BAS system through an analog output (4-20 mA, 0-5 V, etc.) or BACnet or Modbus® communication. The BAS system will then adjust the amount of air being provided to the clean room or isolation room in order to keep it at the desired differential pressure between the anteroom.

Room pressure monitors typically only provide pressure measurement, indication, and alarm features. However, they may also include a door switch input to alert staff when a door has been left open for too long.

Room status monitors monitor pressure differential between anterooms and isolation rooms or clean rooms as well, but also they provide additional functionality. Room status monitors not only monitor pressure; they are capable of monitoring additional room variables such as air change per hour (ACH), relative humidity, temperature, door status, and additional room pressures.

Since room status monitors are capable of monitoring more than one differential pressure measurement, they can monitor multiple rooms simultaneously. Room status monitors take input from either analog or BACnet sensors to display and alarm these additional parameters.

Both room status monitors and room pressure monitors can have audible alarms, LCD screen color changes, LED status indication, edge light status indication, or a combination of status light and sound alerts to indicate the room condition.

Here is a comparison of the differences between room pressure monitors and room status monitors:

| Criteria | Room Pressure Monitors | Room Status Monitor |

| Pressure Monitoring | ✔ | ✔ |

| Additional Parameter Monitoring | X | ✔ |

| Multi-room Monitoring | X | ✔ |

| Status Light Indication | ✔ | ✔ |

| Audible Alarming | ✔ | ✔ |

| BAS Communication | ✔ | ✔ |

| LCD touchscreen | X | ✔ |

| Common Applications | Pharmaceutical & Semiconductor manufacturing, healthcare | Healthcare applications, AIIRs, ORs, pharmaceutical areas |

Where are Room Monitors Used?

Room pressure and room status monitors, sometimes grouped together with the term “room monitors”, are both used in critical applications requiring low-pressure monitoring. The applications commonly include:

- Semiconductor manufacturing areas

- Pharmaceutical manufacturing and compounding areas

- Hospital isolation rooms (airborne infection isolation rooms – AIIR)

- Clean rooms

- Dental offices

- School nurses offices

In fact, with recent world events, both room pressure monitors and room status monitors are becoming increasingly more common in healthcare settings. The ASHE (American Society of Healthcare Engineers) guide, Health Care Facilities Ventilation Controls and Guidelines for Management of Patients with Suspected or Confirmed SArRS-CoV-2 (COVID-19), provides recommendations for airborne infection isolation rooms.

In their recommendations, ASHE states that AIIRs must be under negative pressure and meet 6-12 air changes per hour depending on the building design and room criteria. Additionally, the isolation rooms should exhaust through a HEPA filter if recirculated or to unoccupied areas outside of the healthcare facility.

Additionally, ASHRAE’s Standard 170, Ventilation of Health Care Facilities provides guidelines to follow CDC design requirements for airborne infection isolation rooms (AII or AIIR):

- Use of negative pressure rooms with close monitoring of air flow direction using manometers or temporary or installed visual indicators placed in the room with the door closed

- Negative pressure room engineering features include negative pressure

- Pressure differential of 2.5 Pa (0.01 inches of water column)

- Minimum of 6 ACH (air changes per hour) for existing facilities, greater than or equal to 12 ACH for areas under renovation or for new construction

- Air from negative pressure rooms and treatment rooms exhausted directly to the outside if possible

These design requirements can be met by the use of room status monitors that are tied in with peripheral sensors measuring pressure, air flow, or humidity in the airborne infection isolation room.

Lastly, ASHRAE’s guidelines for the safe reopening of schools provide new design requirements for educational facilities. The new design requirements apply to new buildings and retrofits. They include:

- Temperature and humidity design criteria

- Winter classroom – Maintain 72°F and 40-50% RH

- Summer classroom – Maintain 75°F and 50-60% RH

- Ventilation design criteria

- Follow ASHRAE 62.1 standard

- Increase outside air to maximum

- Disable demand control

- Use outdoor IAQ sensors for outdoor pollution information

- Design guidelines for school nurse’s offices as airborne infection isolation rooms (AIIRs). School nurse’s offices are to be designed per ASHRAE Standard 170 and are to include room status monitors or room pressure monitors.

As a room pressure monitor, Dwyer recommends its Digihelic® differential pressure controller, Series DHC. This product is a 3-in-1 instrument possessing a digital display gage, control relay switches, and a transmitter with both current and voltage outputs. Combining these three features allows the reduction of several instruments with one product, saving inventory, installation time, and cost.

Series DHC units achieve a 1.5% or better accuracy on extremely low ranges, and 0.5% accuracy for ranges at or above 1 in w.c. Moreover, calibration can be performed in the field, making maintaining its accuracy more manageable.

Programming the unit is simple using the built-in menu. With scalable 4-20 mA, selectable voltage process outputs, and selectable Modbus® or BACnet communication, this controller can easily fit into your application.

As a room status monitor, Dwyer recommends the StabiliSENSE™ Series RSMC. This critical room status monitor is ideal for low differential pressure applications such as airborne infection isolation rooms, and is the perfect way to quickly and efficiently ensure rooms are at safe conditions for occupants. It does much more than monitor the differential pressure between isolation rooms and anterooms or hallways; it monitors the relative humidity, air flow and even the status of the door—whether it’s open, closed, or ajar. Additionally, the RSMC drifts less over time than other monitors, meaning there’s less recalibration.

The graphical display color changes of the StabiliSENSE™ monitor allow for a clear determination of when the parameters are operating within the acceptable range (green), caution range (yellow), or have gone outside the acceptable operating range (red). Each RSMC can monitor up to three rooms and displays up to four parameters.

Finally, given its slim design, the StabiliSENSE™ room status monitor can be installed flush in walls with space constraints, due to its shallow mounting depth of 1.1″ (27.5 mm).

To learn more about StabiliSENSE™ monitors and how they can be used in your application, please visit our website.